Roller out-of-order roughening processing method based on fiber laser

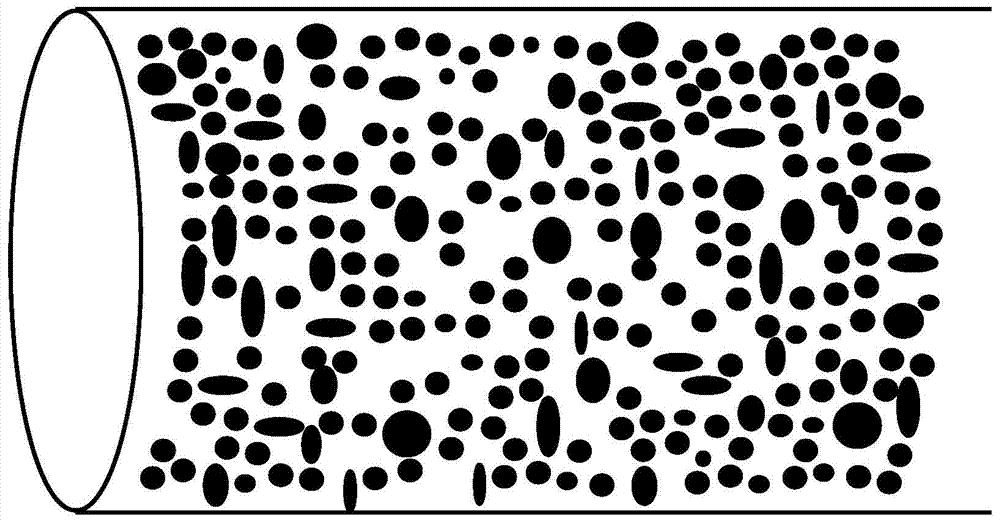

A technology of fiber laser and processing method, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of steel plate deep drawing performance influence, complicated control equipment, and irregular roughened point appearance, etc., and achieves improved surface Appearance quality and service life, improved wear resistance and service life, uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

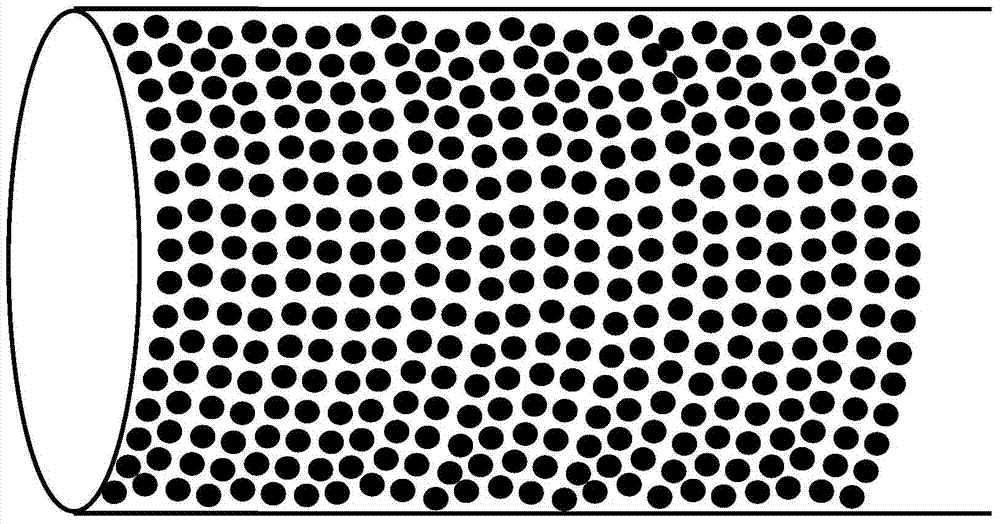

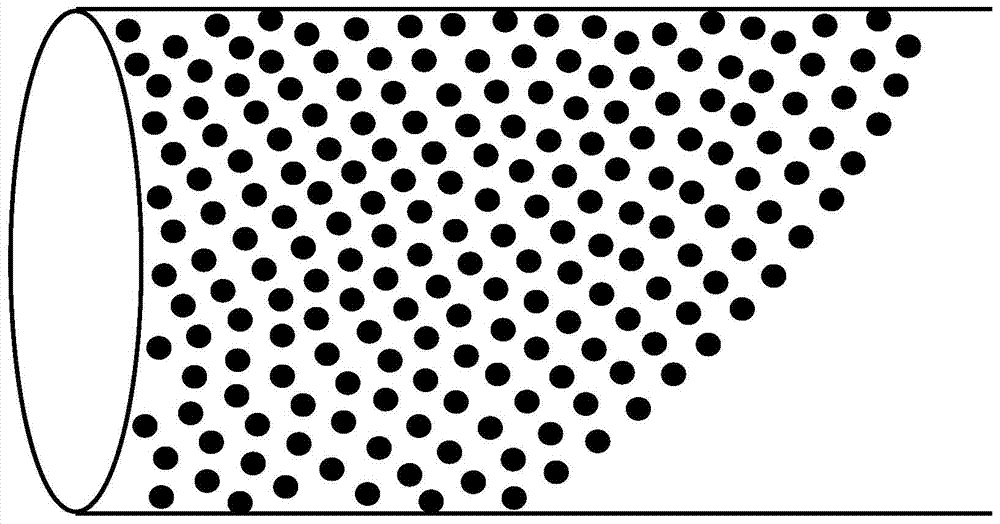

[0037] The processed roll 3 is placed on the roll shaft 4 of the CNC machine tool 2, and is tightened by the top 5; the CNC machine tool 2 is started to make the processed roll 3 rotate around its axis; at the same time, the driving mechanism in the CNC machine tool 2 Control the texturing platform 7 on the translation guide rail 6 to move parallel to the axial direction of the processed roll 3; drive the laser focusing head 8 located on the texturing platform to move back and forth along the axial direction of the processed roll 3. The laser focusing head 8 receives the pulsed laser light emitted by the laser 1, and sends a pulsed laser beam to the processed roll 3 at regular intervals. The staggered array of high-density and uniform small micro-pit lattices formed by the short-range helix δ of the inclination angle, thereby performing texturing processing on the processed roll 3 .

[0038] In this embodiment, the material of the processed roll 3 is 9Cr3Mo, its diameter d=60m...

Embodiment 2

[0043] Embodiment 2 is basically the same as Embodiment 1, except that the material of processed roll 3 in Embodiment 2 is 9Cr2W, its diameter d=50mm, and its total length is 4000mm; the wavelength of fiber pulse laser is 1.6μm, the frequency is 3000Hz, and the conversion period t is 10s, and the length of the helix δ is 500mm. Table 2 shows the rotational speed ω of part of the processed roll 3 and the traverse speed v of the laser focusing head 8 along the axial direction of the processed roll 3 .

[0044] Table 2

[0045] ω (rpm)

[0046] The shape of the textured lattice on the processed roll 3 treated in Example 2 is also substantially the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Transmit frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap