TEM sample repreparation method

A technology of sample and sample holder, which is applied in the field of TEM sample re-preparation to achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, the samples that need to be re-prepared are those that are too thick to be observed by TEM.

[0053] The specific re-preparation method is as follows:

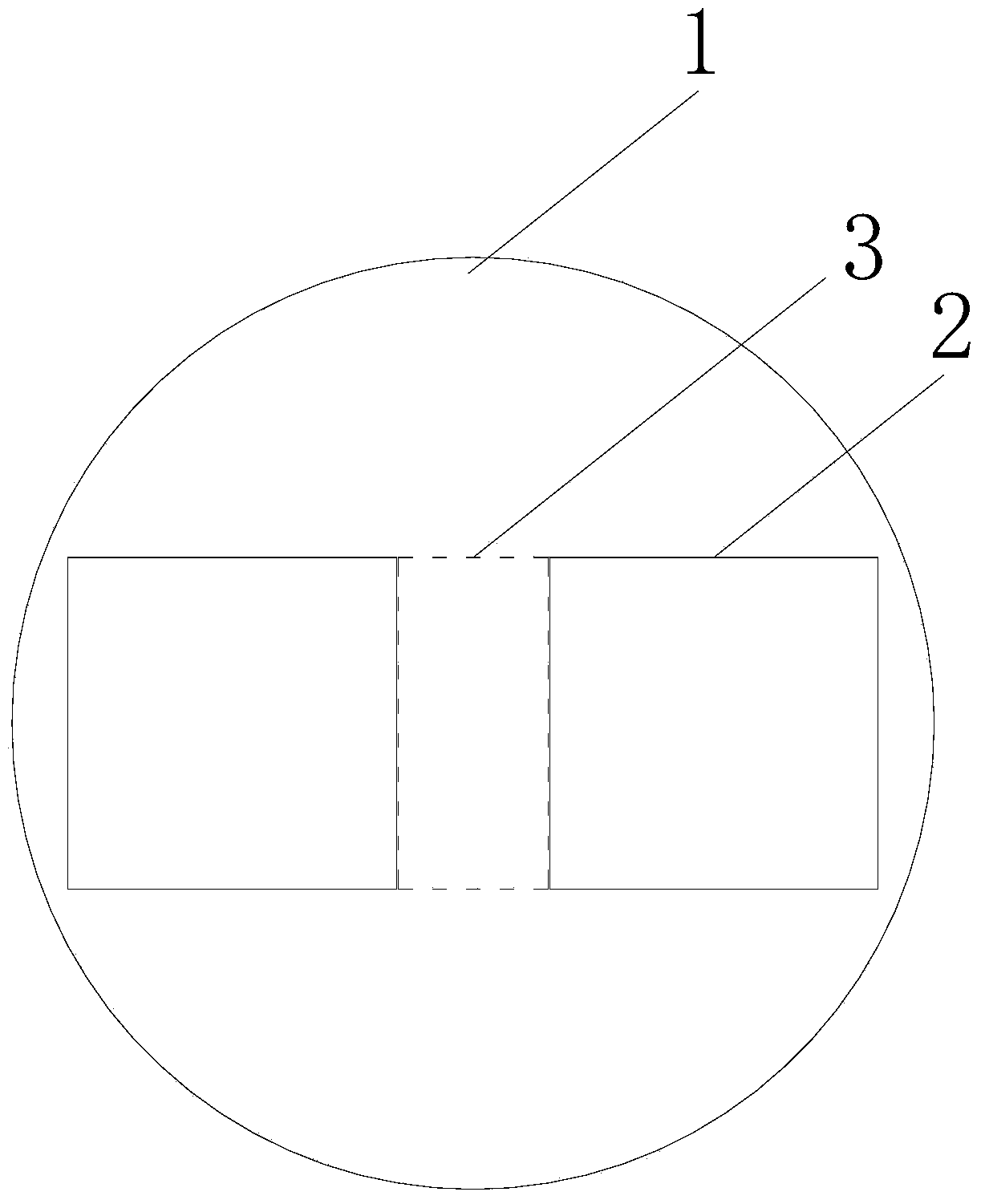

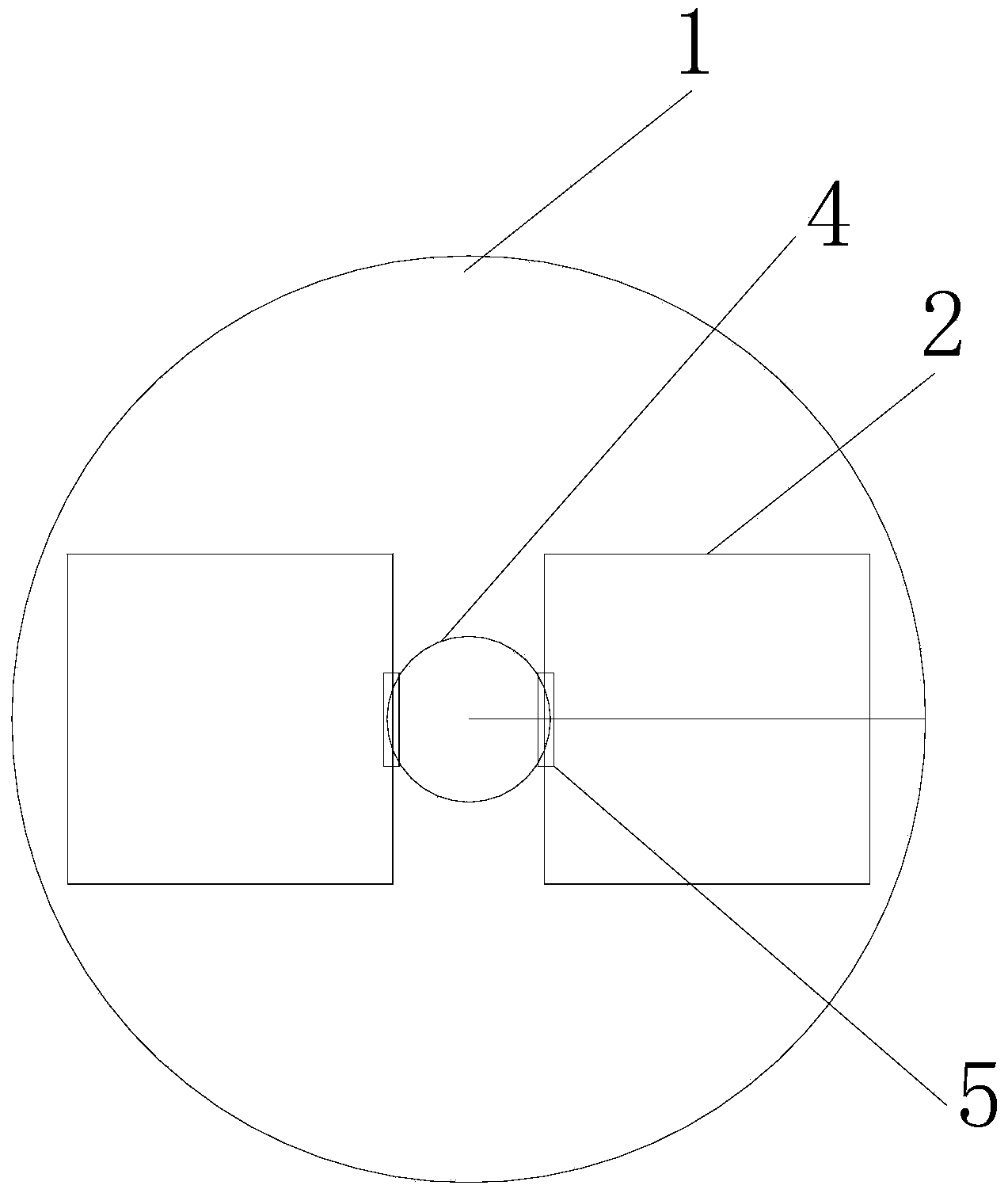

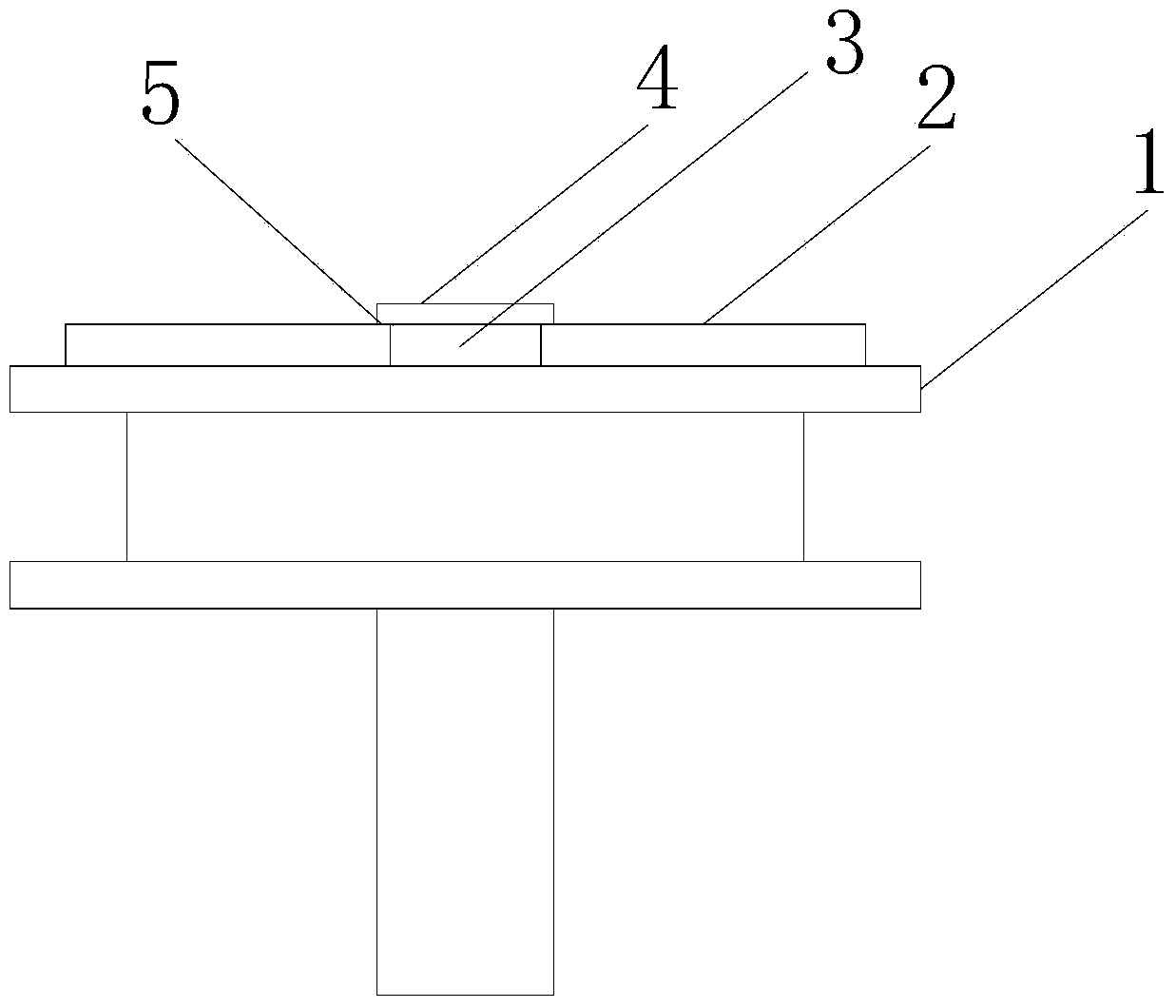

[0054] First, a carbon film copper grid frame with several samples placed on the surface is placed between two small silicon chips attached to the SEM / FIB sample holder, and the part of the carbon film copper grid in contact with the two small silicon chips is coated with There is silver glue to fix the carbon film copper mesh and two small silicon chips. There is a certain gap between the lower surface of the carbon film copper mesh and the SEM / FIB sample holder to ensure that subsequent nanoprobes will not be damaged due to contact with the surface of the sample holder when sampling.

[0055] Then, use the nanoprobe to find and extract the samples on the surface of the carbon film copper mesh that cannot be observed by TEM due to the thickness is too large.

[0056] Rotate the extracted sample th...

Embodiment 2

[0060] In this embodiment, the samples that need to be re-prepared are placed on the carbon-coated copper grid and located in the damaged area of the carbon-coated copper grid and cannot be observed by TEM.

[0061] The specific re-preparation method is as follows:

[0062] First, a carbon film copper grid frame with several samples placed on the surface is placed between two small silicon chips attached to the SEM / FIB sample holder, and the part of the carbon film copper grid in contact with the two small silicon chips is coated with There is silver glue to fix the carbon film copper mesh and two small silicon chips. There is a certain gap between the lower surface of the carbon film copper mesh and the SEM / FIB sample holder to ensure that subsequent nanoprobes will not be damaged due to contact with the surface of the sample holder when sampling.

[0063] Then, use the nanoprobe to find and extract the samples located in the damaged area of the carbon film copper mesh t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com