Rotating-platform vacuum filtering machine and filtering method

A technology of a vacuum filter and a filtration method, applied in the field of filtration, can solve the problems of affecting ferrous sulfate, low filtration effect, unstable titanium dioxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

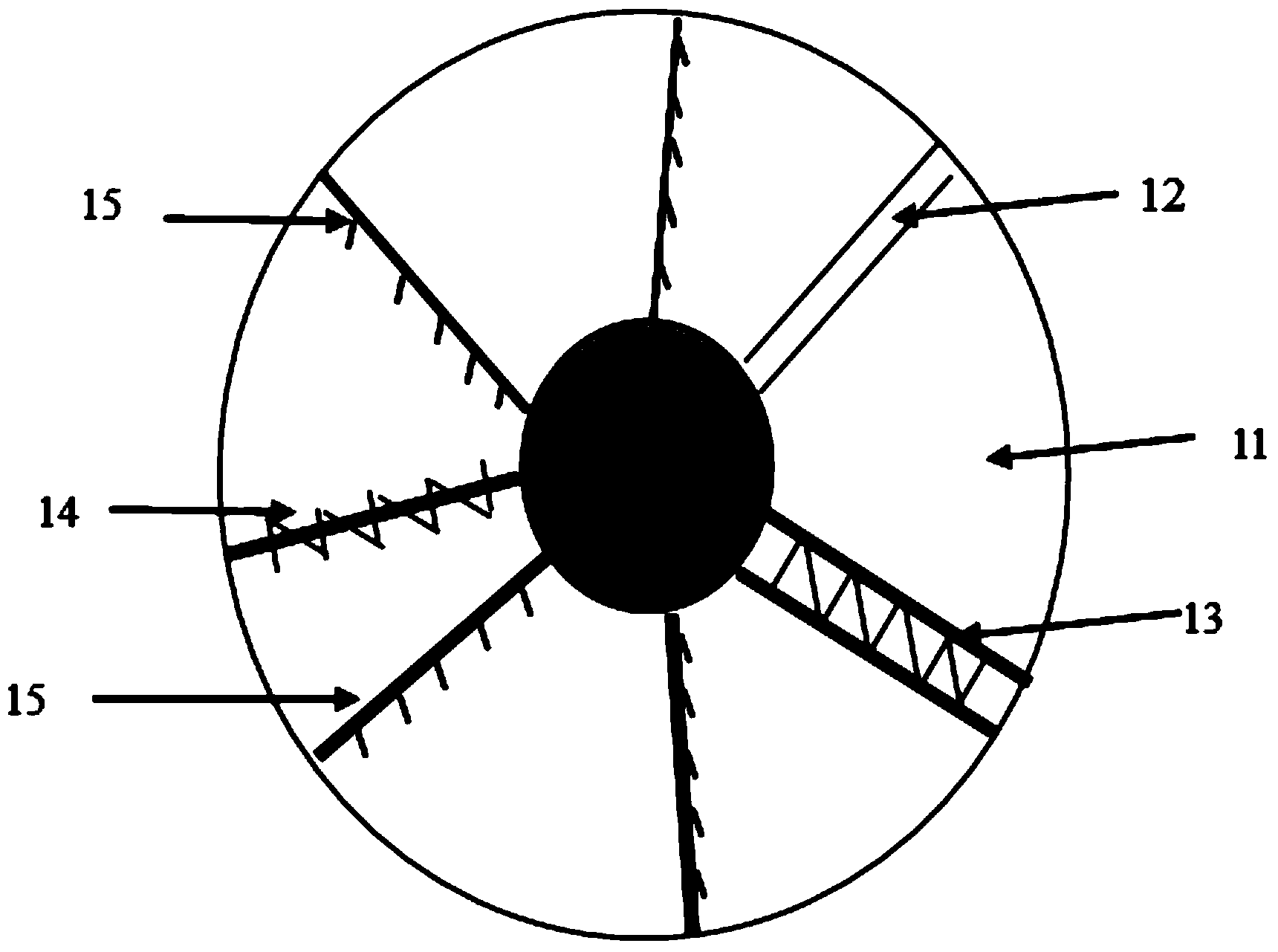

[0059] The rated feed rate in the prior art is 50m 3 The rotary table vacuum filter (manufactured by Jiangsu Xinhongda, HDZP-T30-00) is optimized for the rotary table vacuum filter of the present invention, with two scrapers added, the first scraper is set at the feed inlet and the outlet Between the feeding augers, 1 / 3 of the distance from the feed inlet; the second scraper is set between the feed inlet and the discharge auger, 2 / 3 of the distance from the feed inlet. Add 4 spray pipes, the first spray pipe is set between the feed inlet and the first scraper; the second spray pipe is set between the first scraper and the second scraper, the distance from the first The position of 1 / 3 of the first scraper; the third spray pipe is set between the first scraper and the second scraper, 2 / 3 of the distance from the first scraper; the fourth spray pipe Set between the second scraper and the discharge screw.

[0060] Open the filter disc, and the titanium liquid mixed slurry conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com