Wafer bonding method and preparation method or packaging method of semiconductor device

A wafer bonding and bonding technology, applied in the field of semiconductor technology, can solve problems such as bonding failure and bonding bubbles, and achieve the effect of improving yield and avoiding bonding failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

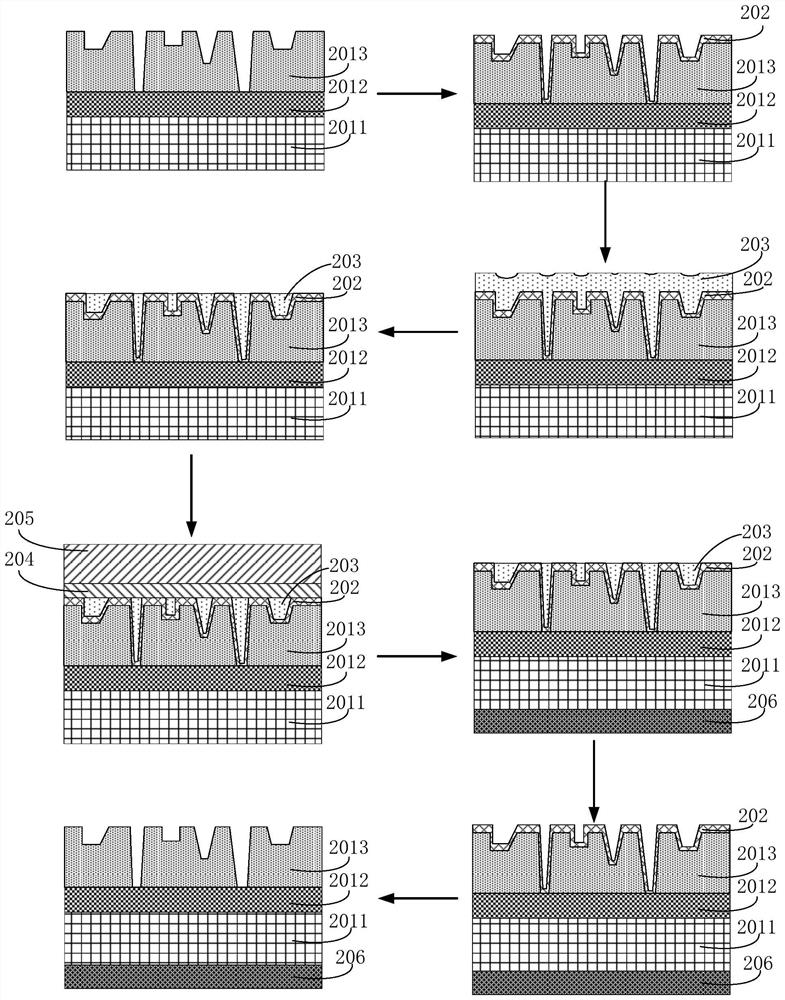

[0078] like image 3 As shown, this embodiment provides a method for wafer bonding. The wafer to be bonded 201 is a silicon carbide wafer having an engraved pattern layer 2013 that has been photoetched on one side, and the wafer to be bonded 201 includes a silicon carbide liner. Bottom 2011 , epitaxial layer 2012 and imprint pattern layer 2013 .

[0079] Step S10 : coating a polyimide with a thickness of 1 μm on the side of the wafer to be bonded 201 with the imprinted pattern layer 2013 to form the isolation layer 202 ;

[0080]Step S20: A silicon dioxide layer 203 is grown on the isolation layer 202 by using ethyl orthosilicate as a raw material by plasma enhanced chemical vapor deposition, and chemical mechanical polishing is used to remove excess silicon dioxide material, so that the silicon dioxide layer 203 is isolated from the Layer 202 is in the same plane to prepare a composite layer;

[0081] Step S30: forming a 20 μm bonding adhesive layer 204 and a bonding carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com