Method for cutting and separating plate glass

A flat glass and separation method technology, which is applied to glass cutting devices, glass manufacturing equipment, electrical components, etc., can solve the problems of scratches, cracks, and quality reduction of flat glass on the cutting surface, so as to eliminate important factors, quality reduction, Anti-abrasion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

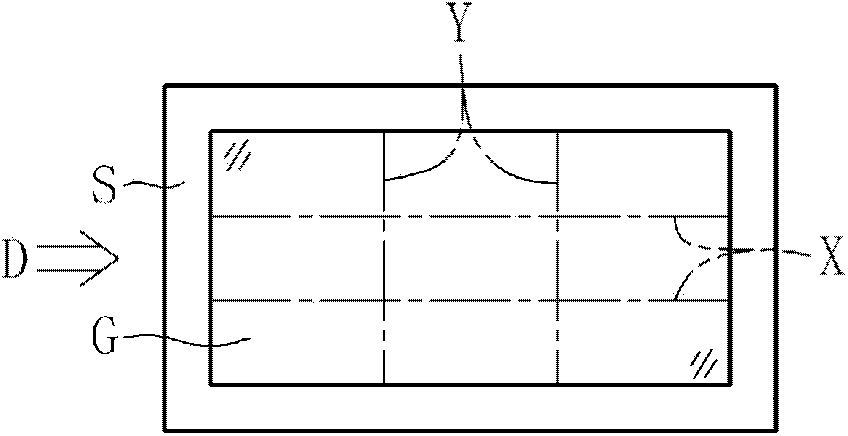

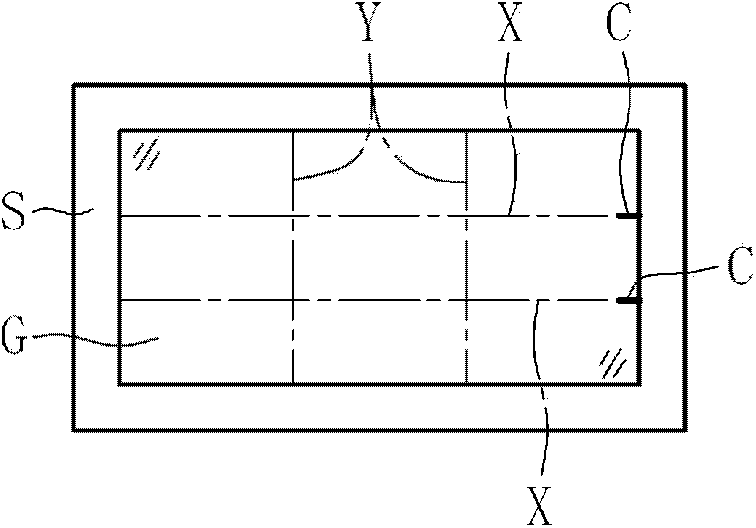

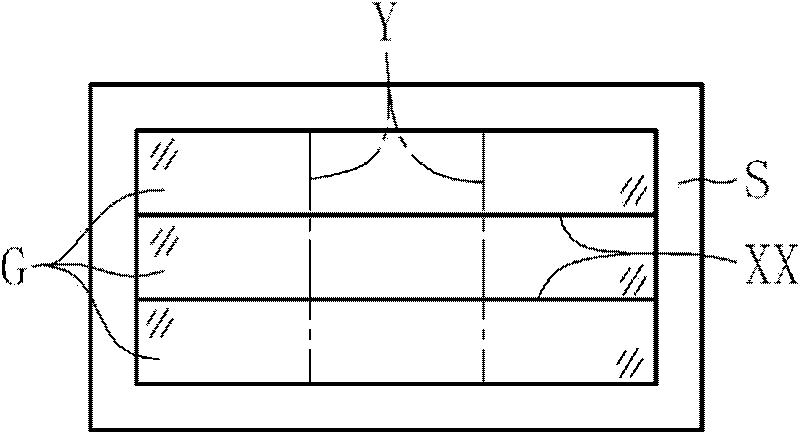

[0040] Below, based on the attached Figure 1a ~ Figure 1h , Figure 2a ~ Figure 2d The method of cutting and separating sheet glass according to the embodiment of the present invention will be described.

[0041] As the cutting and separating method of flat glass according to the first embodiment of the present invention, such as Figure 1a ~ Figure 1h As shown, a description will be given of the case where the plate glass G is cut into nine rectangular plate glasses G by laser cutting, and the cut plate glasses G are separated from each other, and those that cannot be used as products are discarded. part. It should be noted, Figure 1a ~ Figure 1g is a top view, Figure 1h From Figure 1a A side view viewed in the direction of arrow D shown.

[0042] Such as Figure 1a As shown, in 1st Embodiment, the sheet glass G cut|disconnected by the laser cutting method is mounted on the sheet|seat S (henceforth only referred to as the sheet|seat S) which has stretchability. As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com