Four-column oil-pressure square pipe punching equipment

A punching and hydraulic technology, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of inability to meet the needs of personalized profile processing and low efficiency, and achieve the effect of simple structure and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

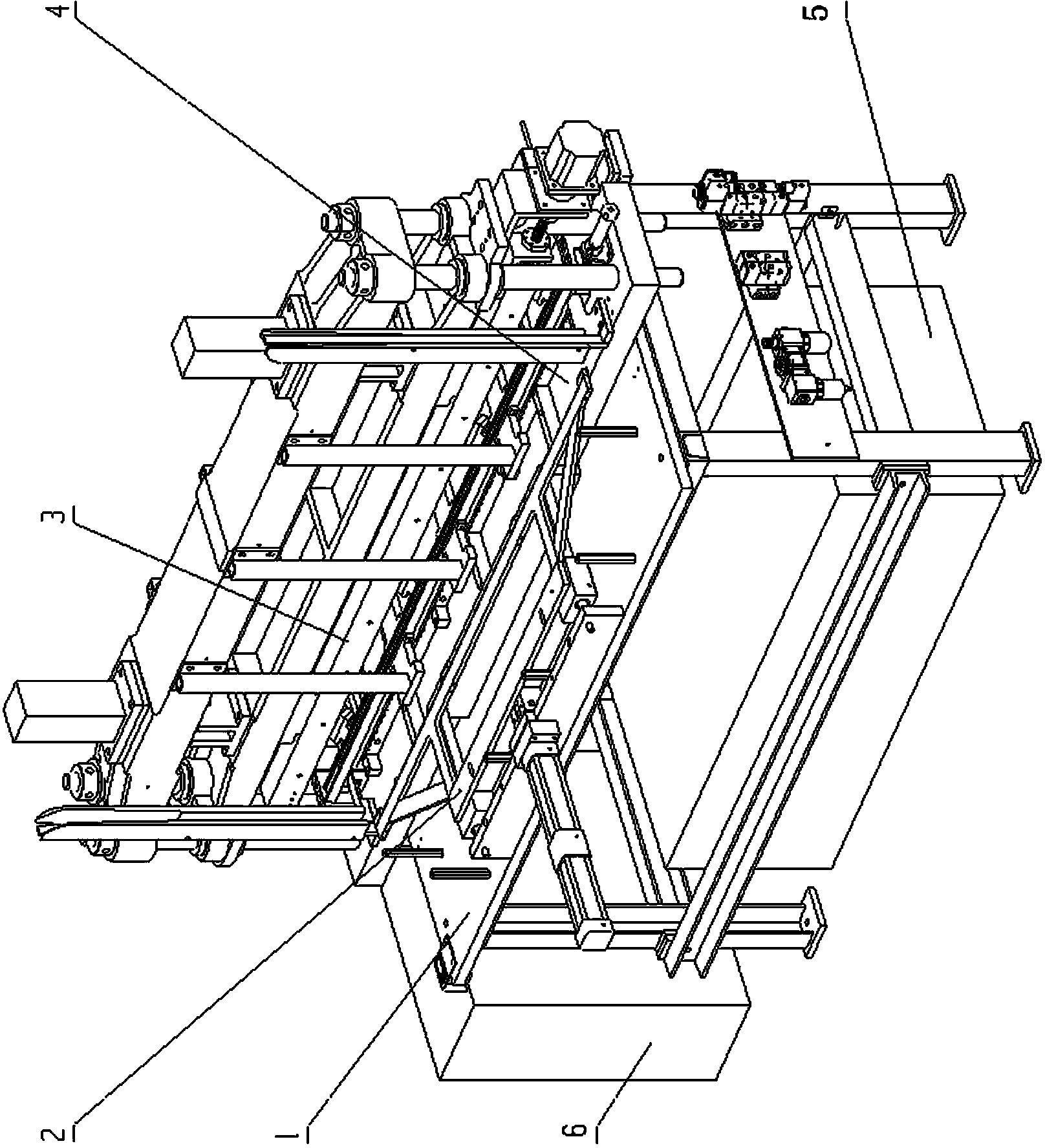

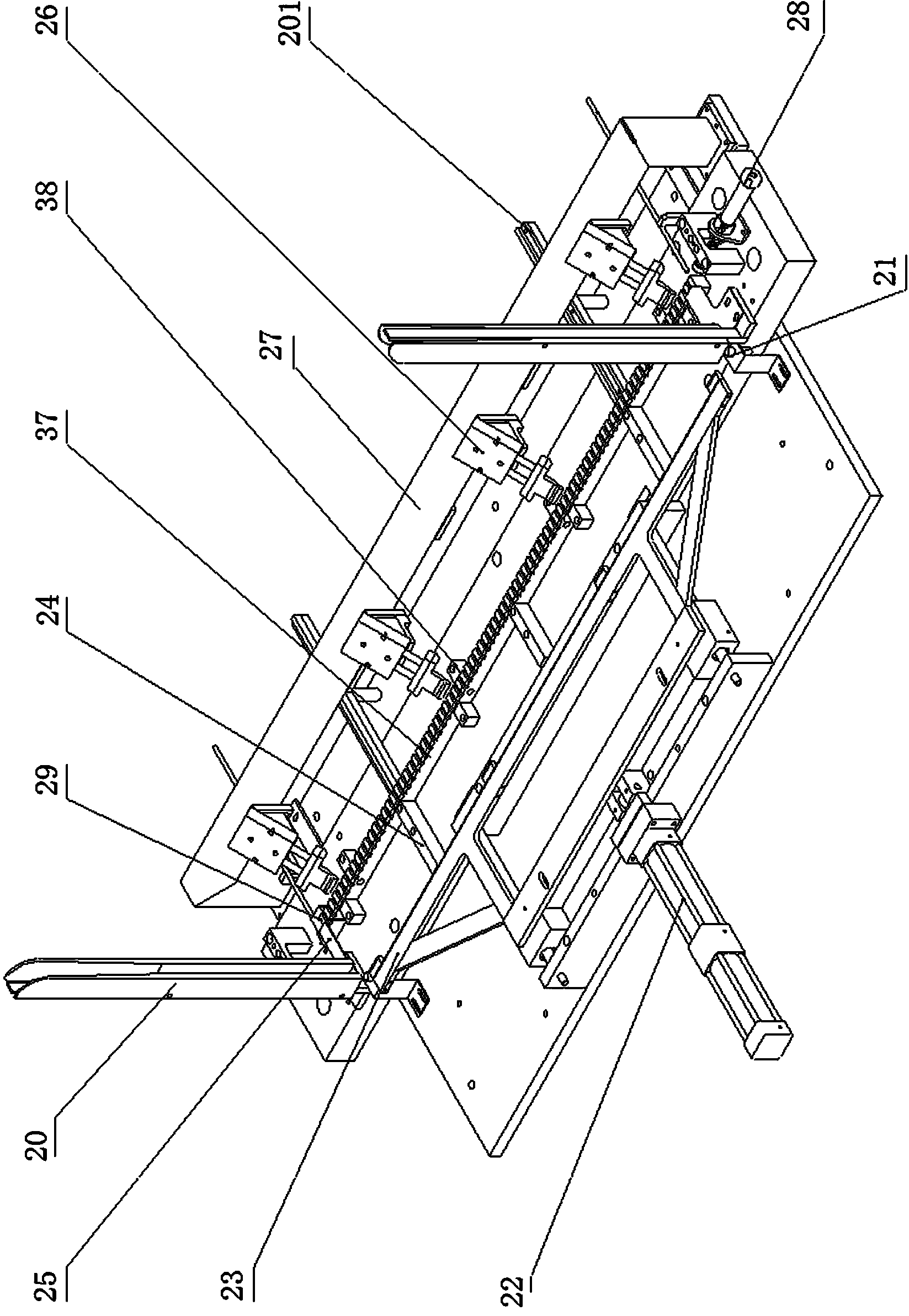

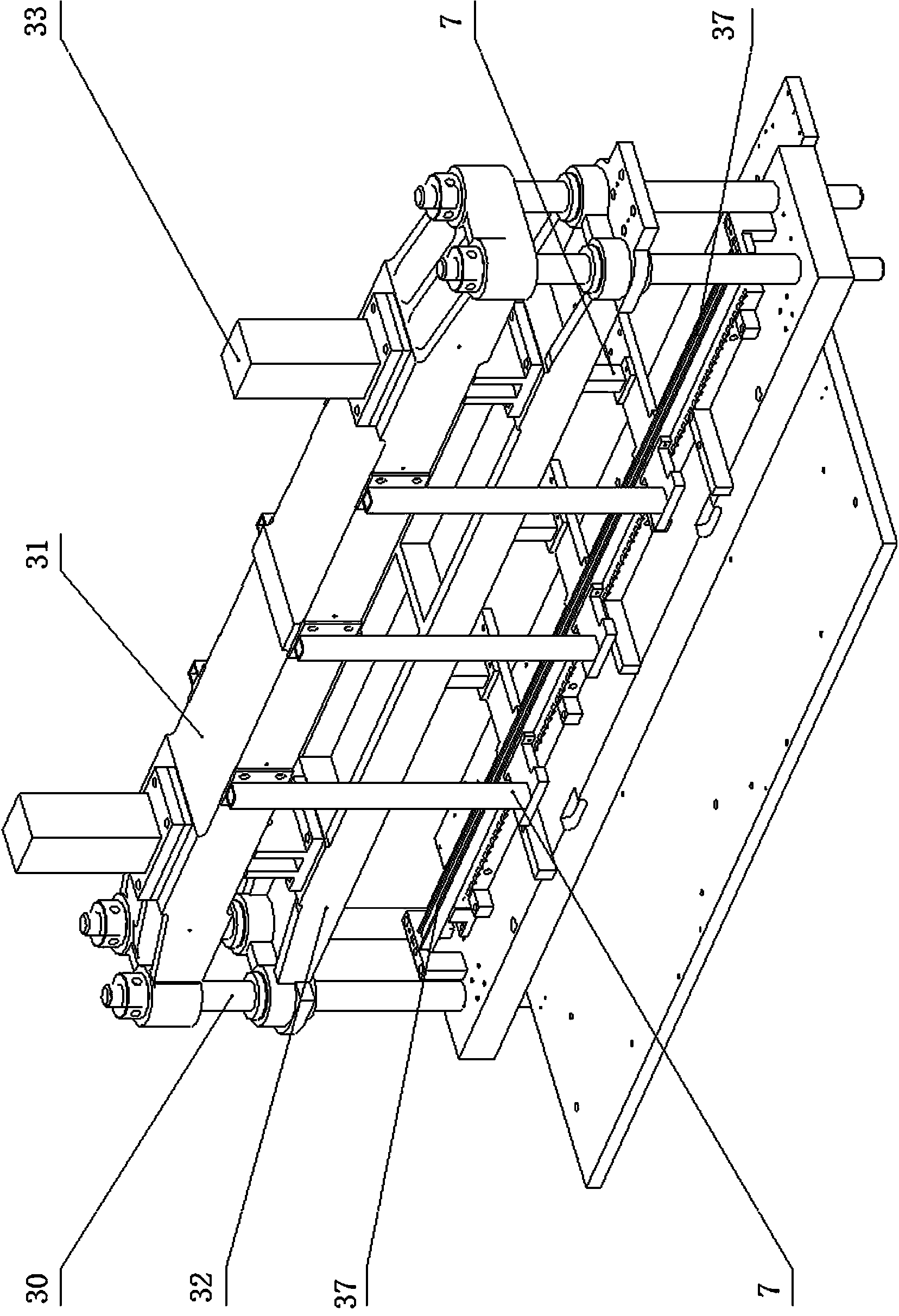

[0033] The working principle of a four-column hydraulic square tube punching equipment: including a frame 1, a feeding and discharging device 2, a punching device 3, a punching workbench 4, a hydraulic power device 5, and a PLC electric cabinet 6, wherein the hydraulic power device 5 Provide power, PLC electric cabinet 6 controls the process of processing, the frame 1 is placed at the bottom of the equipment, the feeding and discharging device 2 is placed on the frame 1, the punching table 4 is fixedly connected to the frame 1, and the punching table 4 is installed Below the feeding and discharging device 2 and above the punching table 4 is a punching device 3 . Through the control of PLC, the hydraulic and pneumatic actuator completes feeding, positioning, stepping punching, and discharging, and realizes the punching work of the opposite pipe. The oil pressure is supplied by the hydraulic power unit 5 placed under the frame 1, and the pneumatic actuator is controlled by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com