Precision reciprocating transfer device

A transfer device and precise technology, which can be used in conveyor objects, transportation and packaging, manipulators, etc., can solve problems such as high cost and poor accuracy, and achieve the effect of reducing accuracy requirements and reducing control difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

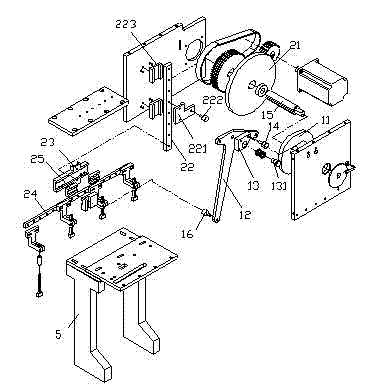

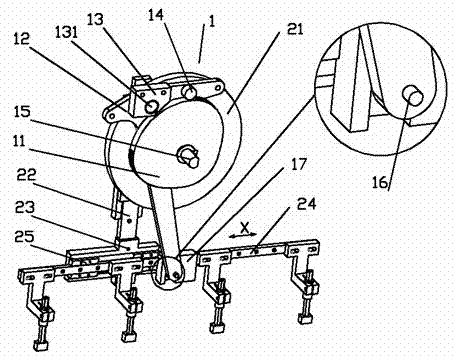

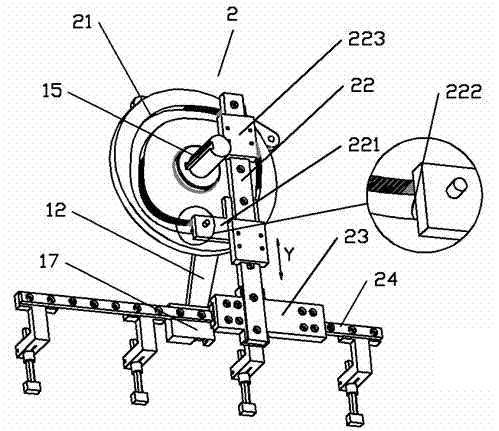

[0037] Such as Figure 1 to Figure 10 As shown, the precision reciprocating transfer device is composed of a cam swing mechanism 1, a cam lifting mechanism 2, a transmission mechanism 3, a suction nozzle member 4, a workbench 5 and a shaft frame assembly 6;

[0038] The cam rocker mechanism 1 includes a rocker cam 11, a rocker 12, a rocker fixing block 13, a rocker cam roller 14, a main shaft 15, a cross hinge cam roller 16, a cross hinge 17, and a rocker shaft 131;

[0039] The pendulum cam 11 is fixed on the main shaft 15;

[0040] The swing rod 12 is a T-shaped structure, and a fulcrum shaft hole 121 and a swing rod cam shaft hole 122 are processed on the cross arm; the fulcrum shaft hole 121 is matched with one end of the thin shaft of the swing rod rotating shaft 131;

[0041] The shaft hole is process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com