Three-pillar support-type superstructure of unmanned surface vehicle

A superstructure, support technology, applied in superstructure, ship, ship construction and other directions, can solve the problems of lack of dynamic stability, anti-overturning sensing equipment sensing efficiency, difficulty in maintaining motion stability, and reduced ship navigation performance, etc. Achieve significant anti-overturning ability, reduce sway characteristics and improve longitudinal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

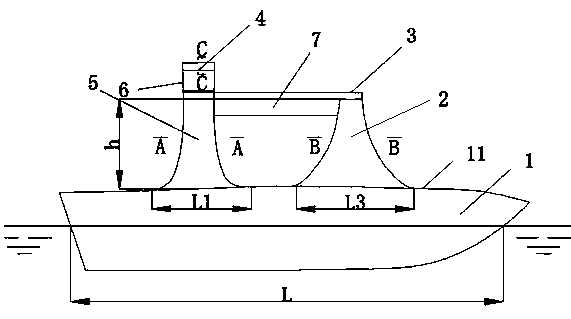

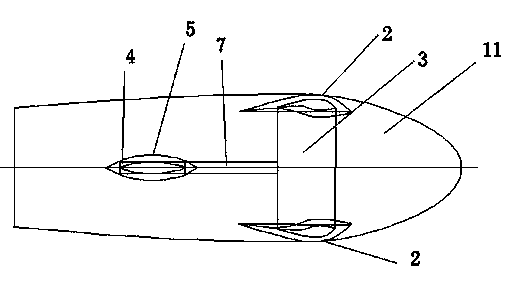

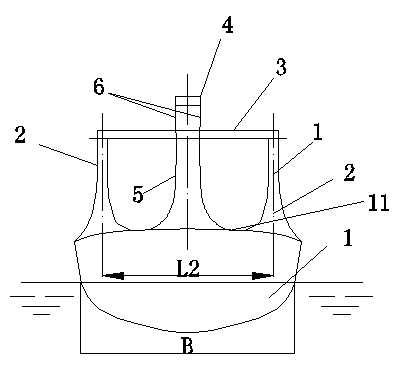

[0018] see Figure 1-3 , the surface unmanned vehicle includes the main hull 1, the design waterline length of the main hull 1 is L, and the design waterline width is B.

[0019] Two front pillars 2 and a rear pillar 5 are arranged on the deck 11 of the main hull 1, and the bottoms of the two front pillars 2 and a rear pillar 5 are all vertically fixed on the deck 11. Two front pillars 2 and a rear pillar 5 are fully enclosed pillar structures. Two front pillars 2 are symmetrical with respect to the left and right width direction of the main hull 1, and a rear pillar 5 is located in the middle of the main hull 1 in the left and right width direction.

[0020] The two front pillars 2 are located at the forward (1 / 6-1 / 4) L position of the midship, and the rear pillar 5 is located at the rear (1 / 6-1 / 4) L position of the midship. The bottom length L1 of the rear pillar 5 is (1 / 6-1 / 5) L, the height h of the rear pillar 5 is 2 / 3-13 / 7 of the design waterline length, the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com