Oil pump shaft detecting and positioning mechanism

A technology of positioning mechanism and oil pump shaft, which is applied in the direction of measuring device, instrument, workpiece clamping device, etc., and can solve the problem of inability to detect the oil pump shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

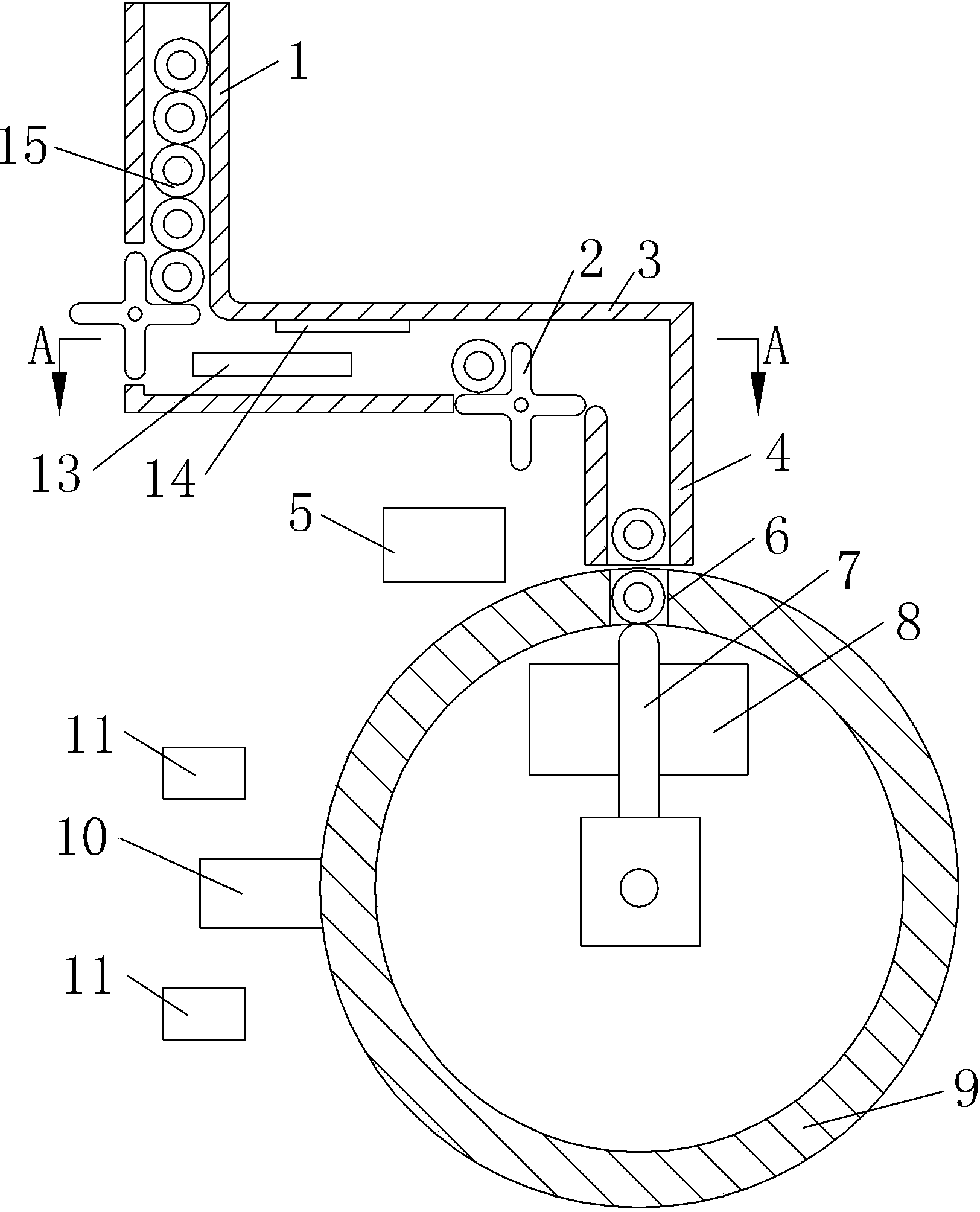

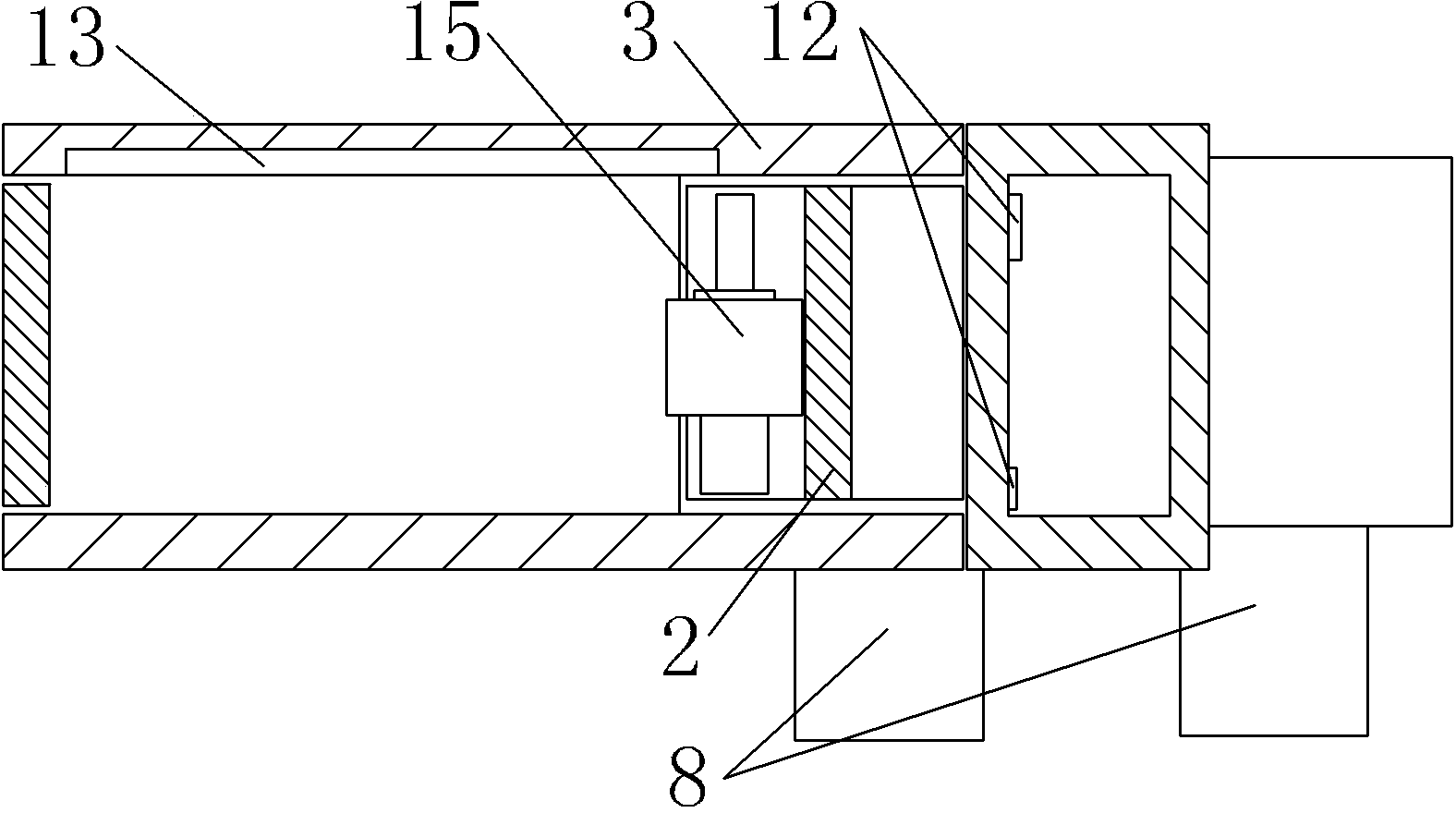

[0009] The reference signs in the drawings of the specification include: input chute 1, cross-shaped stopper 2, detection pipe 3, feed pipe 4, waste chute 5, notch 6, support pin 7, output chute 8, positioning drum 9. Control handle 10, solenoid valve 11, orientation detector 12, cylindricity detector 13, shaft runout detector 14, oil pump shaft 15.

[0010] Below in conjunction with accompanying drawing and embodiment technical solution of the present invention is described in further detail:

[0011] For the convenience of description, the "Up", "Down", "Left" and "Right" referred to below are respectively related to the attached figure 1 The up, down, left and right directions are the same, but it does not limit the structure of the present invention.

[0012] Such as figure 1 and figure 2 As shown, the oil pump shaft detection and positioning mechanism of an embodiment of the present invention includes an input chute 1, an output chute 8, a solenoid valve 11, a detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com