Ignition device of hydrogen chloride synthetic furnace and ignition method thereof

A technology of an ignition device and a synthesis furnace, which is applied to the ignition, combustion ignition, combustion method and other directions using electric sparks, can solve the problems of insufficient mixing of air and hydrogen, the flame is easily blown away by the airflow, and the ignition success rate is low, etc. Improvement of ignition method and ignition control system, compact structure and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

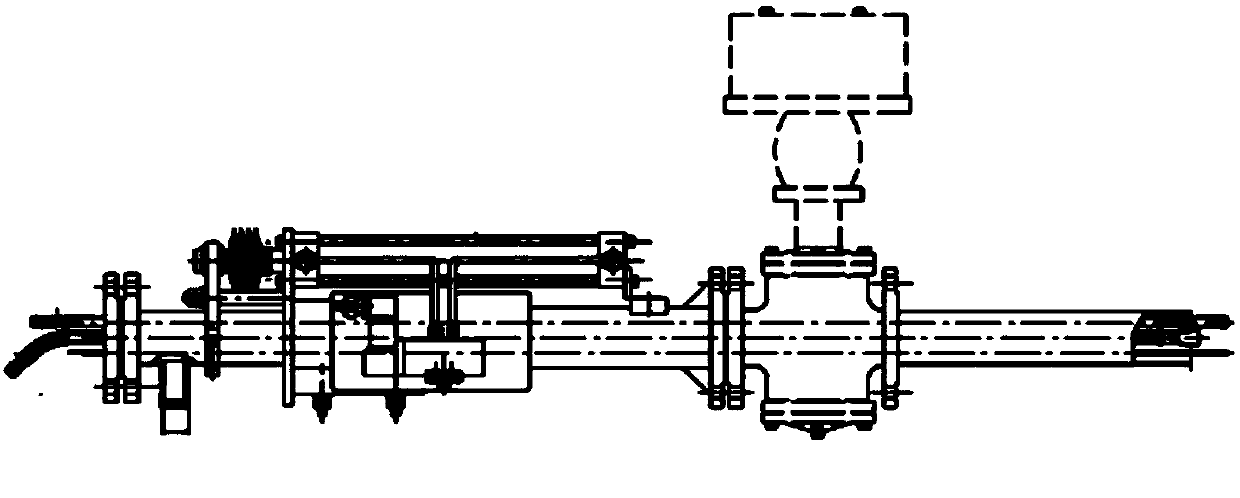

[0033] see figure 2 , the ignition has no moving parts. As can be seen in the figure, the ignition device of the hydrogen chloride synthesis furnace includes a cylindrical casing, the cylindrical casing is divided into a furnace inner section and a furnace outer section, and is connected by a flange 6; the cylindrical casing furnace An air connection port 5 is provided on the outer section; an arc ignition gun 17, a gas pipe 8, and a flame probe 12 are arranged in parallel in the cylindrical casing, and the length of the flame probe 12 is longer than the gas pipe 8, Arc ignition gun 17, the armored thermocouple of the flame probe head;

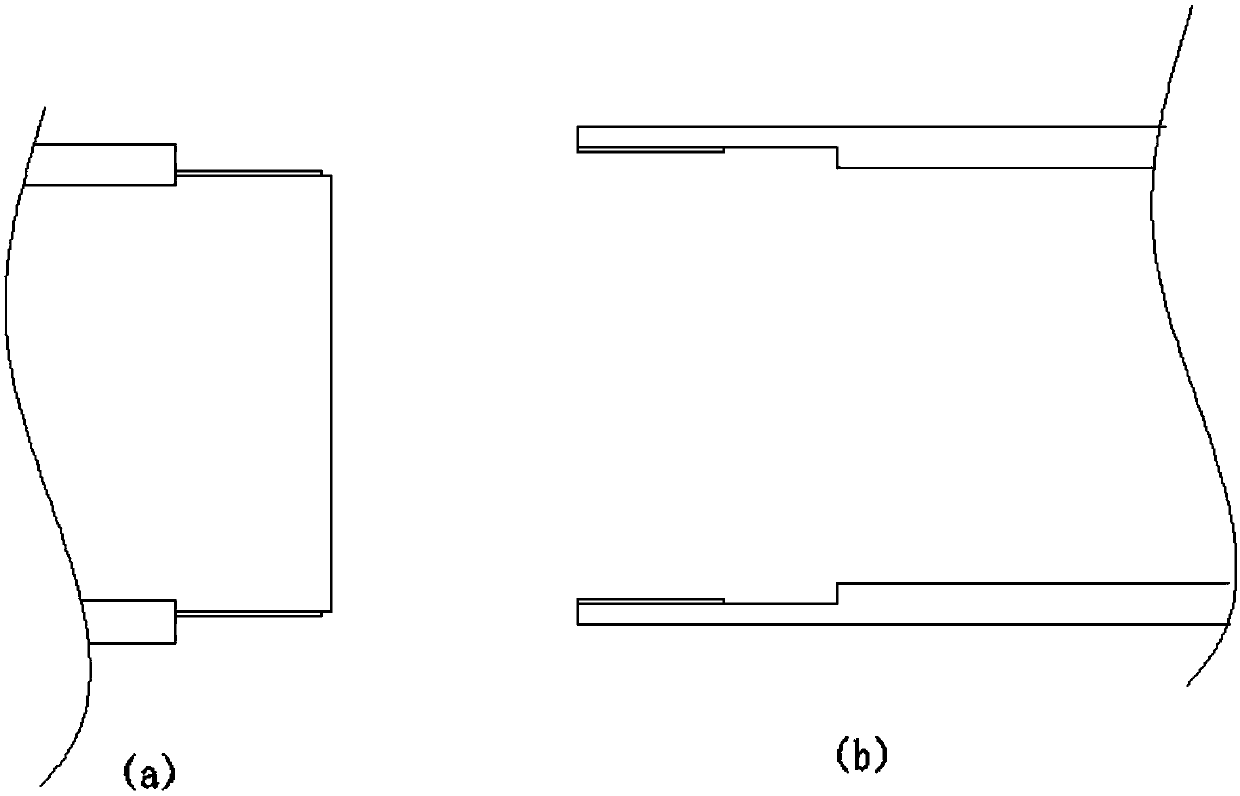

[0034] see image 3 , 4 , the furnace inner section of the cylindrical casing includes a front sleeve 13 and a rear sleeve 7, the front sleeve 13 is screwed to the rear sleeve 7, and the swirl plate 11 is pressed and fixed therebetween. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com