Intake air cooling diffusion diversion device for direct air-cooled condenser

A technology of air-cooled condenser and diversion device, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of poor thermal economy, increased cooling air inlet temperature, and increased back pressure of steam turbine units. , to achieve the effect of improving thermal economy, improving heat exchange efficiency, and reducing inlet air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

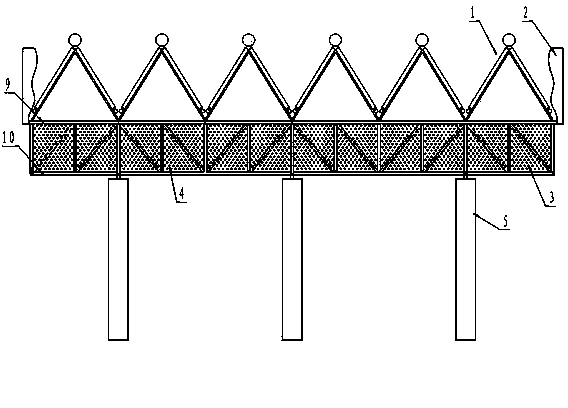

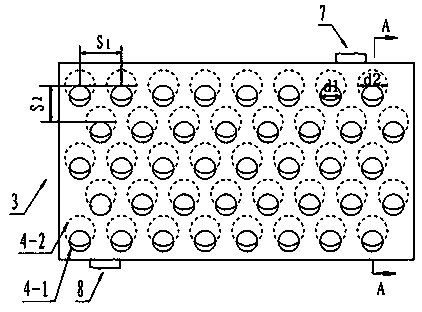

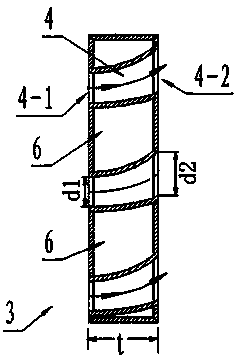

[0026] see figure 1 , the present invention comprises a steel frame 10, the lower part of the steel frame is supported on the ground by support columns 5, the upper part of the steel frame is provided with an air-cooling platform 9, and a plurality of air-cooling units 1 are arranged on the air-cooling platform, each air-cooling unit is provided with a fan, and the surrounding air-cooling platform There is a windshield 2. In order to effectively weaken or eliminate the influence of ambient wind on the direct air-cooled condenser, and improve the heat exchange efficiency of the air-cooled condenser under strong wind or high temperature conditions, the device of the present invention is provided with a plurality of interconnected cooling diffuser guide boxes 3. Each cooling diffuser and guide box is fixed on the steel frame and covered with the steel frame, and the cooling diffuser guide box is evenly distributed with transparent air ducts 4 . The advantage of installing the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com