Control mechanism for index plunger

A technology of control mechanism and indexing pin, which is applied in the field of workpiece positioning device, to achieve the effect of avoiding improper force and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

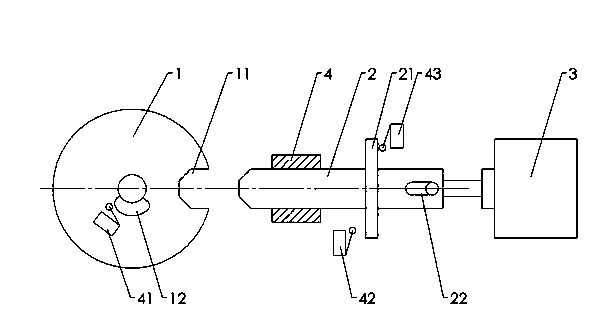

[0010] Embodiment one is basically as figure 1 As shown (part of the structure is not shown in the figure): the indexing pin is axially slidably connected in the frame, the spring connecting the indexing pin and the frame drives the indexing pin into the indexing plate, the front end of the indexing pin is in contact with the indexing The shape of the indexing hole on the dial matches, and the bar hole provided at the rear end of the indexing pin is hinged with the force-applying shaft of the solenoid valve, and the push-pull force generated by the solenoid valve drives the indexing pin to move axially.

[0011] The main shaft of the indexing plate is fixedly welded with a cam, and the middle part of the indexing pin is welded with a ring-shaped convex edge. When the indexing pin is inserted into the indexing hole, the indexing axis advance limit switch is closed, and when the indexing pin exits the indexing hole, the indexing shaft retreats. The limit switch is closed. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com