Eutectic bonding material-series structure used for wafer-level encapsulation

A wafer-level packaging and bonding material technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as weak adhesion and reduced strength, and achieve the effect of avoiding bonding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

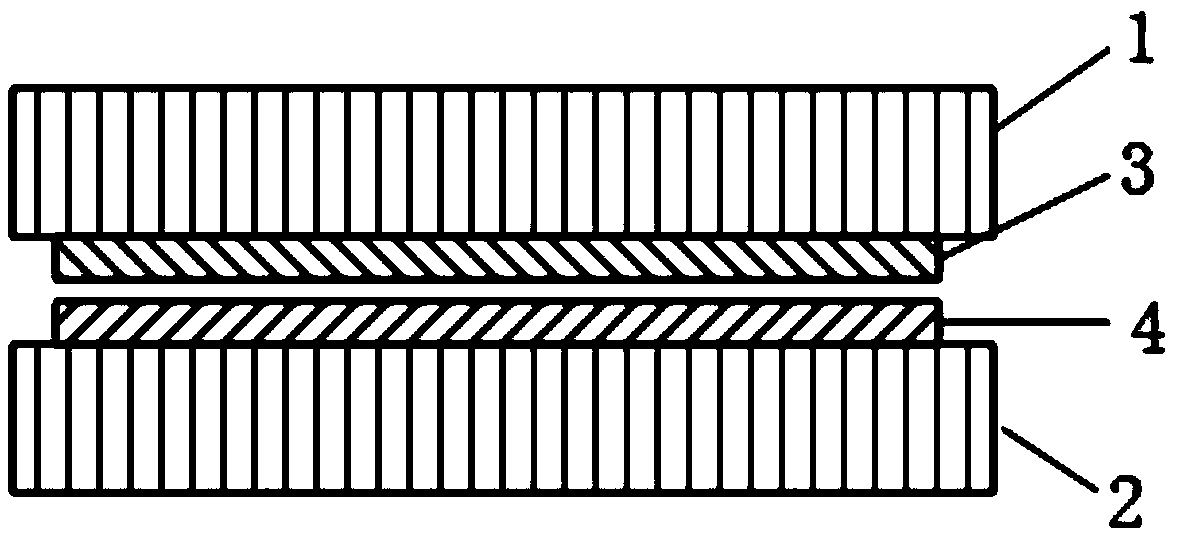

[0019] The present invention provides as figure 1 A eutectic bonding material system structure for wafer level packaging is shown, the structure includes a first substrate 1, a second substrate 2, a first bonding material 3 and a second bonding material 4; The first substrate 1 and the second substrate 2 and the first bonding material 3 and the second bonding material 4 are respectively composed of three kinds of materials that can form a ternary eutectic alloy; before bonding, the first bonding material 3 is directly attached to the first substrate 1, and the second bonding material 4 is directly attached to the second substrate 2.

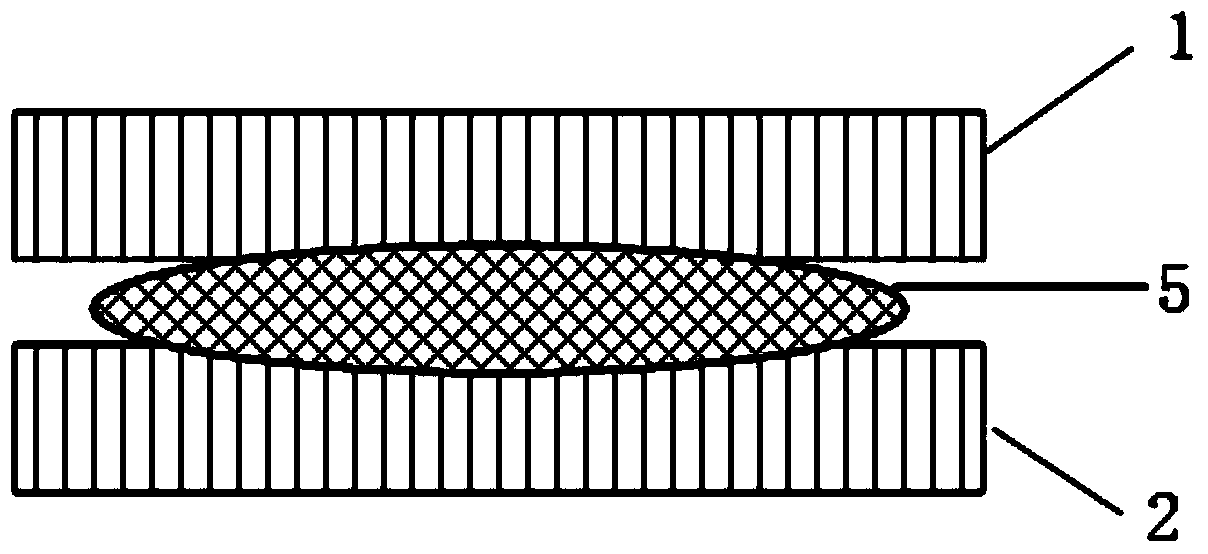

[0020] Such as figure 2 As shown, in the bonding process, when the temperature reaches the melting point of the ternary eutectic and the pressure is appropriate, the first bonding material and the second bonding material and the surfaces of the first substrate 1 and the second substrate 2 form a liquid state The ternary eutectic alloy 5.

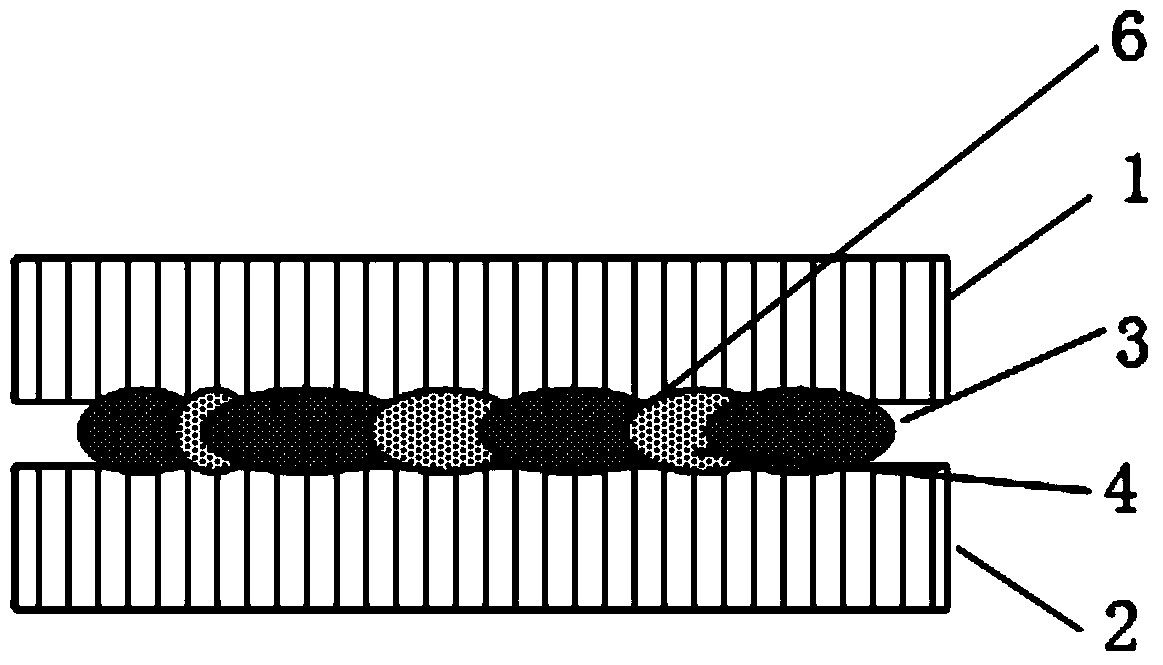

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com