In situ observation experiment apparatus for electrochemical corrosion measurement

An experimental device and electrochemical technology, applied in the field of in-situ observation experimental devices for electrochemical corrosion measurement, can solve the problems of inability to observe the surface changes of metal materials, and achieve the effect of easy replacement and scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

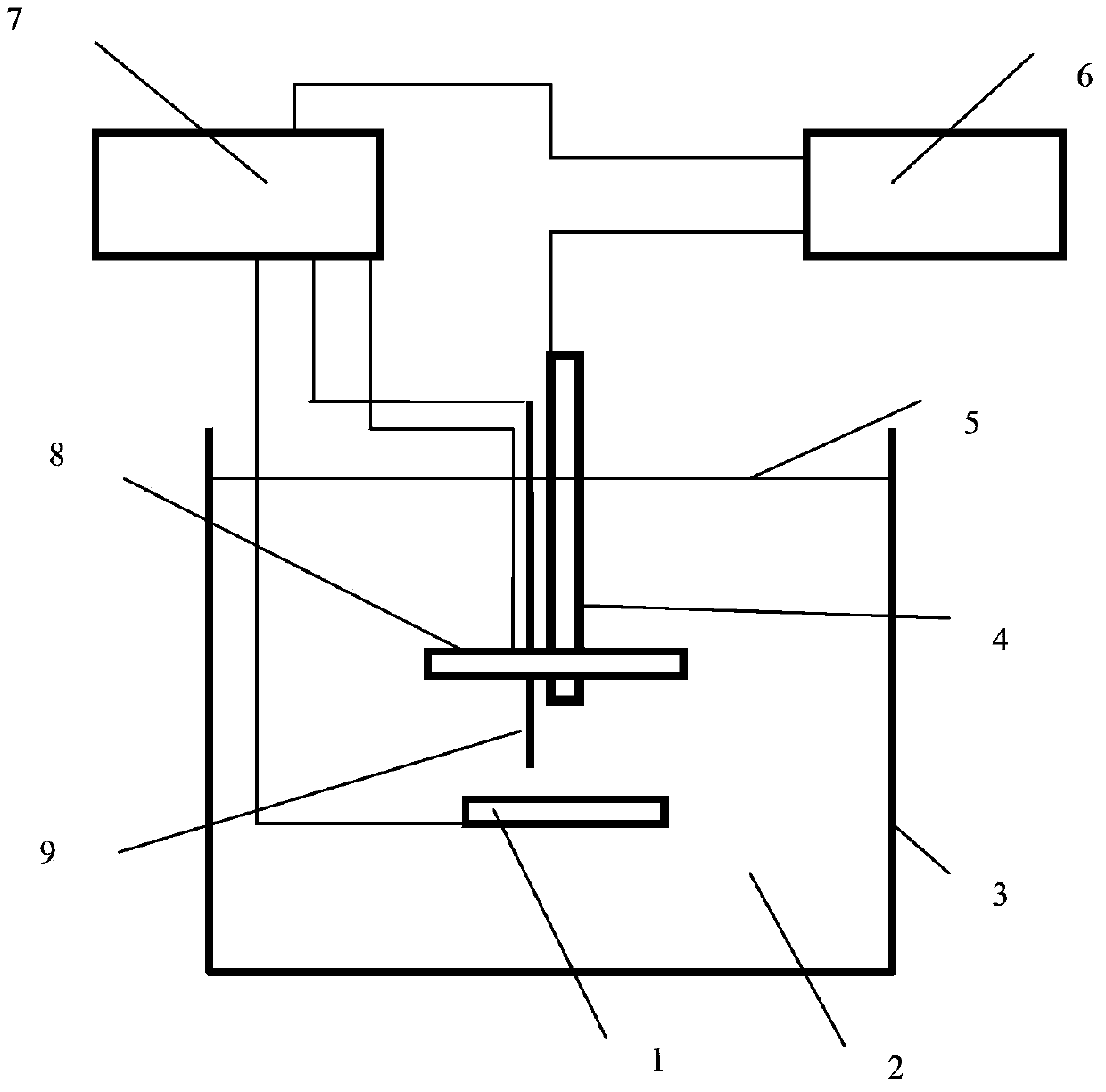

[0022] like figure 1 As shown, the electrochemical corrosion measurement in-situ observation experimental device of the present invention mainly includes: metal sample 1, transparent corrosive liquid 2, container 3, miniature digital microscope (300 times) 4, corrosive liquid surface 5, computer 6, electrochemical Workstation 7, auxiliary electrode 8, reference electrode 9, etc. The specific structures are as follows:

[0023] The container 3 is filled with a transparent corrosive liquid 2, the metal sample 1, the computer 6, the auxiliary electrode 8, and the reference electrode 9 are connected to the electrochemical workstation 7 through wires, and a miniature digital microscope (300 times) One end of the digital microscope 4 extends into the transparent corrosive liquid 2 under the corrosive liquid surface 5 , and corresponds to the metal sample 1 .

[0024] In the present invention, the micro digital microscope is provided with a liquid-proof cover at the part inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com