A drill rod storage mechanism

A technology of drill pipe storage and drill pipe, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., which can solve the problems of difficult installation and installation of drill pipe, high labor intensity of workers, and danger-prone, etc. The operation is difficult and labor-intensive, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A drill rod magazine mechanism provided by the present invention includes a mechanical part and a hydraulic control part;

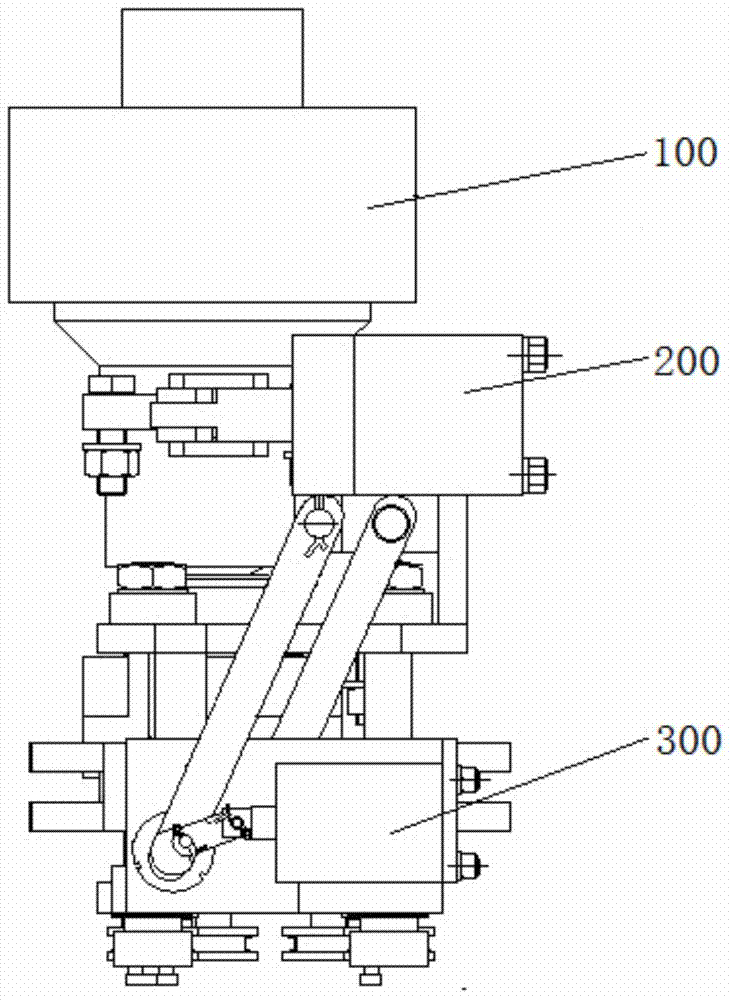

[0035] The mechanical part is composed of a rotating disk mechanism 100, a drill pipe clamping mechanism 200, and a drill pipe conveying mechanism 300; figure 1 shown.

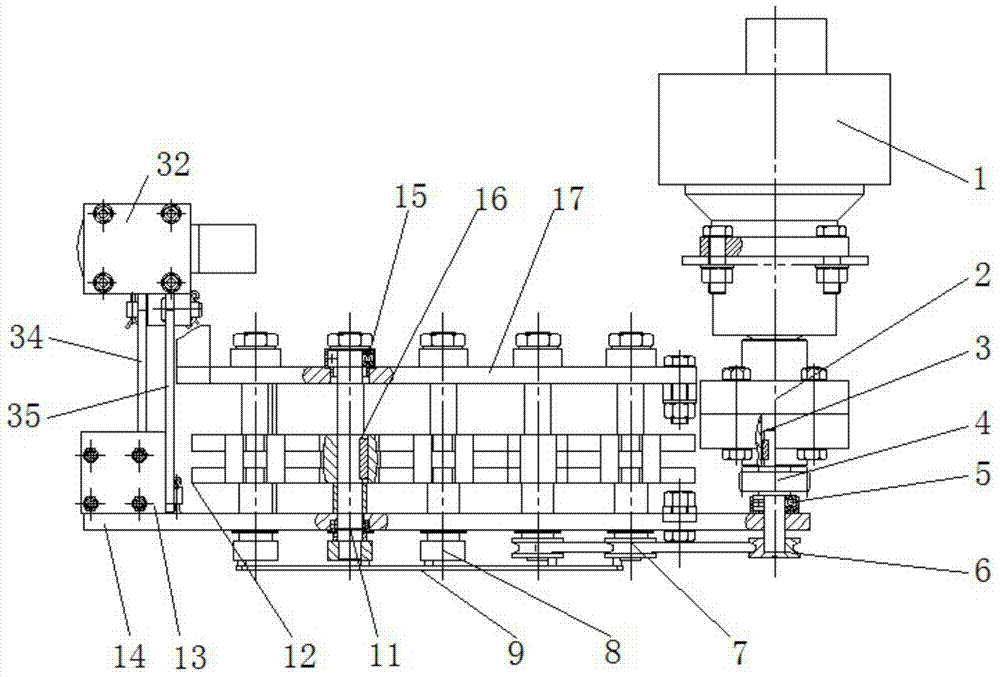

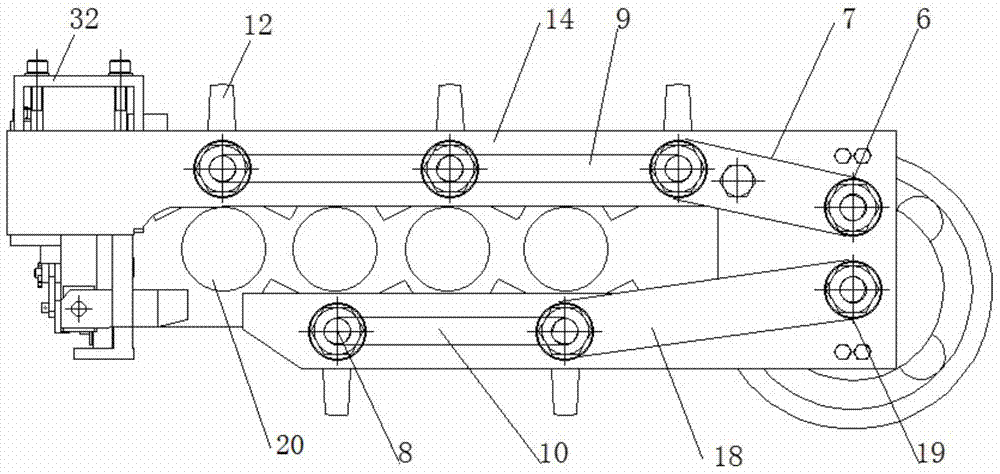

[0036] The rotary disk mechanism 100 is the core part of the design of the whole drill rod magazine. see figure 2, the rotary disc mechanism 100 is provided with a hydraulic motor 1, a shaft coupling 2, a driving gear 3, a driven gear 4, a driven shaft pulley 6, a driven pulley belt 7, a runner 8 and a runner connecting rod A9, a runner connecting rod B10, rotating shaft 11, rotating disk 12, upper support plate 17, lower support plate 14, shaft coupling 2 is installed on the main shaft of described hydraulic motor 1, coupling 2 is connected with driving gear 3, and driving gear 3 is connected with slave The driving gear 4 is meshed, and the driving gear bearing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com