A X-ray Fluorescence Coupling Analysis Method of Multiple Elements in Mixed Copper Concentrate

A multi-element, copper concentrate technology, applied in the analysis of materials, material analysis using wave/particle radiation, measurement devices, etc. Realize problems such as joint measurement of major components and minor components, and achieve the effect of fast detection and analysis, saving sample analysis time, and saving sample processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the present invention will be described in further detail below through the description of the embodiments, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

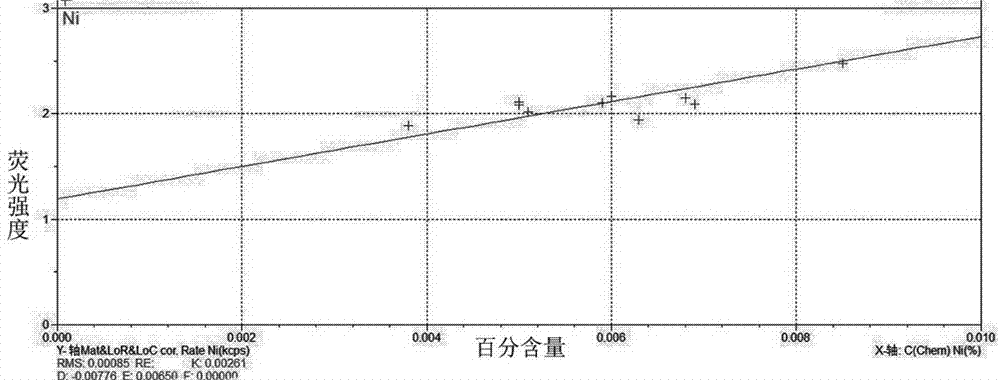

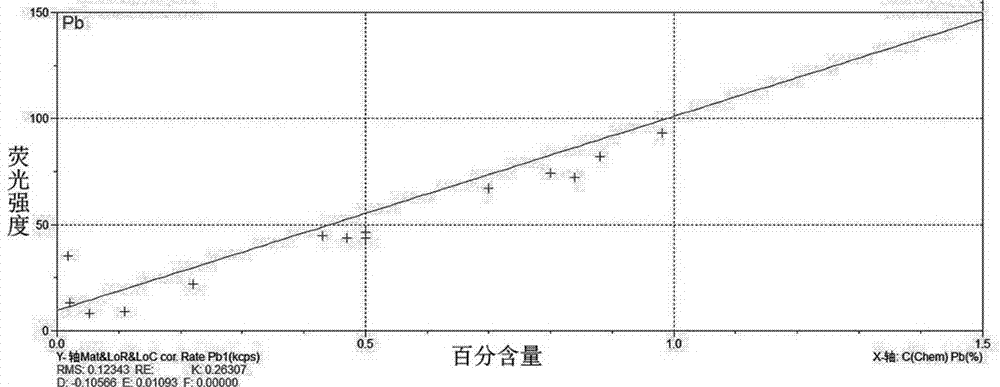

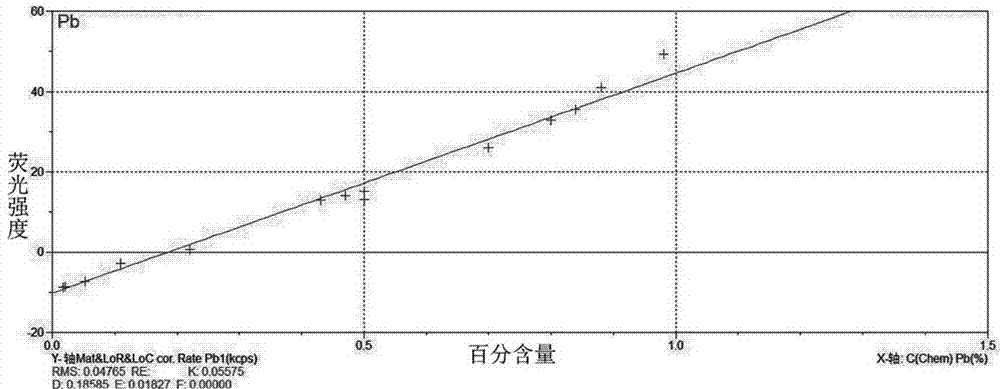

[0035] The present embodiment utilizes X-ray fluorescence spectrometry to analyze Ni, Cu, Fe, S, CaO, MgO, SiO 2 , Pb, Zn, As, Sb, Bi twelve kinds of elements, the percentage content of the compound is analyzed.

[0036] The instruments used include Axiosmax X-ray fluorescence spectrometer from Panaque Company in the Netherlands, GM / F3000-3 sample grinder from Nanchang Guangming Company, and ZHY401B-P sample press from Beijing Zhonghe.

[0037] The specific analysis process includes the following steps:

[0038] 1) Calibration of the X-ray fluorescence spectrometer: Take 100-150 g of the calibration samples whose content of each measured element is within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com