Medical repairing mesh and manufacturing method thereof

A mesh and mesh technology, applied in the field of medical repair mesh and its manufacturing, can solve the problems of low mechanical strength, heavy fabric, unfavorable tissue growth material exchange, etc., and achieve the effects of reducing production cost and simple manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

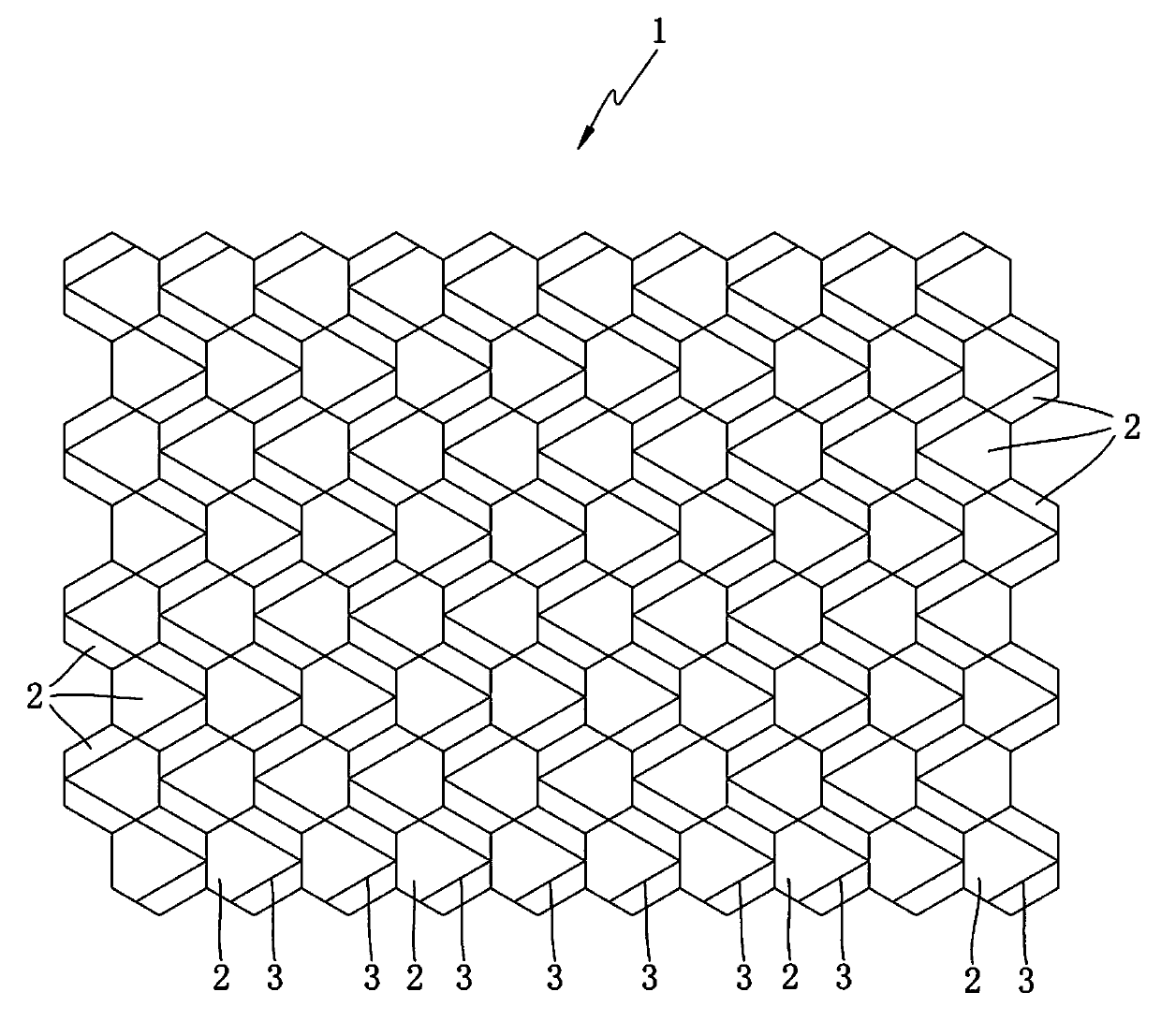

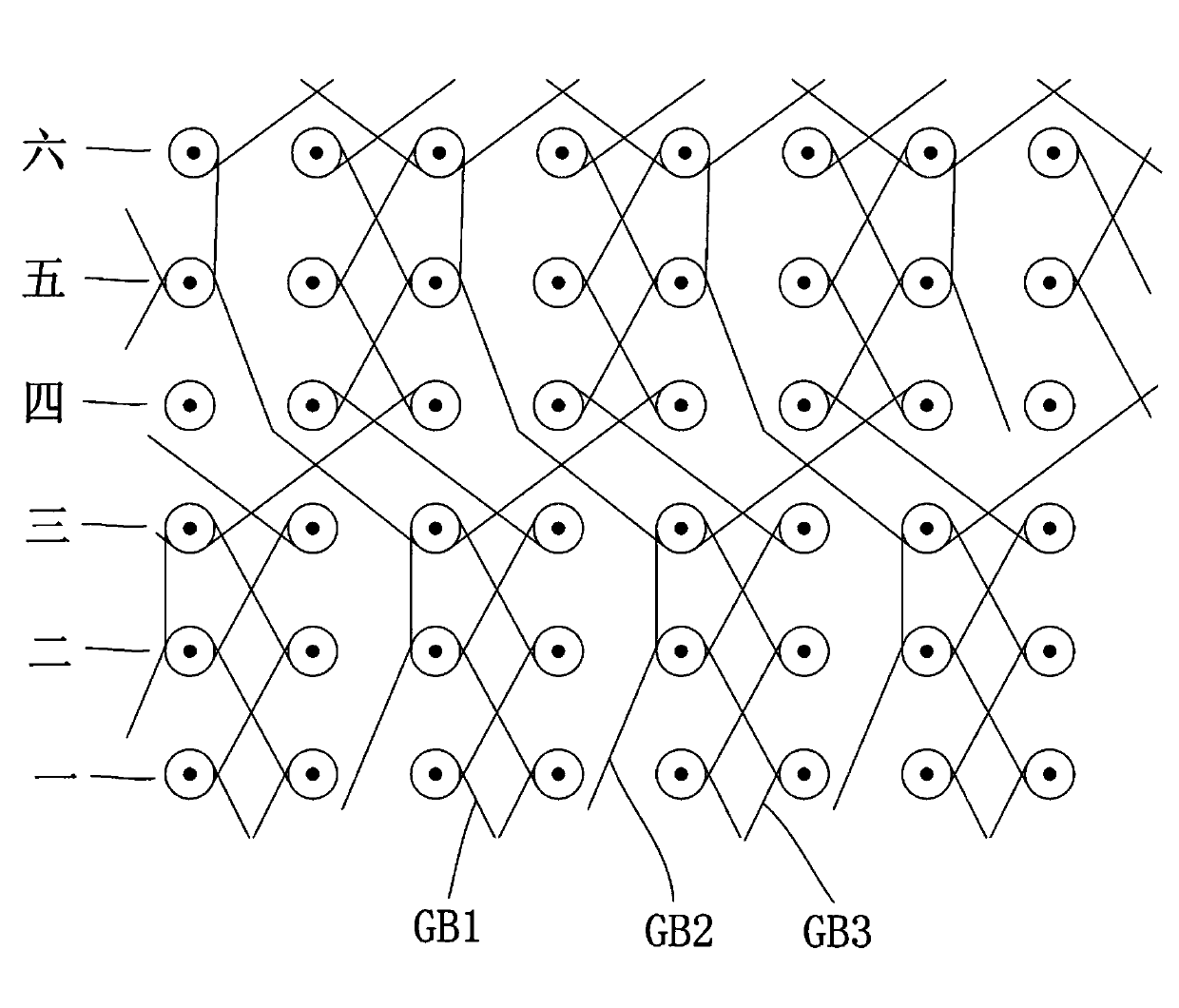

[0017] As a preferred embodiment of the present invention, the area of each hexagonal mesh 2 is 4-18mm 2 , the weight per unit area of the warp knitted mesh fabric 1 is 30-34 g / m 2 . This kind of mesh is light and thin, so that the patient feels less foreign body sensation during use.

[0018] In the present invention, the diameter of the polypropylene monofilament is 0.1-0.2mm, preferably 0.1mm, the breaking strength of the polypropylene monofilament is 5.70cN / dtex, and the elongation at break is 22.7%. Each of the The shape of the hexagonal mesh 2 is preferably a regular hexagon, and the area of each hexagonal mesh 2 is preferably 5.8-16.2mm 2 , that is, the aperture (ie, circumcircle diameter) of each hexagonal mesh 2 is 3-5 mm. This kind of mesh is light and thin, and patients feel little foreign body sensation during use, and the mesh has a high porosity, with a porosity greater than 72%, which can well meet the requirements of light weight and tissue growth mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com