The instrument placement platform fixed in the automobile inspection workshop with spiral lift

A technology of spiral lifting and placing the platform, applied in the direction of measuring instrument components, instruments, measuring devices, etc., can solve the problems of difficult to adjust the height of the platform, disordered cables, easy to be damaged, etc., to maintain vertical, conducive to maintenance, Guaranteed safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

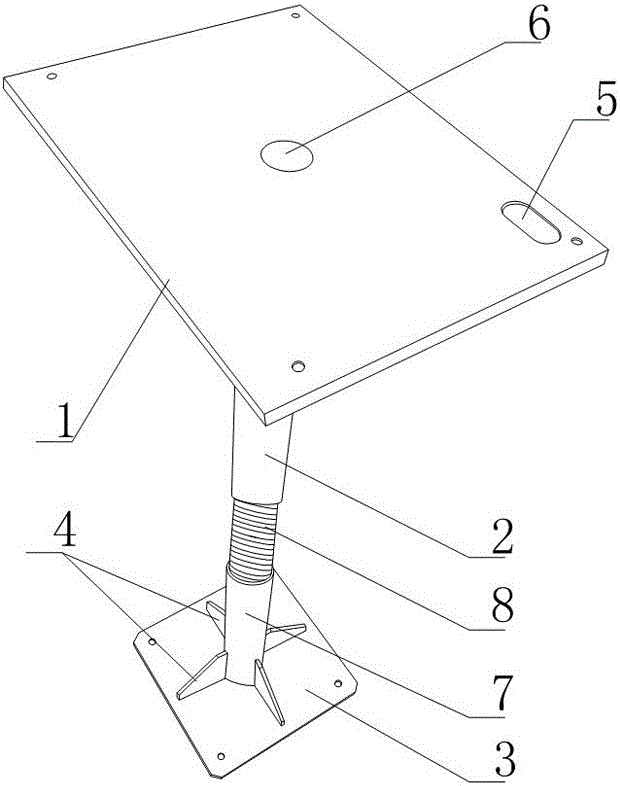

[0019] Such as figure 1 As shown, the present invention is fixed on the instrument placement platform of the automobile inspection workshop in a spiral lift type, and the connecting plate 3 and the flat plate 1 are parallel to each other, wherein the connecting plate 3 is rectangular in shape as a whole, and is used to be installed on the ground to increase the contact area between the whole and the ground. To reduce the pressure on the ground, the plate 1 is also rectangular as a whole, and its area is much larger than that of the connecting plate 3. It is used to install the display screen of the test instrument. There is a lower column 7, the lower column 7 is a cavity structure, and the upper column 2 is provided with a connecting rod 8 that matches the inner cavity of the lower column 7. The connecting rod 8 is cylindrical as a whole, and its outer diameter is the same as that of the lower column 7. The inner cavity is matched, and its interior is a cavity structure. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com