Detachable hinge pin connecting structure for pipe connecting

A connection structure and pipe connection technology, applied in the direction of connecting components, rod connections, mechanical equipment, etc., can solve problems such as endangering the safety of mechanical structures, weakening the strength of male and female joints, and adhesion and wear, reducing material and labor waste, The effect of meeting the requirements of loading and unloading and reducing the contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

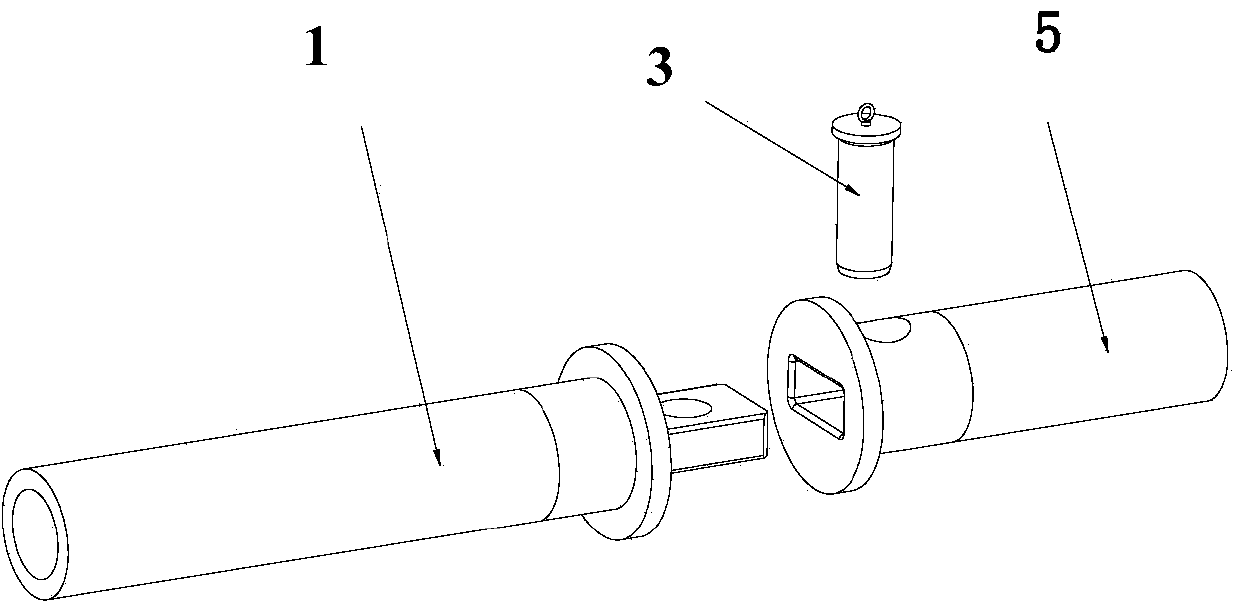

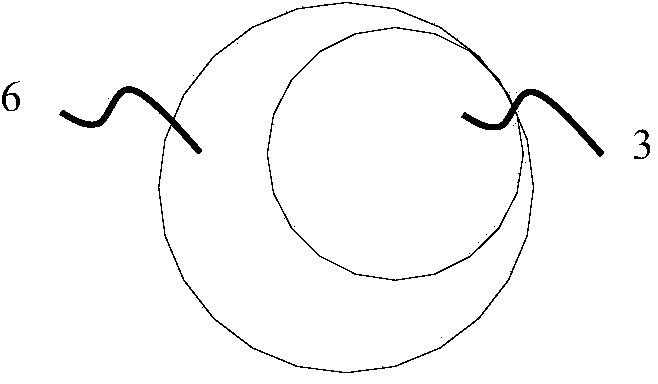

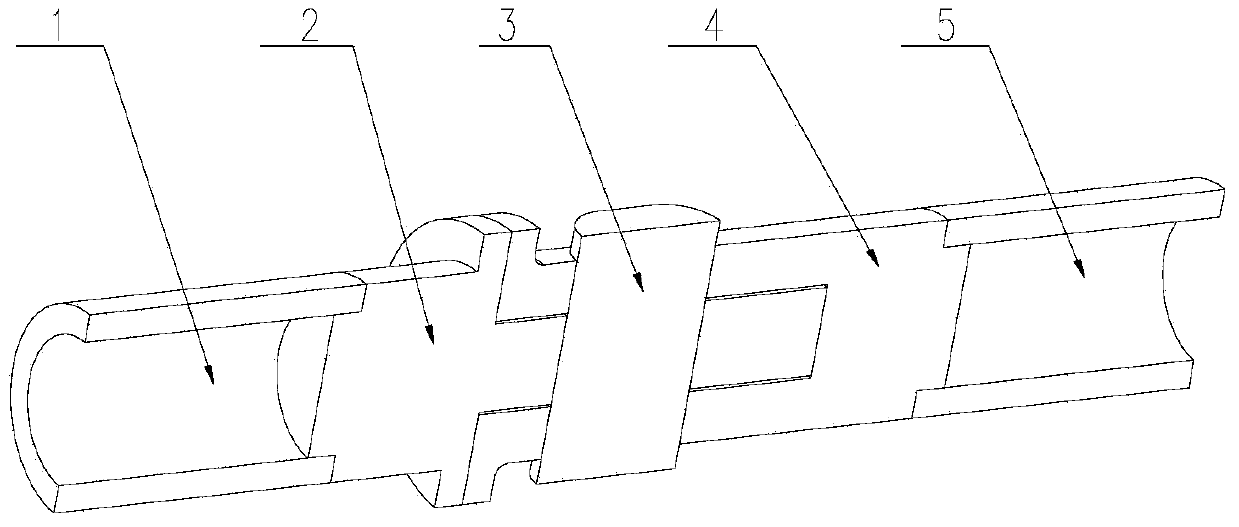

[0020] see image 3 , the present invention provides a detachable pin connection structure for pipe connection, including a pin 3, a male joint 2, and a female joint 4 compatible with the male joint 2; both the male joint 2 and the female joint 4 are provided with There is a pin hole 6 for the insertion of the pin 3, and there is at least one surface contact between the pin 3 and the pin hole 6. For the structural diagram of the relationship between the pin 3 and the pin hole 6, please refer to Figure 4 as well as Figure 5 , the pin 3 can be cylindrical, the same as the existing pin; it can be Figure 5 The structure shown is a racetrack-shaped flat pin; no matter what the structure of the pin is, it is necessary to ensure that there is a surface contact at the part that contacts the pin hole.

[0021] The section of the contact surface between the pin hole 6 and the pin 3 is arc-shaped, and the radius of the arc of the pin 3 is the same as that of the pin hole 6 . Pin 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com