Adjusting device for a beverage filling system and method for cleaning an adjusting device

A technology for adjusting devices and filling equipment, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., capable of solving problems such as large construction spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A preferred exemplary embodiment is described below with the aid of figures. In this case, identical, similar or identically acting elements are provided with identical reference signs in the different figures, and a repeated description of these elements is partially omitted in the ensuing description in order to avoid redundancy in the description.

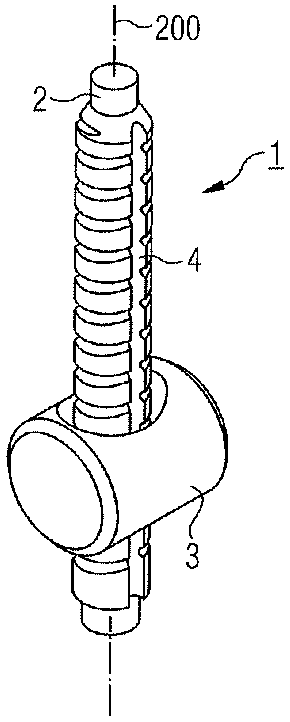

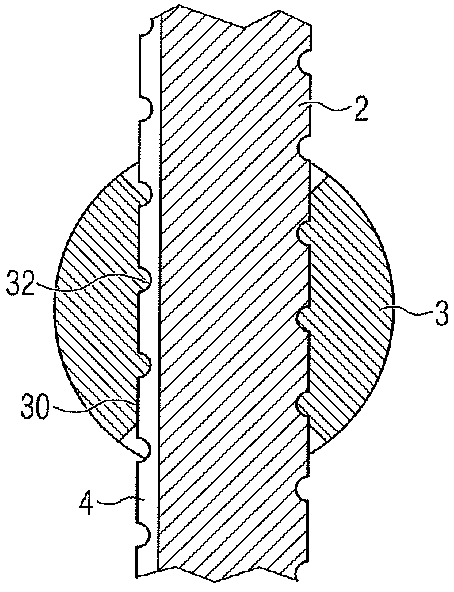

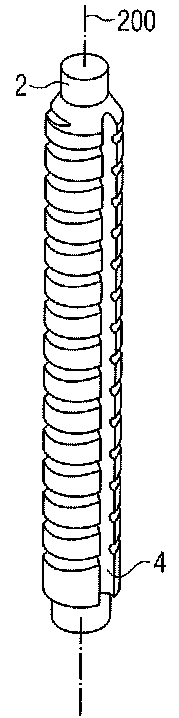

[0044] figure 1 An adjustment device 1 is shown in a schematic perspective view, which has a rotary element 2 in the form of a spindle and a translation element 3 in the form of a nut. figure 1 The schematically shown adjusting device 1 is correspondingly a screw drive, which is used, for example, for linear adjustment between two machine elements of a beverage filling plant.

[0045]A cleaning groove 4 is provided in the rotating element 2, which cleaning groove is figure 1 In the exemplary embodiment shown, a recess extending in the direction of the rotational axis 200 of the rotary element 2 and open to the outside i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com