Improved magnesium oxychloride cement (MOC) and method of manufacturing

A technology of magnesium oxychloride cement and light-burning magnesium oxide, which is applied in the field of building material manufacturing and can solve problems such as metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The aim of the present invention is to achieve high performance MOC cement products with advantages over those currently used in the construction industry.

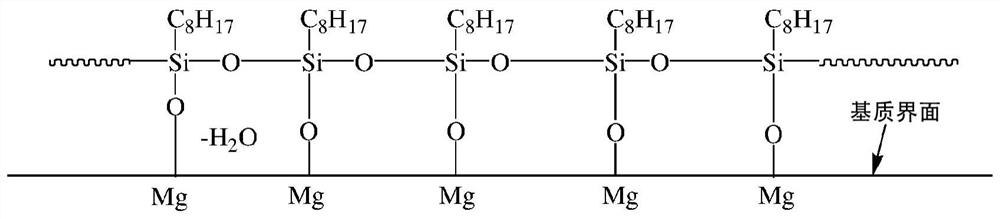

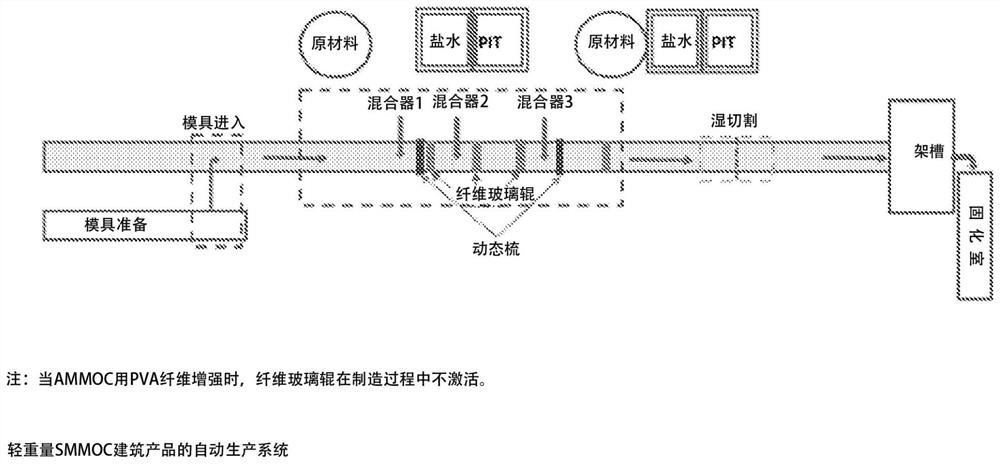

[0052] The new invention is a novel silane-modified magnesia cement (SMMOC) cement composition, wherein the molecular structure of magnesium oxychloride hydroxide cement is effectively protected from dissolving in water. It was developed by adding reactive cationic organosilanes to MOC mixtures. Thus, the water solubility of MOCs is reduced by minimizing the chances of reactions between water and MOC molecules. Water resistance and corrosion resistance are thereby improved. Carbon sequestration is also minimized, thereby mitigating the degradation of SMMOCs over a long period of time. For this reason, the ingredients and the amount of hydrophobic agent are carefully calculated when preparing the wet stock composition to produce the most effective finished SMMOC.

[0053] The present inventors have learned that e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com