Method for manufacturing can cap easy to remove

A manufacturing method and technology of bottle caps, applied in the directions of closure, packaging, transportation and packaging, etc., can solve problems such as accidental injury accidents, laborious opening of bottle caps, etc., and achieve the effects of reducing difficulty, saving production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

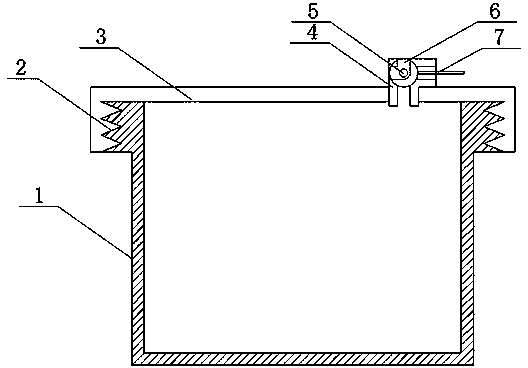

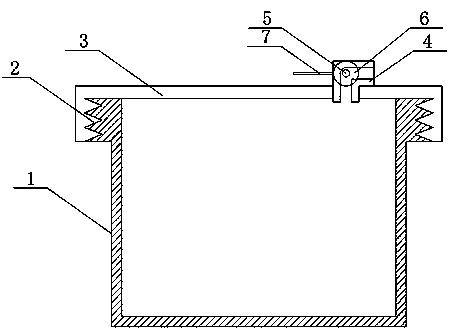

[0020] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the use status diagram of the present invention.

[0021] A kind of manufacturing method of the easy-to-open can bottle cap of the present invention, wherein, comprises the following steps: A, choose the cylindrical stainless steel bottle of height 10cm, diameter 8cm as bottle body, use milling machine at the upper end opening of bottle body, mill out screw thread tight Solid mouth, the upper end of the bottle body is provided with a bottle cap, the height of the bottle cap is 3cm, and the diameter is 8cm. The bottle cap and the bottle body are threaded at the threaded fastening port. Hole machine, drill a pressure relief valve hole with a diameter of 1.5cm, insert one end of the pressure relief valve into the bottle cap, and weld and fix it, so that the pressure relief valve is welded and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com