An automatic phase separation system and automatic phase separation method for electrified railway divisions

An automatic over-phase, electrified railway technology, applied in power lines, transportation and packaging, vehicle components, etc., can solve the problem that the current transformer cannot detect the train passing signal, reduce the train speed and capacity, and the train cannot receive current. , to achieve the effect of reliable uninterrupted power, automatic over-phase, simple structure and control, and fewer actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

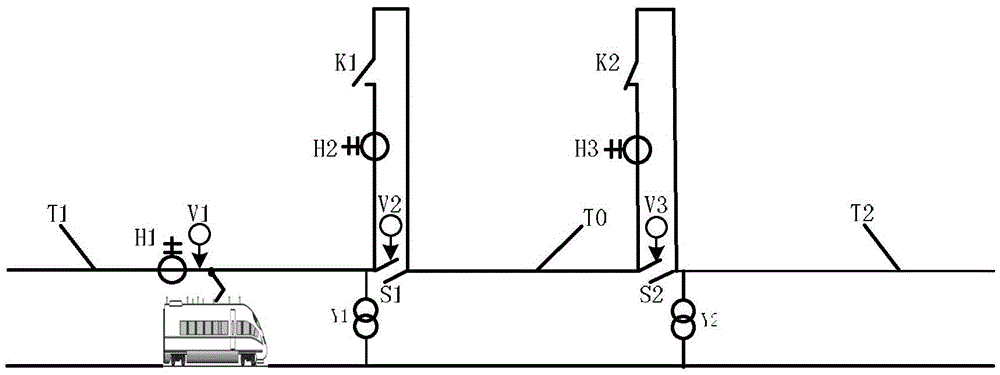

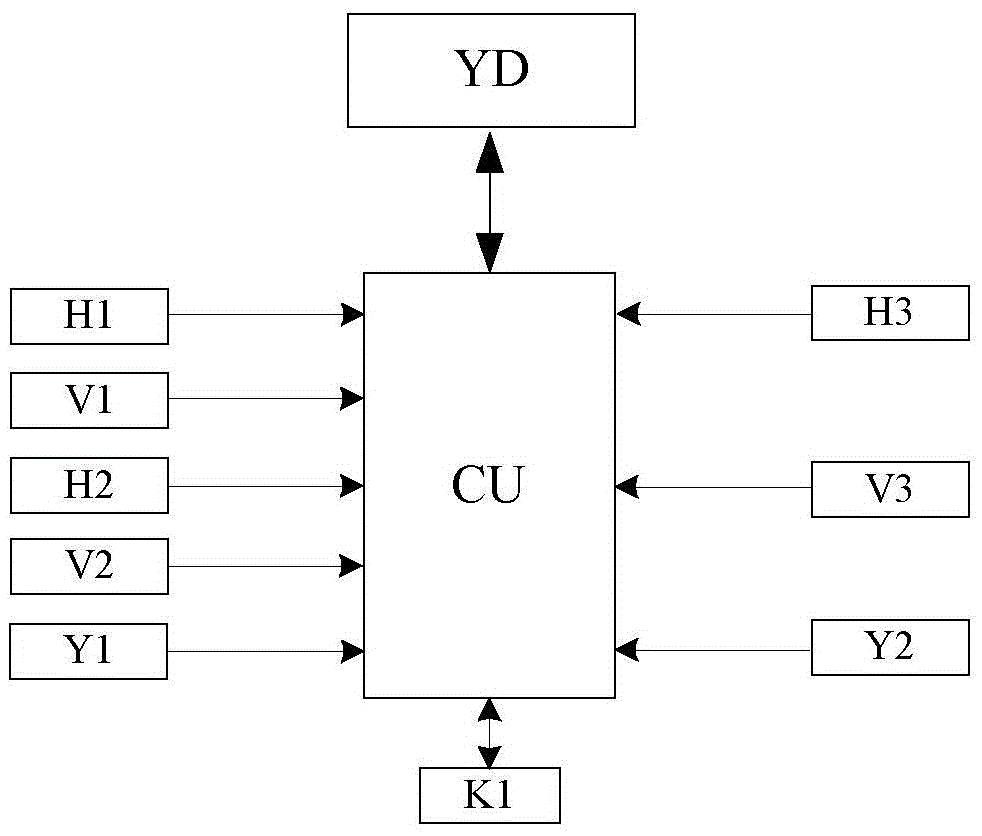

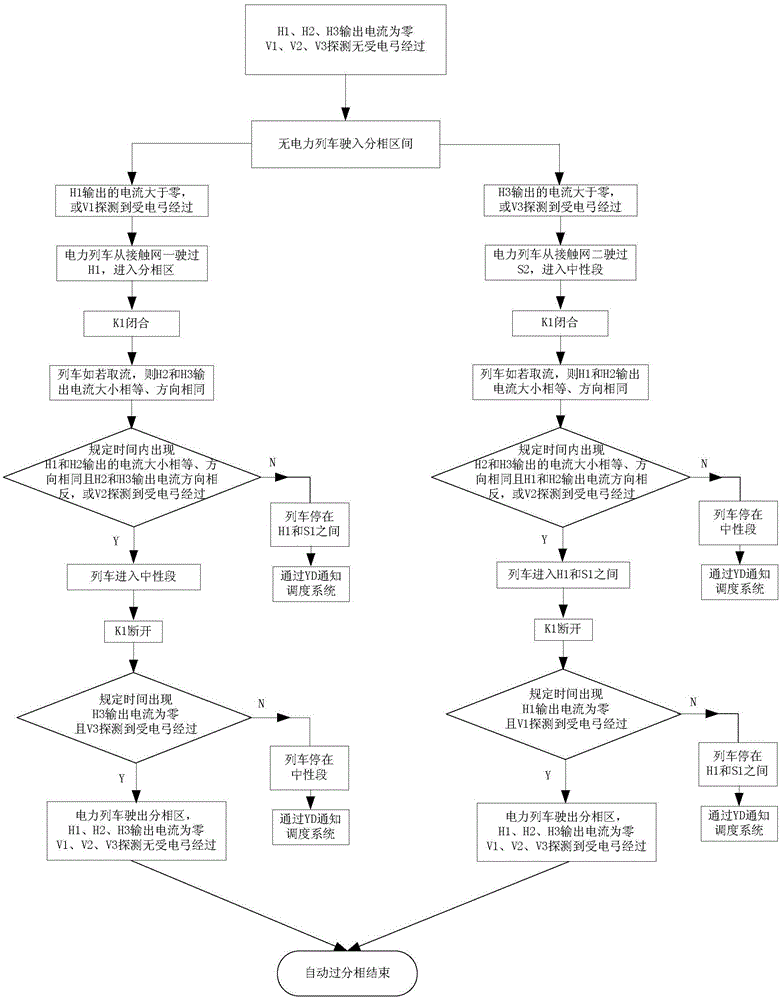

[0036] figure 1 , 2 It shows that a specific embodiment of the present invention is an automatic phase separation system for electrified railway divisions, including catenary one T1, catenary two T2, and neutral section T0, and catenary one T1 passes through electric segment one S1 Connected with the neutral section T0, the catenary 2 T2 is connected with the neutral section T0 through the electrical segment 2 S2, wherein: the catenary 1 T1 is connected in series with the current transformer 1 H1 near the electrical segment 1 S1; the current transformer 2 H2 and normally open switch one K1 are connected in series and then connected in parallel on electric segment one S1; current transformer three H3 and normally closed switch two K2 are connected in series and then connected in parallel on electric segment two S2; current transformer one H1 Pantograph Detector 1 V1 is installed on the pillar of S1, Pantograph Detector 2 V2 is installed on the pillar at Electric Section 1 S1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com