Uniform temperature plate and manufacturing method thereof

A technology of vapor chamber and side plate, which is applied in the direction of manufacturing tools, cooling/ventilation/heating transformation, lighting and heating equipment, etc., which can solve the problem of dirty working environment of the production line, easy peeling of solder, and unevenness of the periphery of the vapor chamber Status and other issues, to achieve the effect of keeping the working environment clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The detailed description and technical content of the present invention will be described as follows with reference to the accompanying drawings, but the accompanying drawings are for illustrative purposes only and are not intended to limit the present invention.

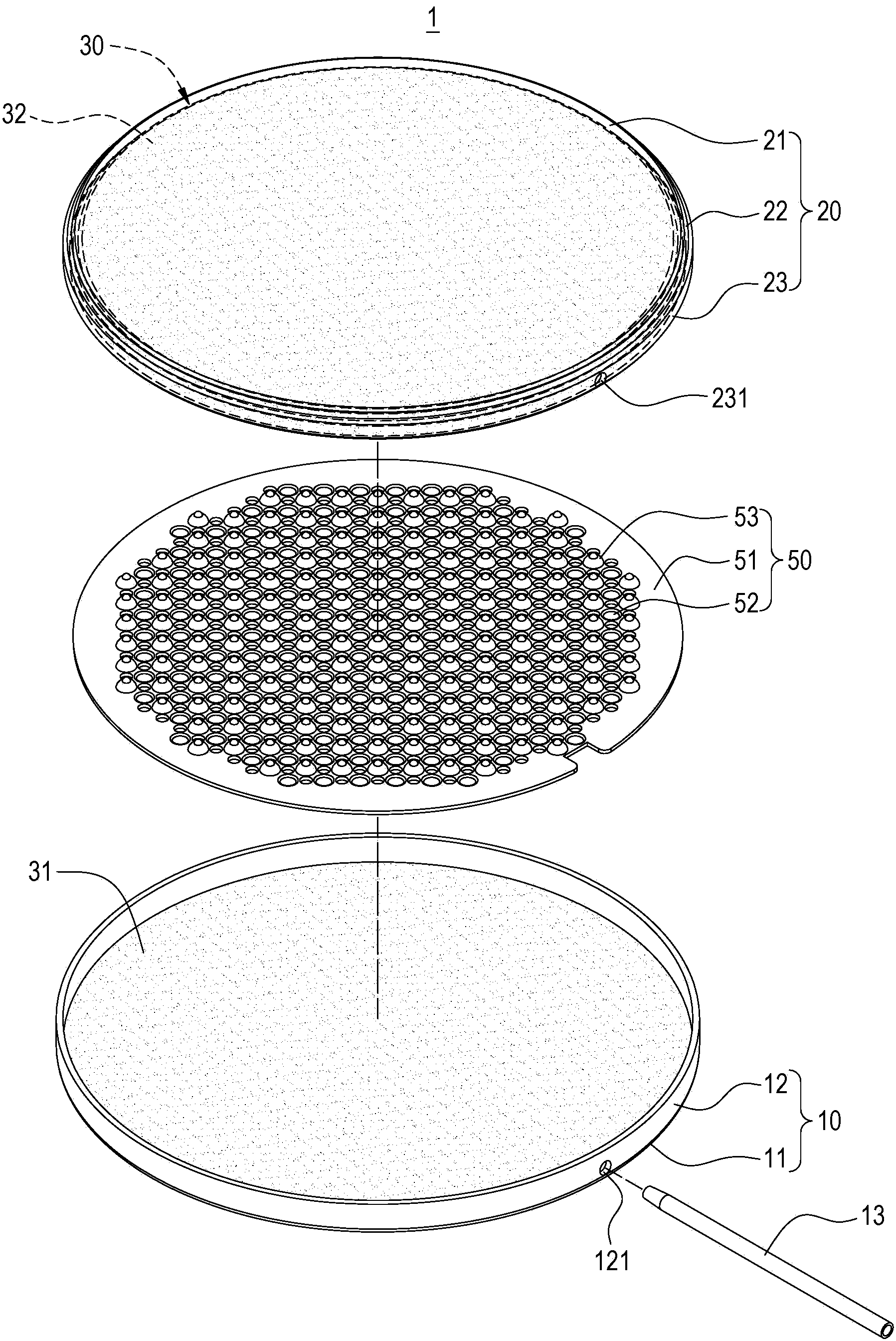

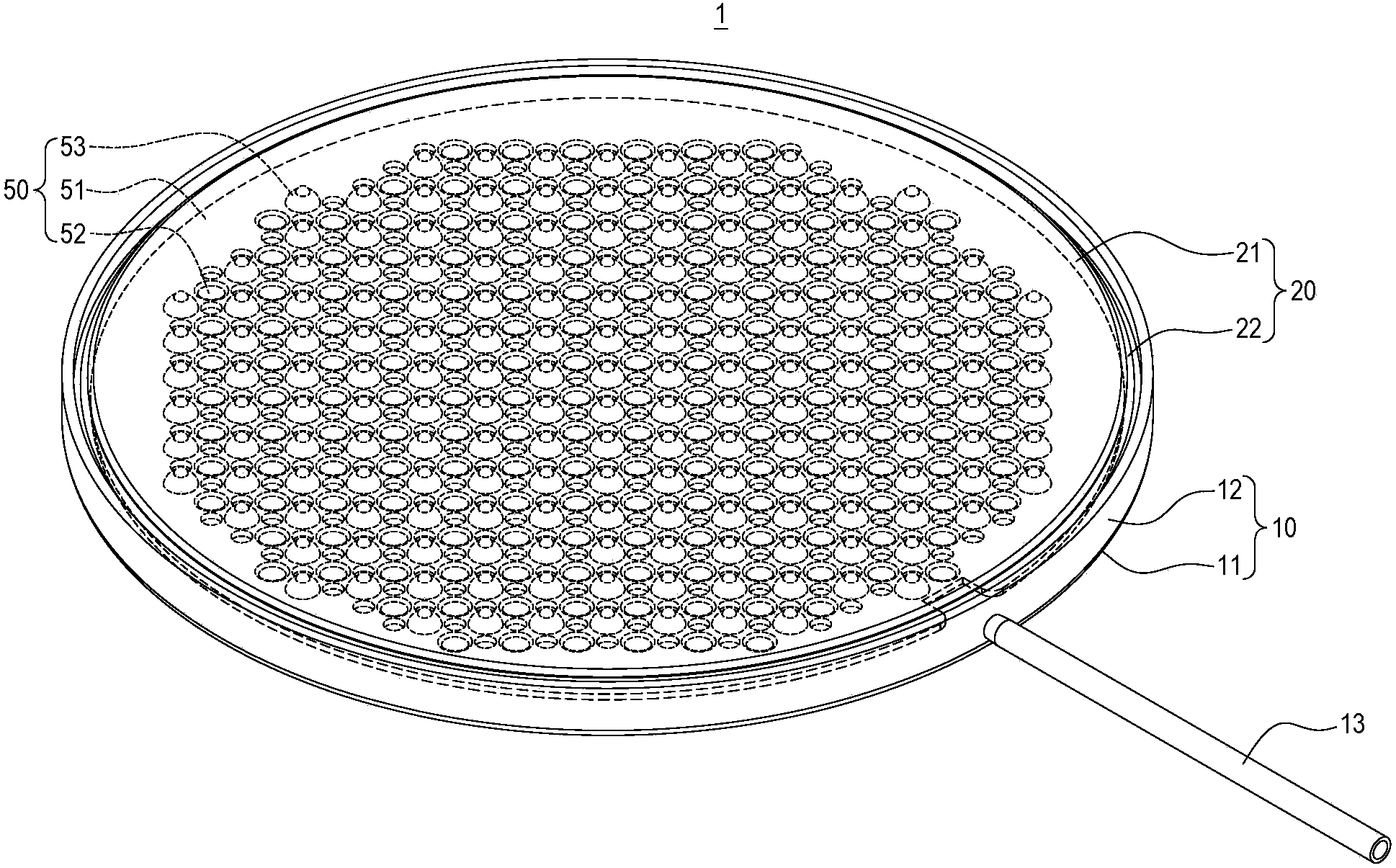

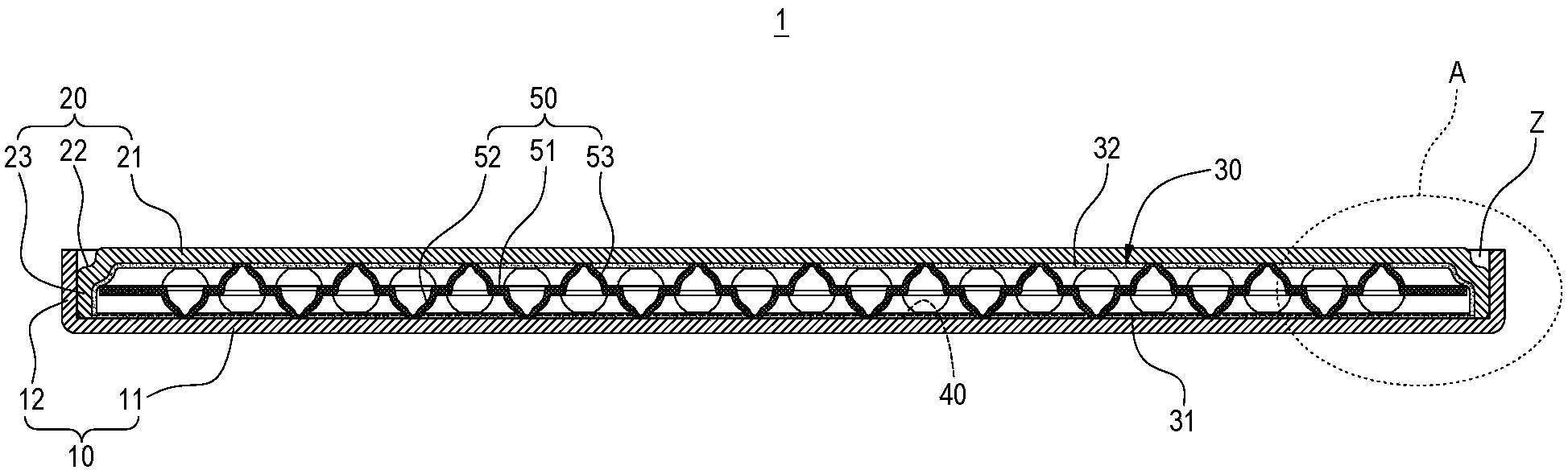

[0050] Please refer to Figure 1 to Figure 5 , The invention provides a vapor chamber and a manufacturing method thereof. The vapor chamber 1 of the present invention includes: a lower casing 10 , an upper casing 20 , a capillary structure 30 , a working fluid 40 , and a supporting structure 50 .

[0051] The lower casing 10 is roughly disc-shaped and can be made of metal or ceramic material. The lower casing 10 is made to have a bottom plate 11 and a lower side plate 12 extending on the periphery of the bottom plate 11. The lower side plate 12 has a divider. The air hole 121 is used for a degassing pipe 13 to pass through. In addition, a lower capillary portion 31 is sintered on the upward facing surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com