Pipe cutting deice

A cutting device and pipe material technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of time-consuming and power consumption, and achieve the effect of energy saving, non-rough section and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

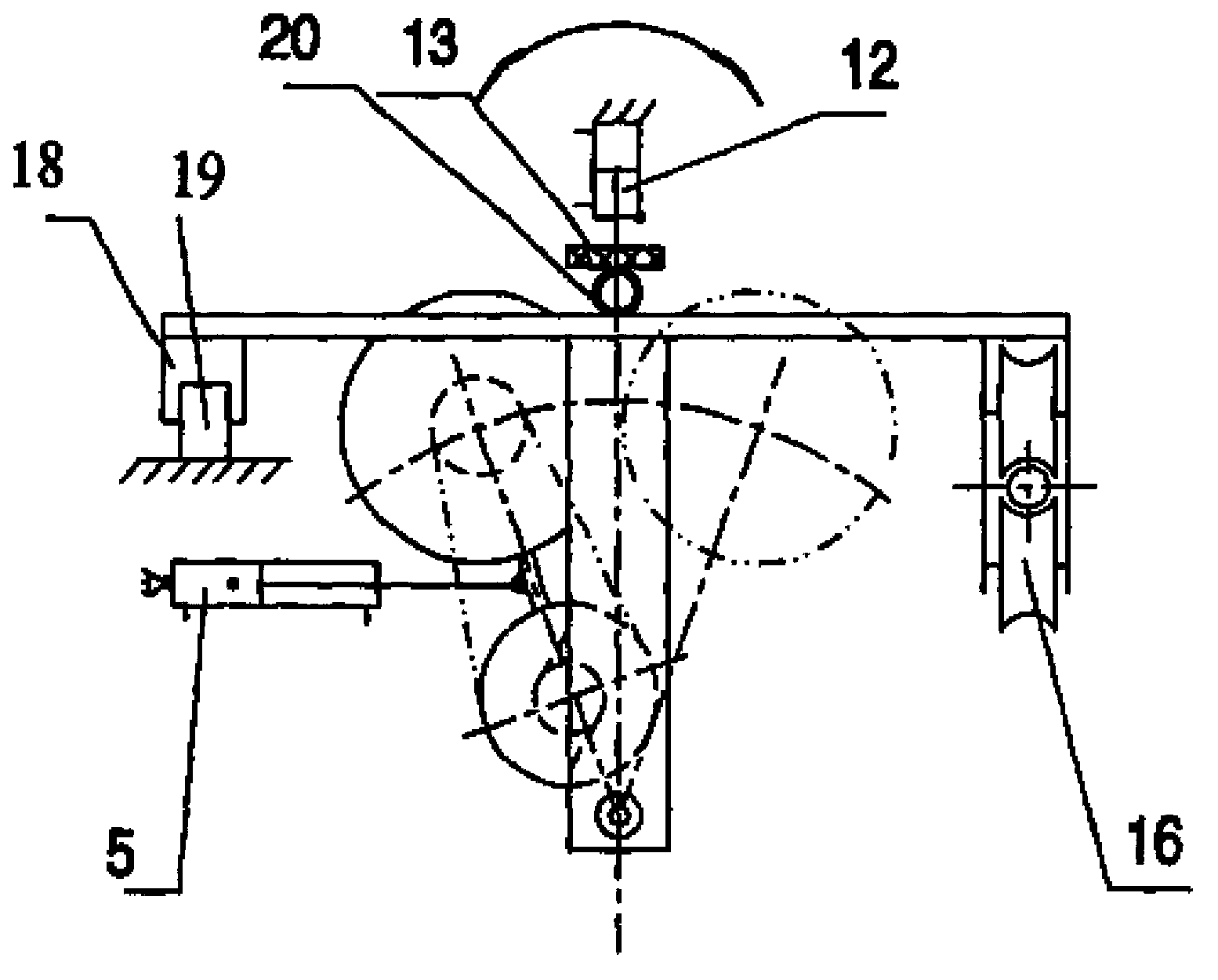

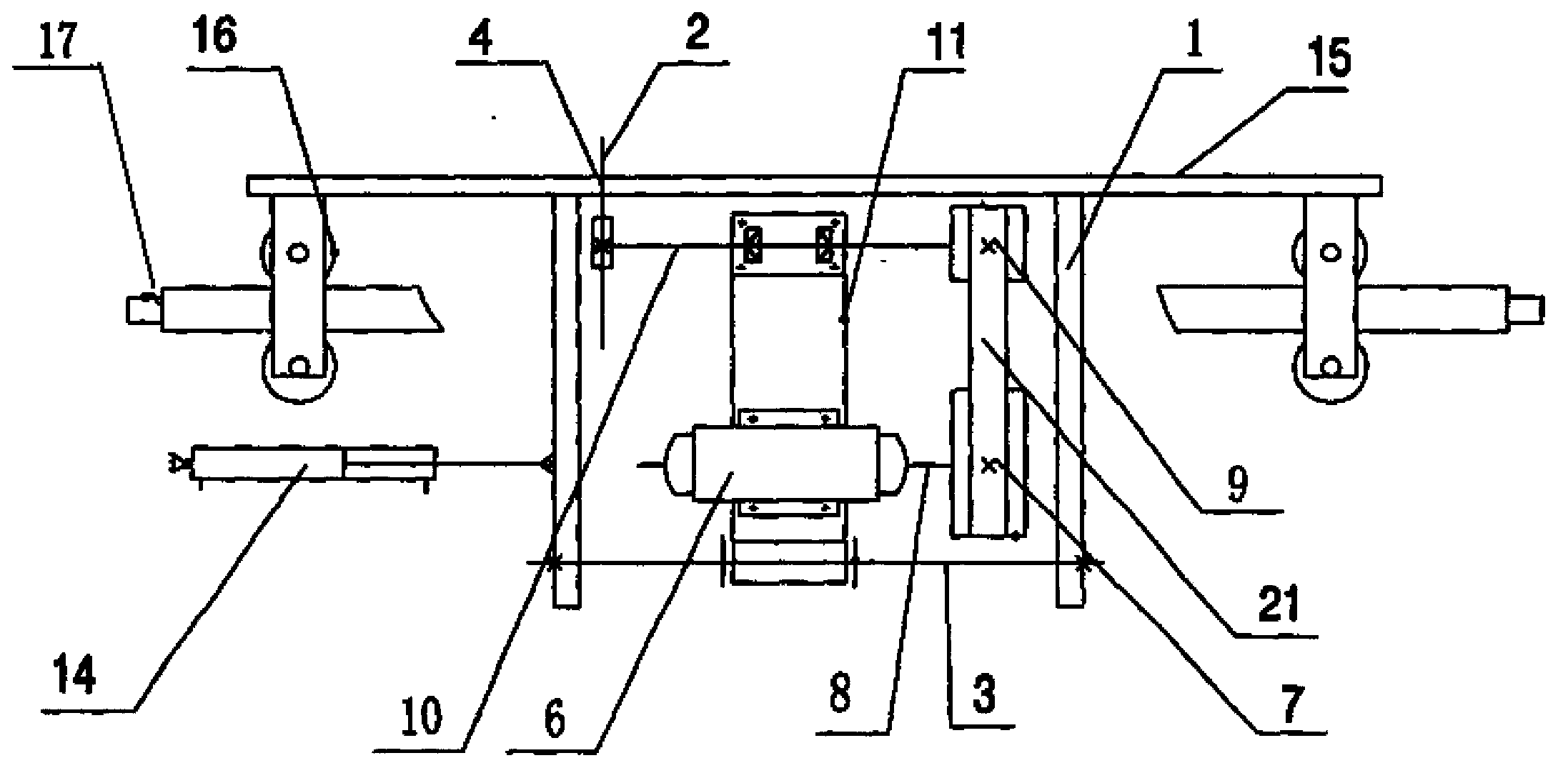

[0013] see figure 1 with figure 2 , a pipe cutting device, comprising: a frame 1 and a cutting assembly, the frame 1 includes a working platform and a rotating shaft 3, and the cutting assembly is installed on the rotating shaft 3 on the frame 1 consistent with the running direction of the pipe 20, the The rotating shaft 3 is fixedly connected with a swinging device, so the rotating shaft 3 is the swinging shaft of the cutting assembly, and the working platform is provided with a notch 4 that accommodates the swinging of the cutting assembly, wherein the cutting assembly includes a saw blade 2, a belt drive wheel and Drive motor 6, and saw blade 2 is higher than working platform, and the driving pulley 7 of described belt transmission wheel is connected with motor shaft 8, and the driven wheel of belt pulley is connected with saw blade 2 through saw blade shaft 10.

[0014] As a preferred solution, the oscillating device is a cutting cylinder 5 .

[0015] As a preferred sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com