Assembling machine

An assembly machine and assembly table technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, low degree of automation, difficulty in achieving angle and position accuracy, and improve stability and reliability. , the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

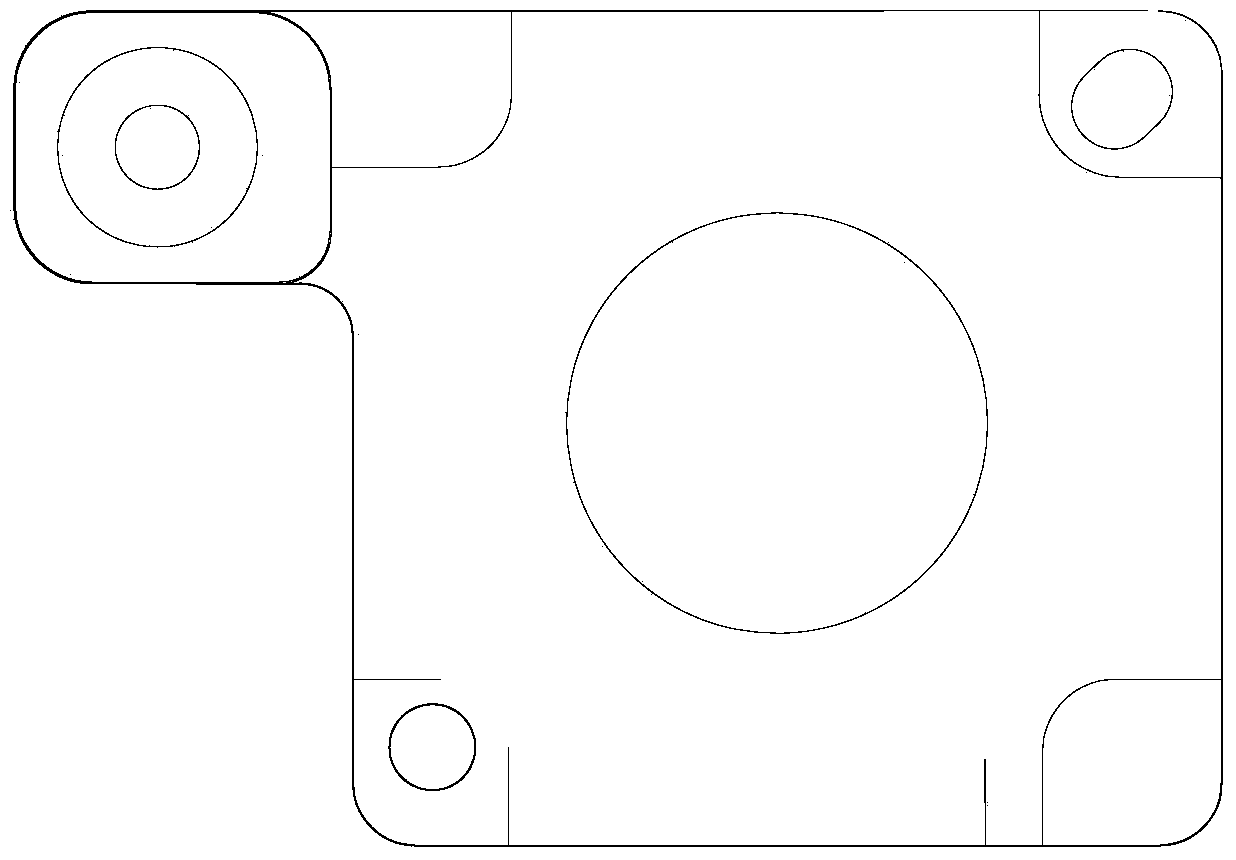

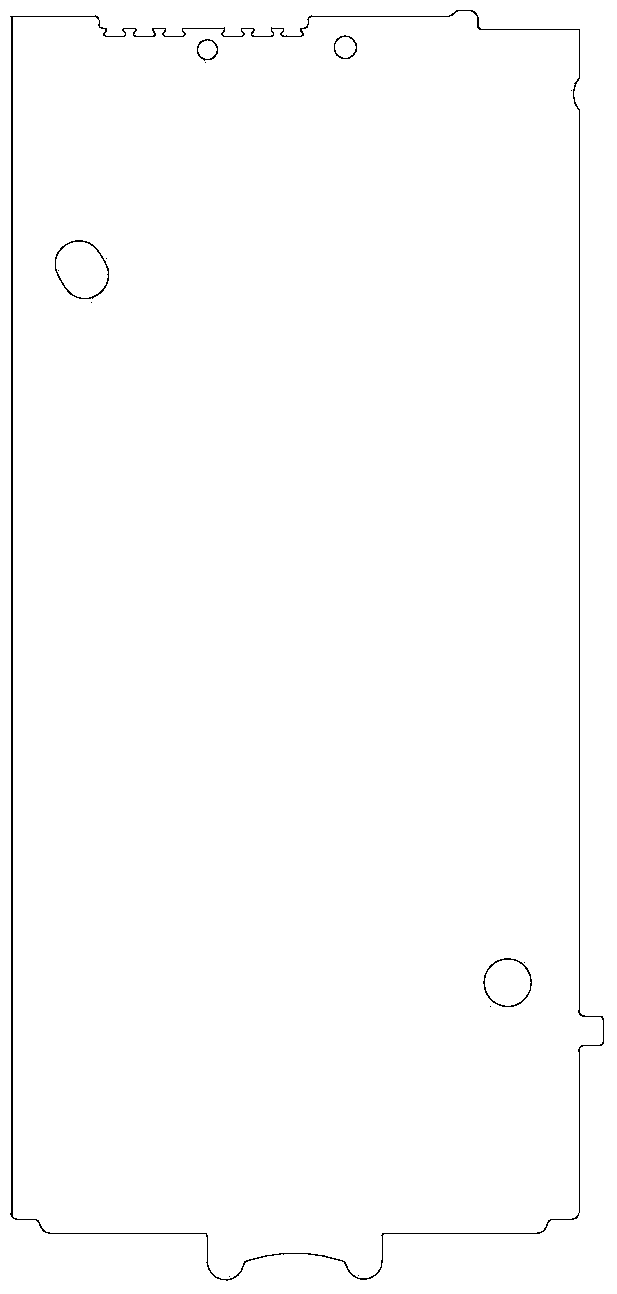

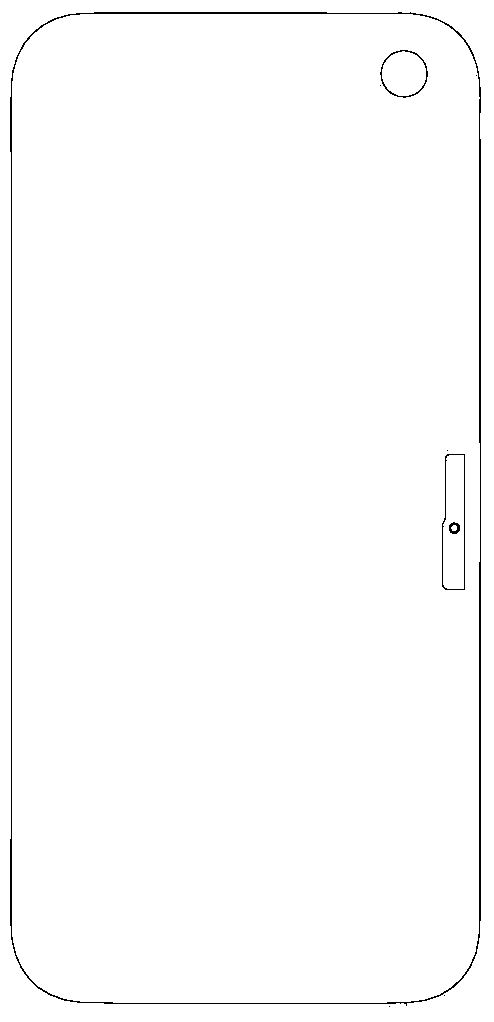

[0017] Figure 4 A specific embodiment of this assembly machine of the present invention is shown, which includes a frame (not shown in the figure), an assembly platform 1 located on the top of the frame, a robot arm 2, and a robot arm controller (not shown in the figure). drawn), where the robotic arm is mainly used to grab the workpiece A (Rcam) and the workpiece B (Housing) to be assembled, and the robotic arm controller is mainly used to control the movement of the robotic arm.

[0018] A push-pull movable frame (not shown in the figure) is installed on the assembly table 1, and when a pushing or pulling force is applied to the movable frame, it can move forward and backward. The movable frame is provided with two material seats 3 for fixing the workpiece C to be assembled (that is, the product body mentioned in the background technology), and the two material seats 3 are distributed one after the other on the movable frame. During use, the workpiece C to be assembled can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com