Improved structure of lifting oil cylinder block one-way valve

A technology for lifting oil cylinder and one-way valve, which is applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problems of difficult processing, affecting buffer effect, complex structure of oil cylinder block and valve sleeve, etc. Achieve the effect of ingenious structure, simple structure improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

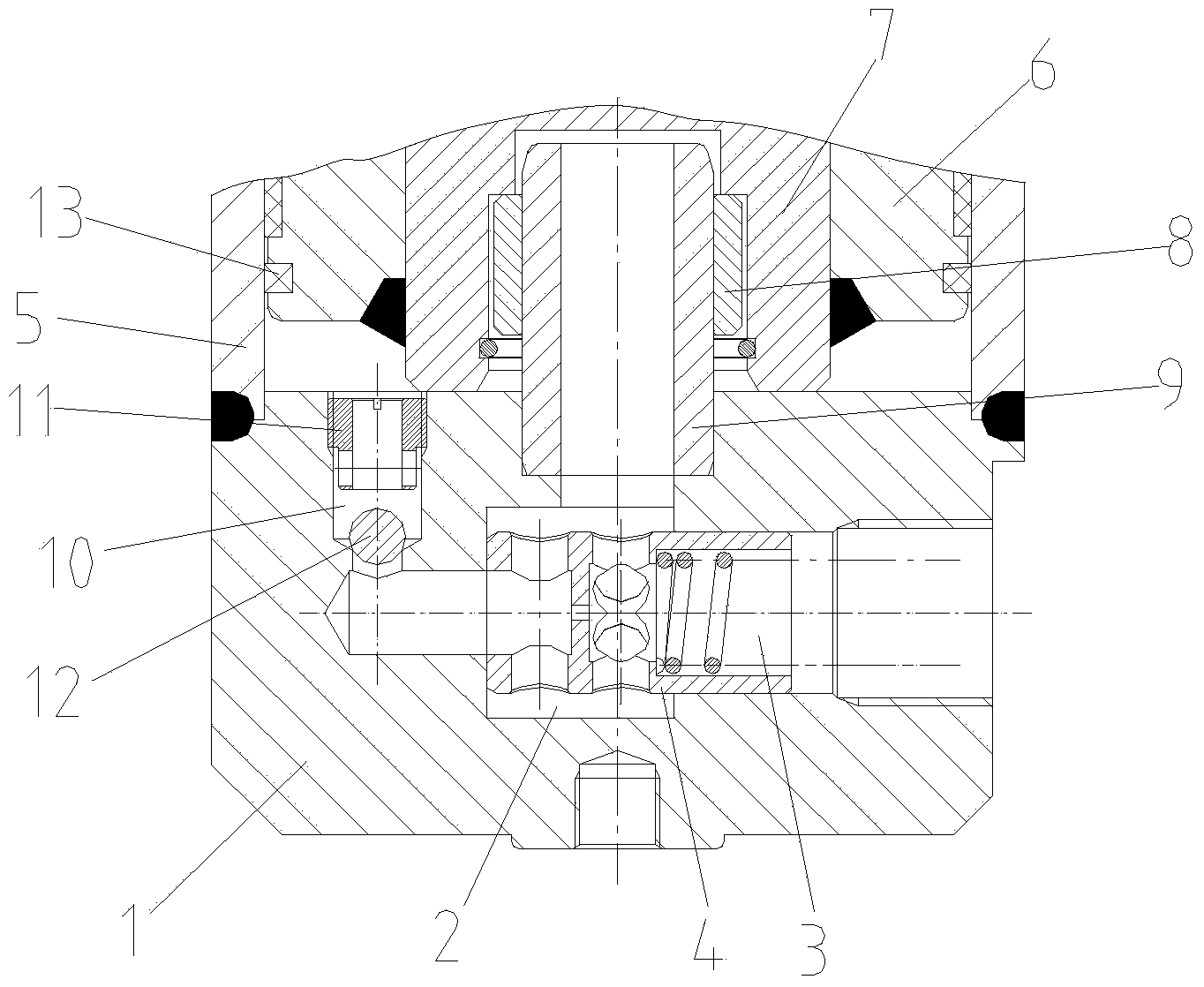

[0010] Such as figure 1 As shown, an improved structure of the one-way valve of the cylinder seat of the lifting cylinder includes a cylinder seat 1, an oil chamber 2 is arranged laterally in the cylinder seat 1, and an oil chamber opening is provided on one side of the cylinder seat 1, and the oil chamber A valve stem 3 is slidingly installed inside the valve stem 3, a valve sleeve 4 is installed on the valve stem 3, an oil outlet connected with the oil chamber 2 is vertically opened on the top of the cylinder seat 1, and a cylinder barrel 5 is installed on the cylinder seat 1, and the cylinder barrel 5 A piston 6 is vertically slid in the middle, a piston rod 7 is installed in the piston 6, a buffer valve sleeve 8 is installed in the piston rod 7, a buffer plunger 9 is arranged in the buffer valve sleeve 8, and the bottom end of the buffer plunger 9 extends into the cylinder. In the oil outlet of the seat 1, the top of the cylinder seat 1 on the side of the oil outlet is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com