Improved glass polishing machine

A polishing machine, an improved technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of the inability to reach the polishing liquid quickly, the stability is not enough, and the production is inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

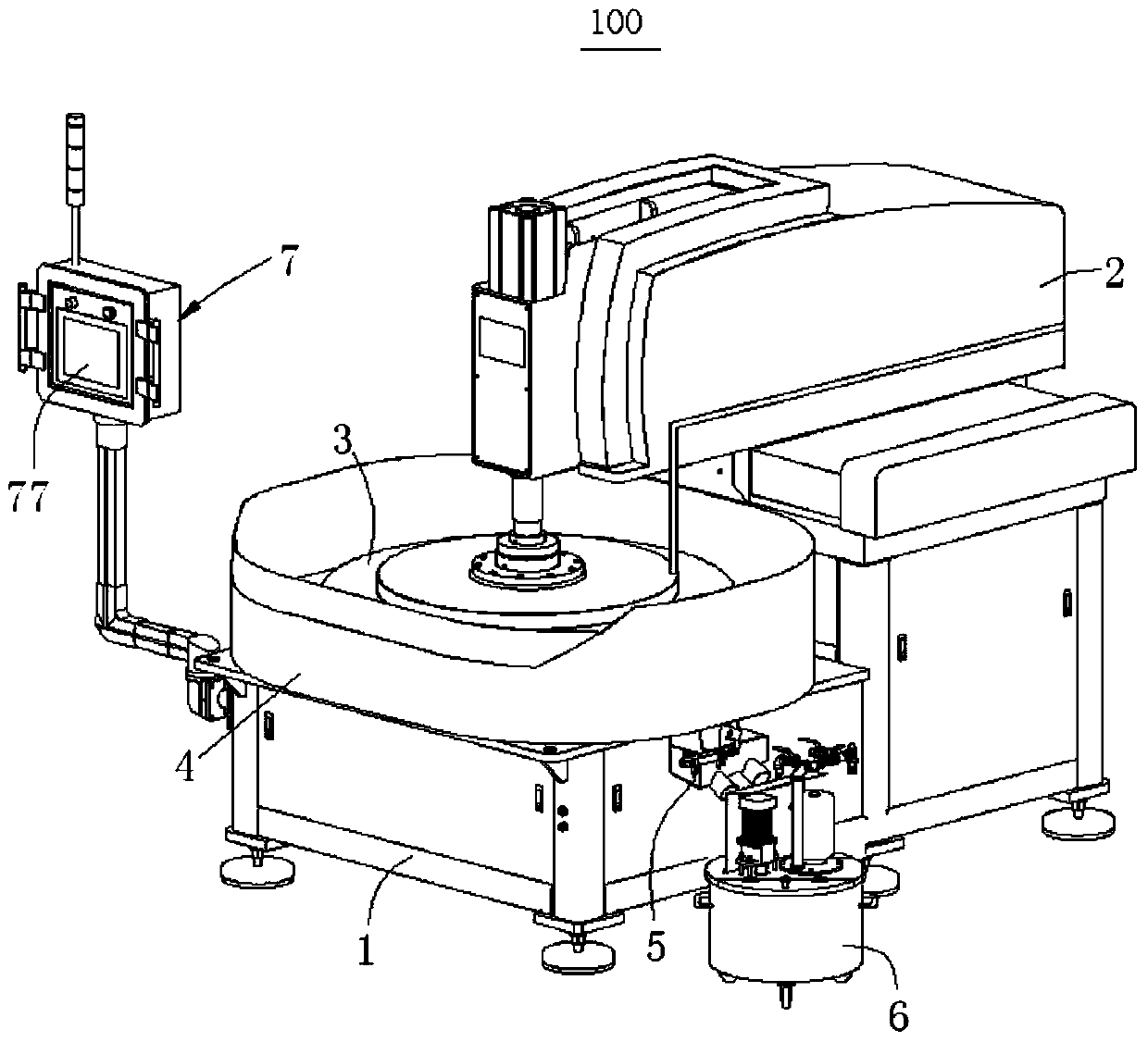

[0096] see figure 1 , the present invention provides an improved glass polishing machine 100, which includes a base 1, an upper fixed plate module 2, a lower fixed plate module 3, a liquid receiving plate 4, an automatic liquid-water separation device 5, a polishing liquid recovery bucket 6 and Programmed control system7.

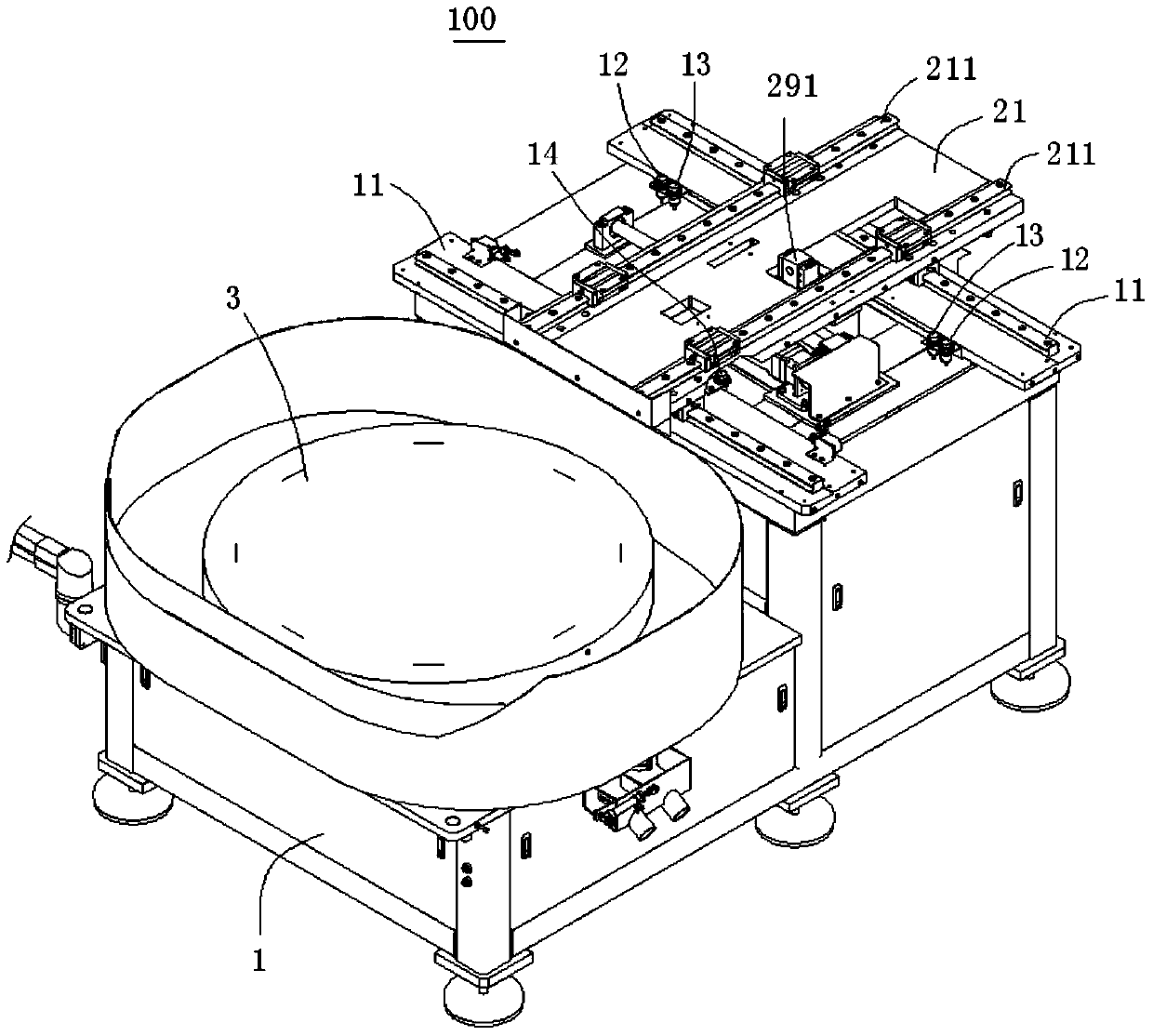

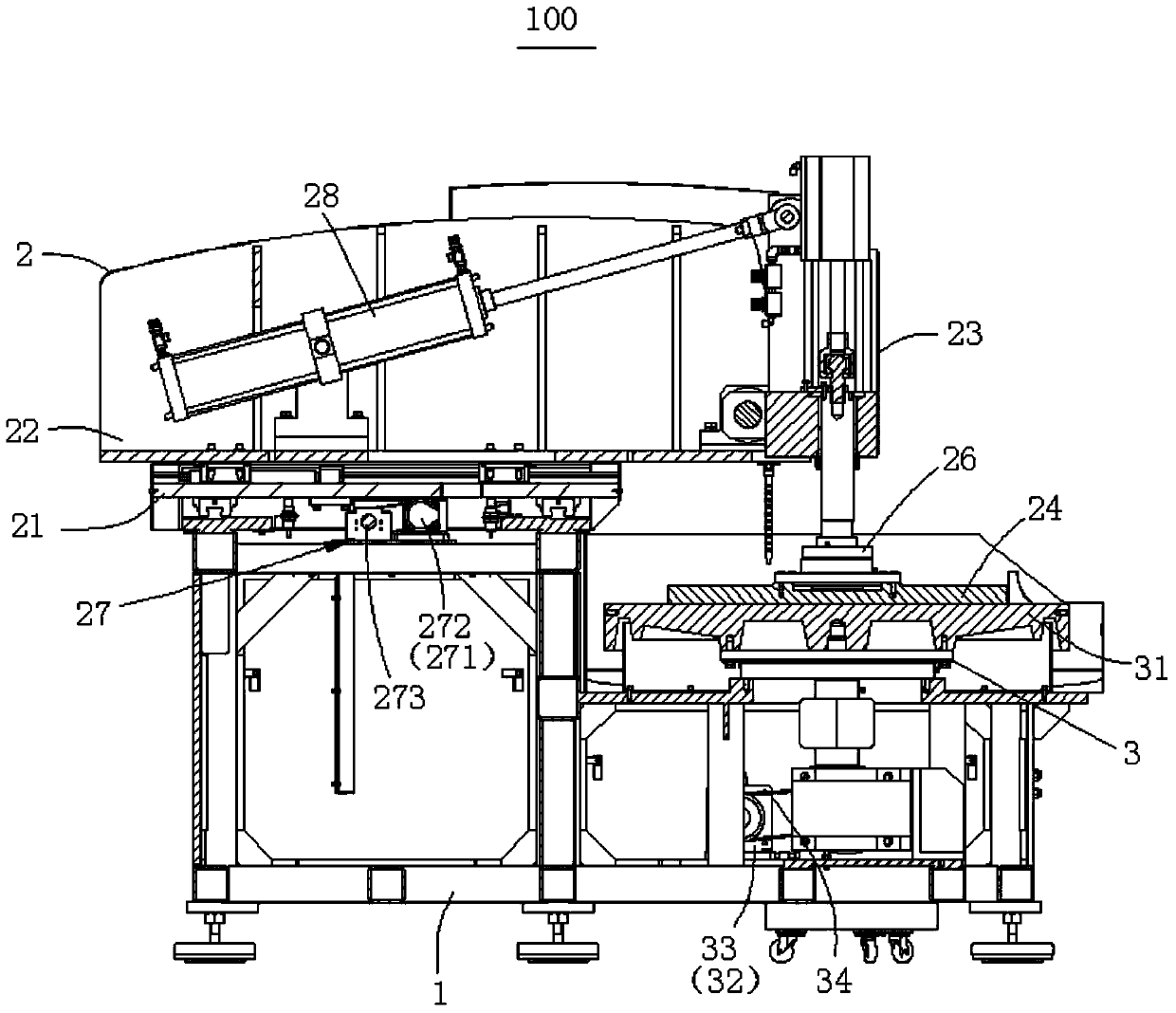

[0097] see Figure 1 to Figure 3 The base 1 is provided with two transverse slide rails 11 for sliding installation of the upper fixed plate module 2, and a plurality of travel switches (12, 13, 14 and 15), specifically, in this embodiment, the travel switch includes two limit position stop switches 12 arranged near the two ends of the transverse slide rail 11, and two deceleration switches located inside the limit position switch 13, and a middle position stop switch 14 corresponding to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap