Cooperative action control method, device and system of moving parts

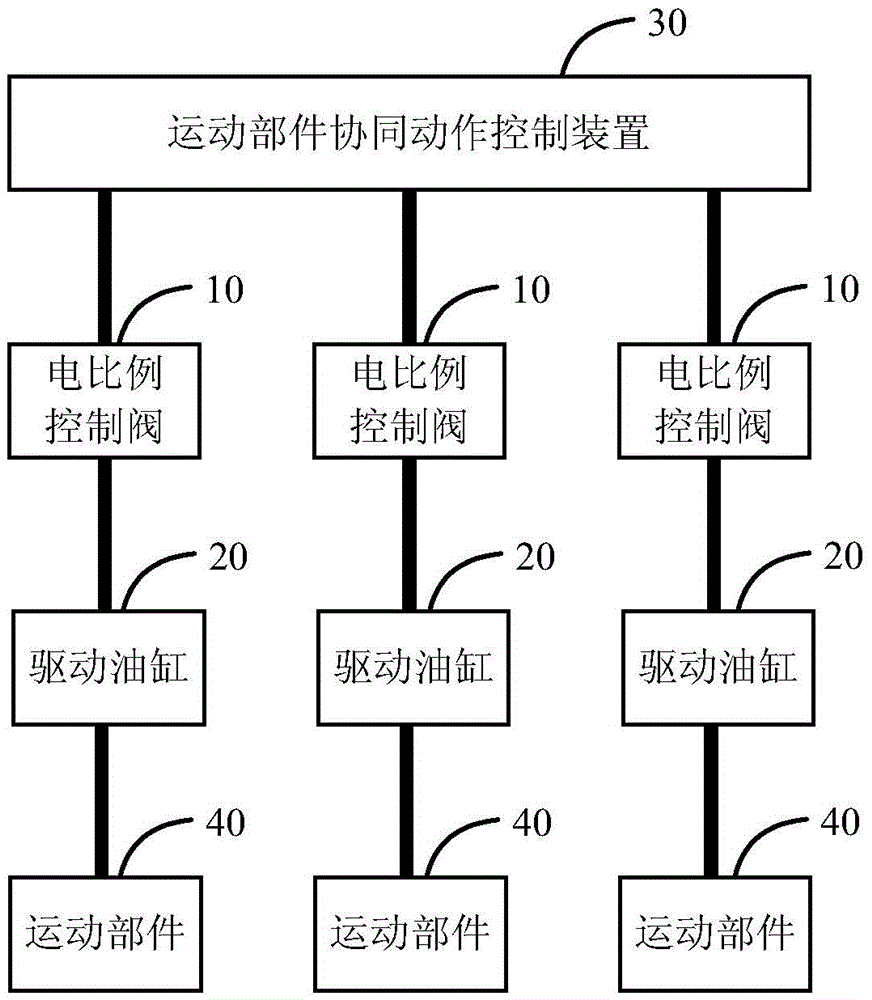

A technology of moving parts and coordinated actions, which is applied in the direction of fluid pressure actuators, servo motor components, servo motors, etc., and can solve the problem of poor control accuracy of the action coordination of multiple moving parts and inaccurate control of the response time of multiple driving cylinders , Low accuracy of motion trajectory control of multiple moving parts, etc., to achieve the effect of improving accuracy, reducing time error, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

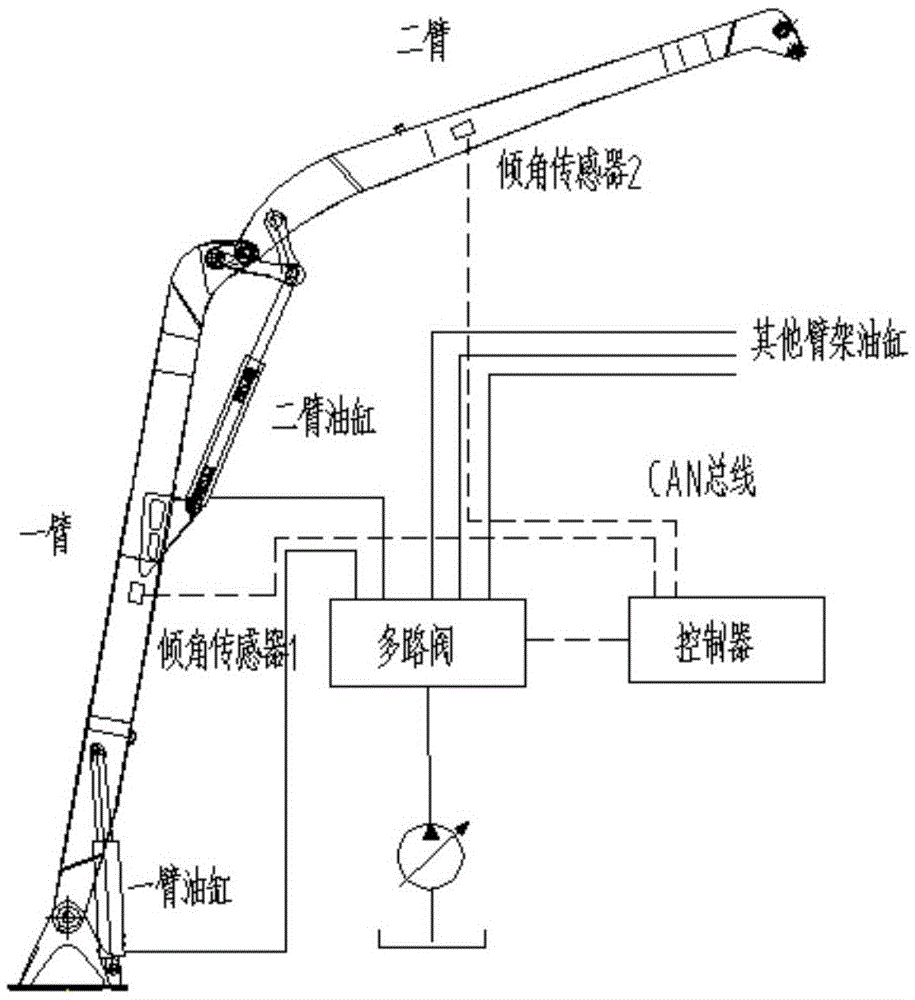

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 of the present invention provides a method for controlling coordinated actions of moving parts, the flow of which is as follows Figure 6 shown, including the following steps:

[0084] Step S101: Applying a preparatory current smaller than an activation current threshold to each electric proportional control valve of the multi-way valve, so that each electric proportional control valve of the multi-way valve is in a ready state.

[0085] The multi-way valve that controls the action of the driving cylinder is controlled by a current signal, and each electric proportional control valve has a current dead zone. During the control process of the multi-way valve, due to the influence of various factors, the The spools have different responses. In order to make the spools of the electric proportional control valves respond simultaneously, the present invention adopts a "preparation" current mode. In order to make multiple moving parts cooperate, after the cooper...

Embodiment 2

[0099] The method for controlling the coordinated action of moving parts provided by Embodiment 2 of the present invention further increases the control of the action time of each electric proportional control valve on the basis of the method of Embodiment 1, thereby further improving the coordination and consistency of the actions of multiple moving parts. Process such as Figure 7 shown, including the following steps:

[0100] Step S201: Applying a preparatory current smaller than an activation current threshold to each electric proportional control valve of the multi-way valve, so that each electric proportional control valve of the multi-way valve is in a ready state.

[0101] Refer to step S101, which will not be repeated here.

[0102] Step S202: Determine the action time of the control current on each electric proportional control valve according to the response delay time of each driving oil cylinder relative to the corresponding electric proportional control valve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com