Paste filling fully-mechanized coal mining device and method for support matching template

A paste filling and formwork technology, which is applied to fillings, safety devices, mine roof supports, etc., can solve the problems of low work efficiency, long labor time, and low degree of automation, and achieve low labor intensity, good safety conditions, and The effect of high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

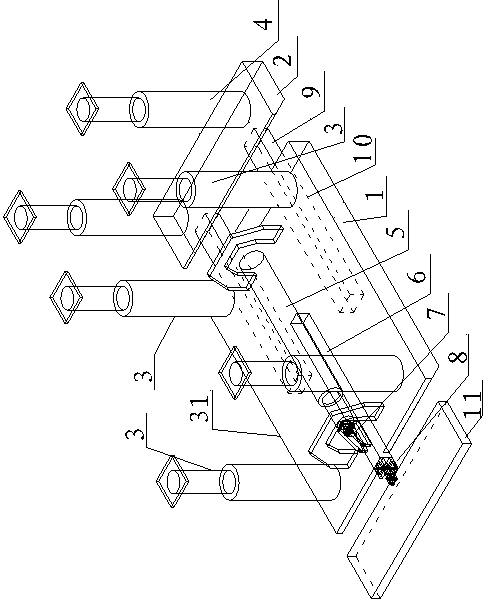

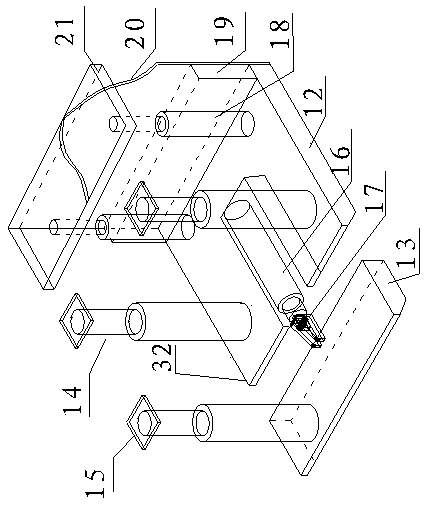

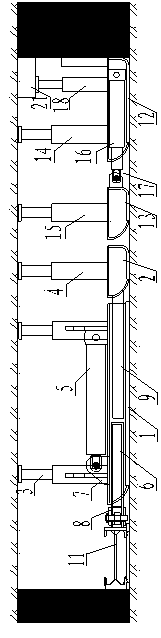

[0048] like figure 1 As shown, the device of the present invention includes a telescopic hydraulic support 31 (abbreviated as a telescopic support 31 ) and an automatic filling template 32 . The automatic filling template 32 is located behind the telescopic hydraulic support 31 .

[0049] The telescopic support 31 comprises a support main base 1 and a support sub-base 2, the support main base 1 and the support sub-base 2 are integral box structures, the main support base 1 is vertically provided with a first hydraulic prop 3, the first hydraulic prop 3 There are four, and the four are respectively located at the four corners of the main base 1 of the support, and the second hydraulic prop 4 is vertically arranged on the auxiliary base 2 of the support, and the double crossing device of the telescopic support 1 can increase the rigidity of the base.

[0050] The front middle part of the support main base 1 of the telescopic support 31 is provided with a push cylinder 5, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com