A polycrystalline silicon resistor and a manufacturing method thereof

A technology of polysilicon resistors and polysilicon, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of local field oxide layer 103 breakdown, polysilicon resistors cannot reach high voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

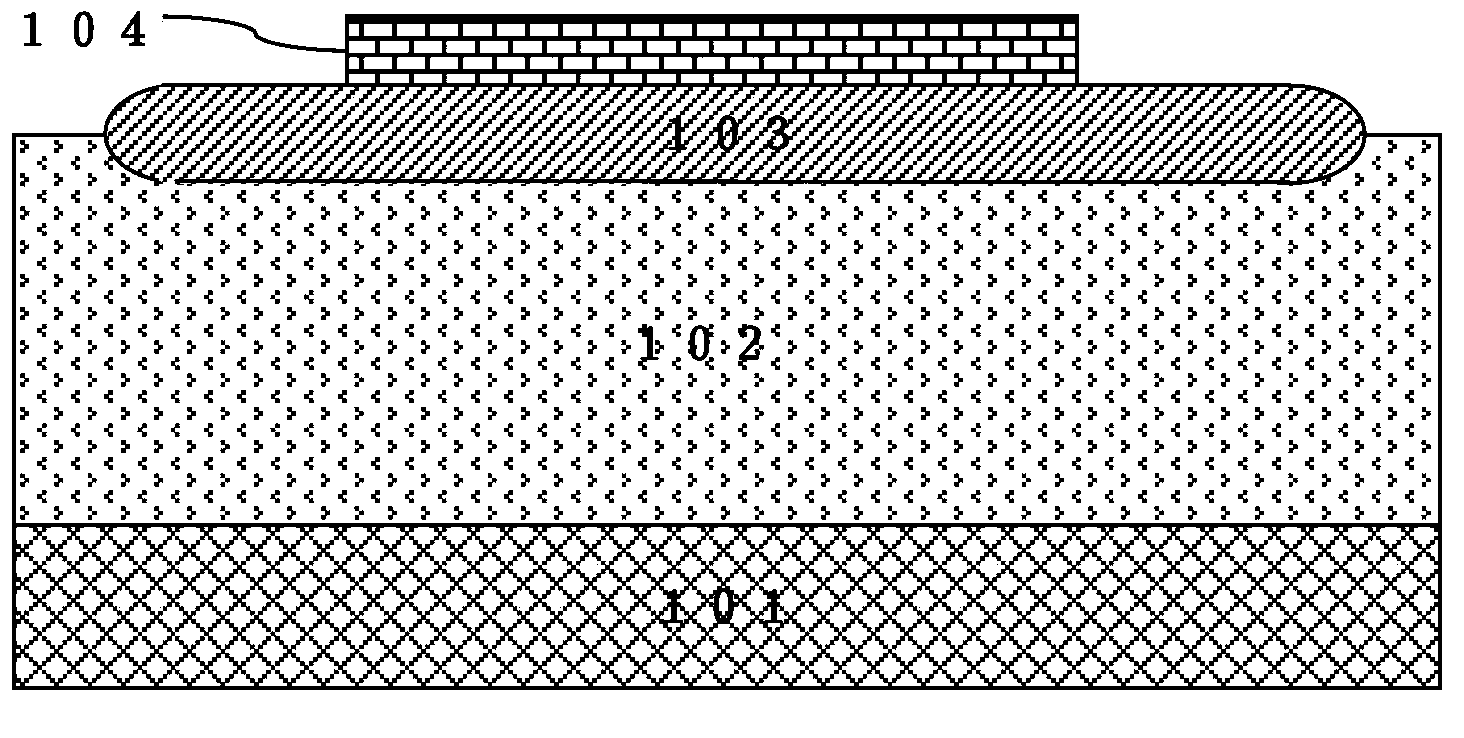

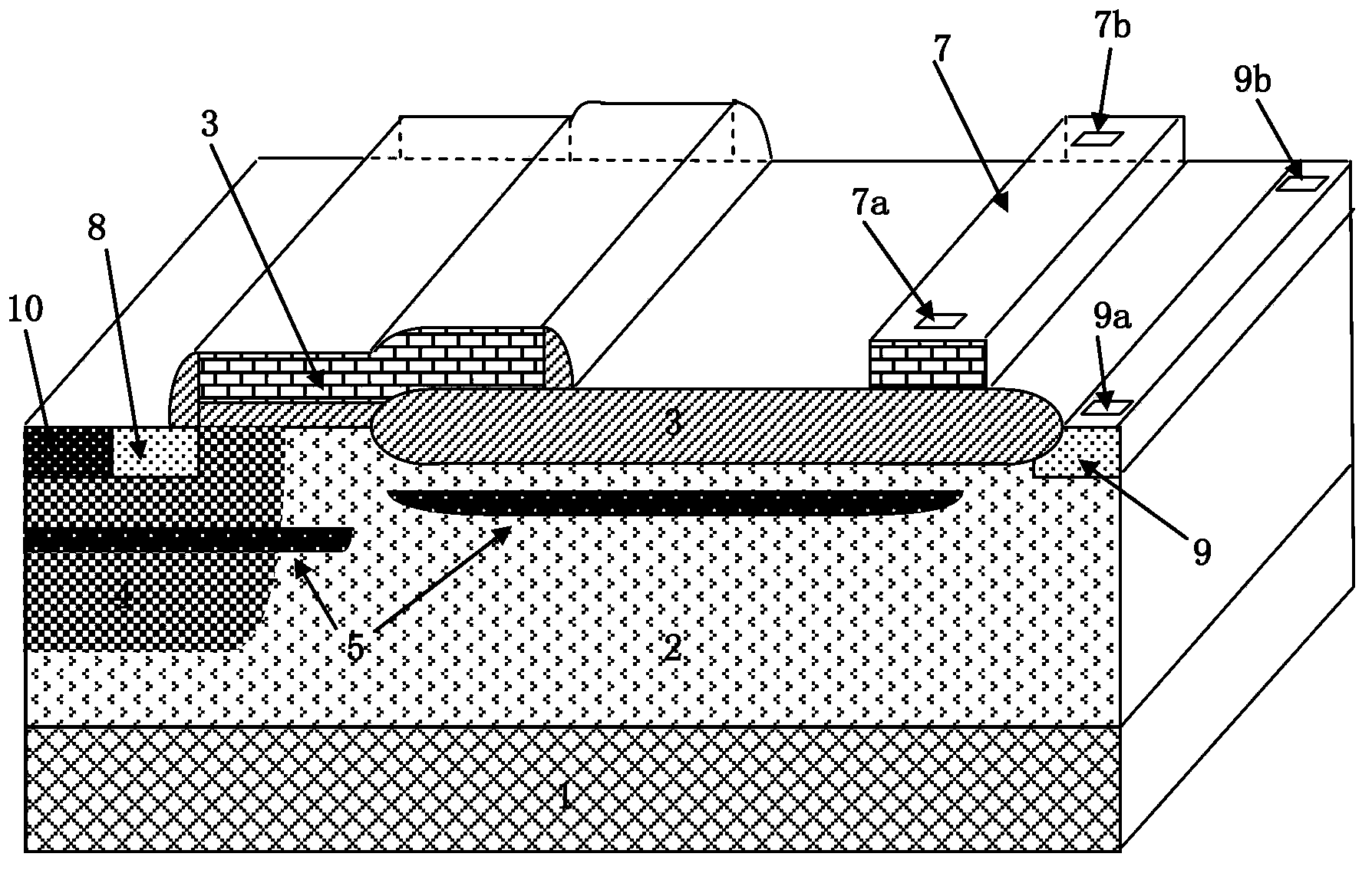

[0043] Such as figure 2 Shown is a schematic structural diagram of a polysilicon resistor according to an embodiment of the present invention. The polysilicon resistor of the embodiment of the present invention, the LDMOS device used in the polysilicon resistor of the embodiment of the present invention is described by taking an N-type LDMOS device as an example. The polysilicon resistor of the embodiment of the present invention includes:

[0044] A P-type silicon substrate 1, an N-type well region 2 is formed on the silicon substrate 1, and a field oxide layer 3 is also formed on the silicon substrate 1. The N-type well region 2 is formed by ion implantation and high-temperature push well before the formation of the field oxide layer 3. The implanted impurity of the ion implantation in the N-type well region 2 is phosphorus, and the implantation energy is 100keV-300keV. dose of 10 11 cm -2 ~10 14 cm -2 , the temperature of the high-temperature push well in the N-type w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com