Vehicle light assembly

A component and lamp technology, which is applied in the direction of headlights, vehicle parts, household components, etc., can solve problems such as failure of bonding, and achieve the effects of improving bonding strength, increasing bonding width, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

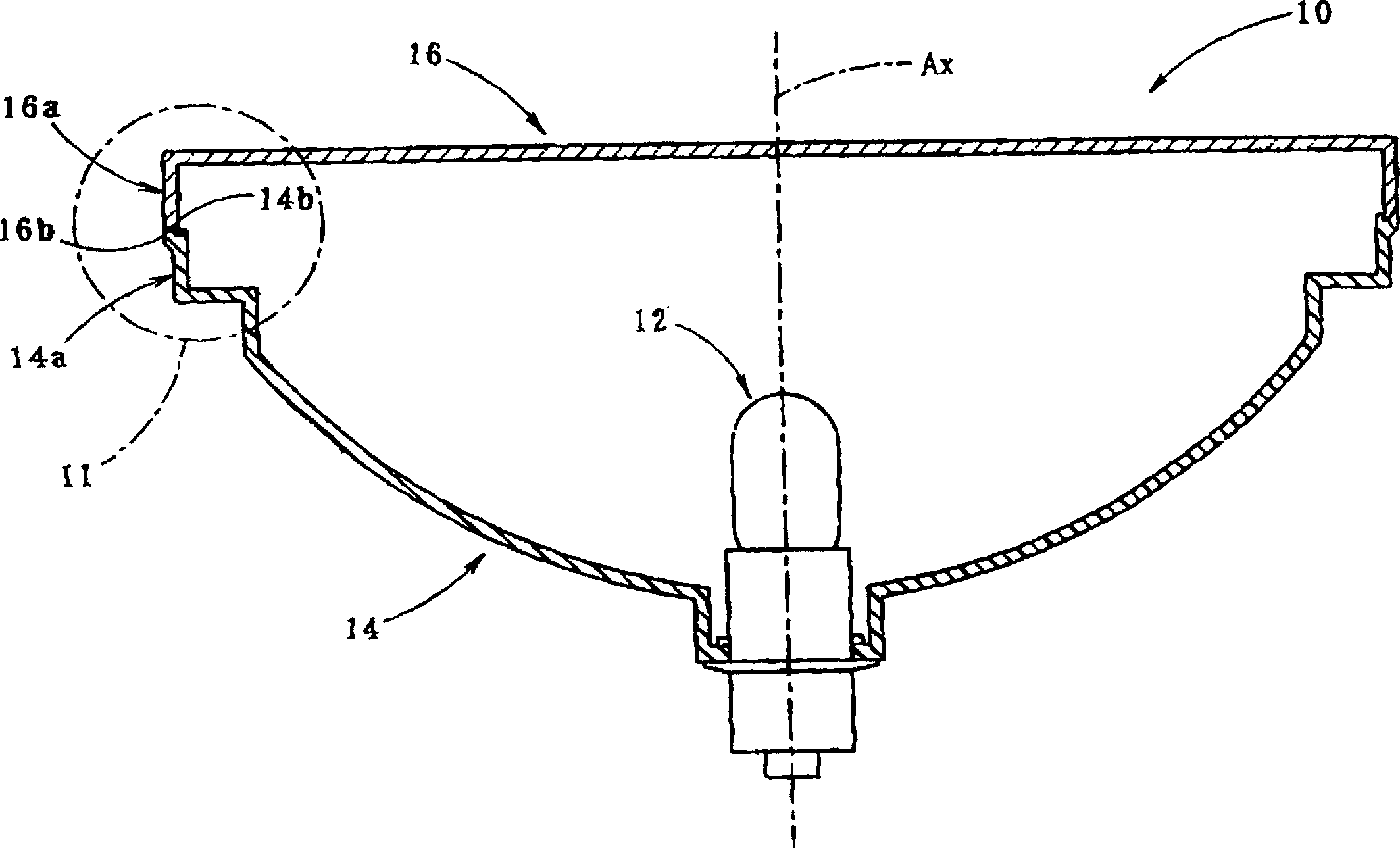

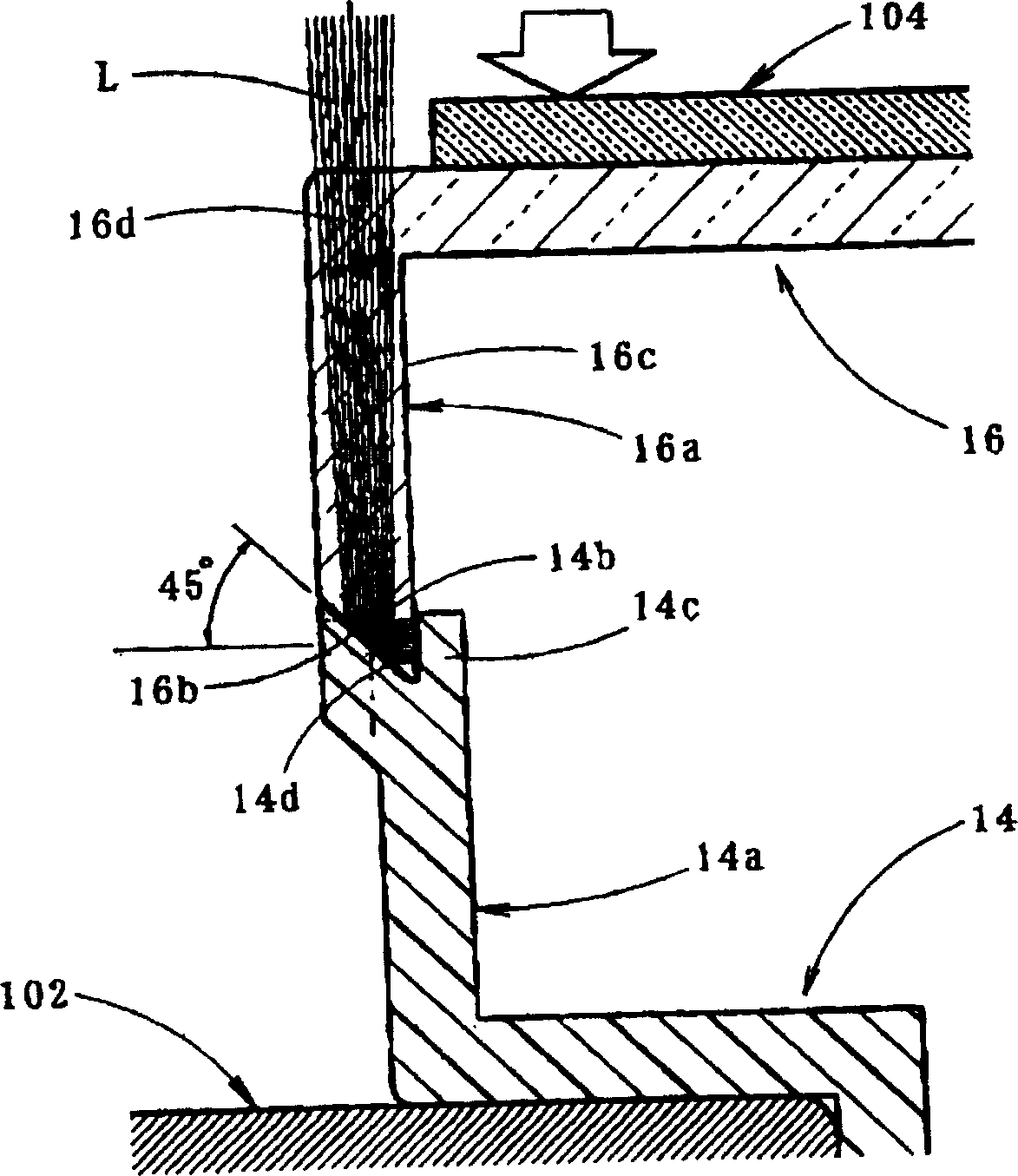

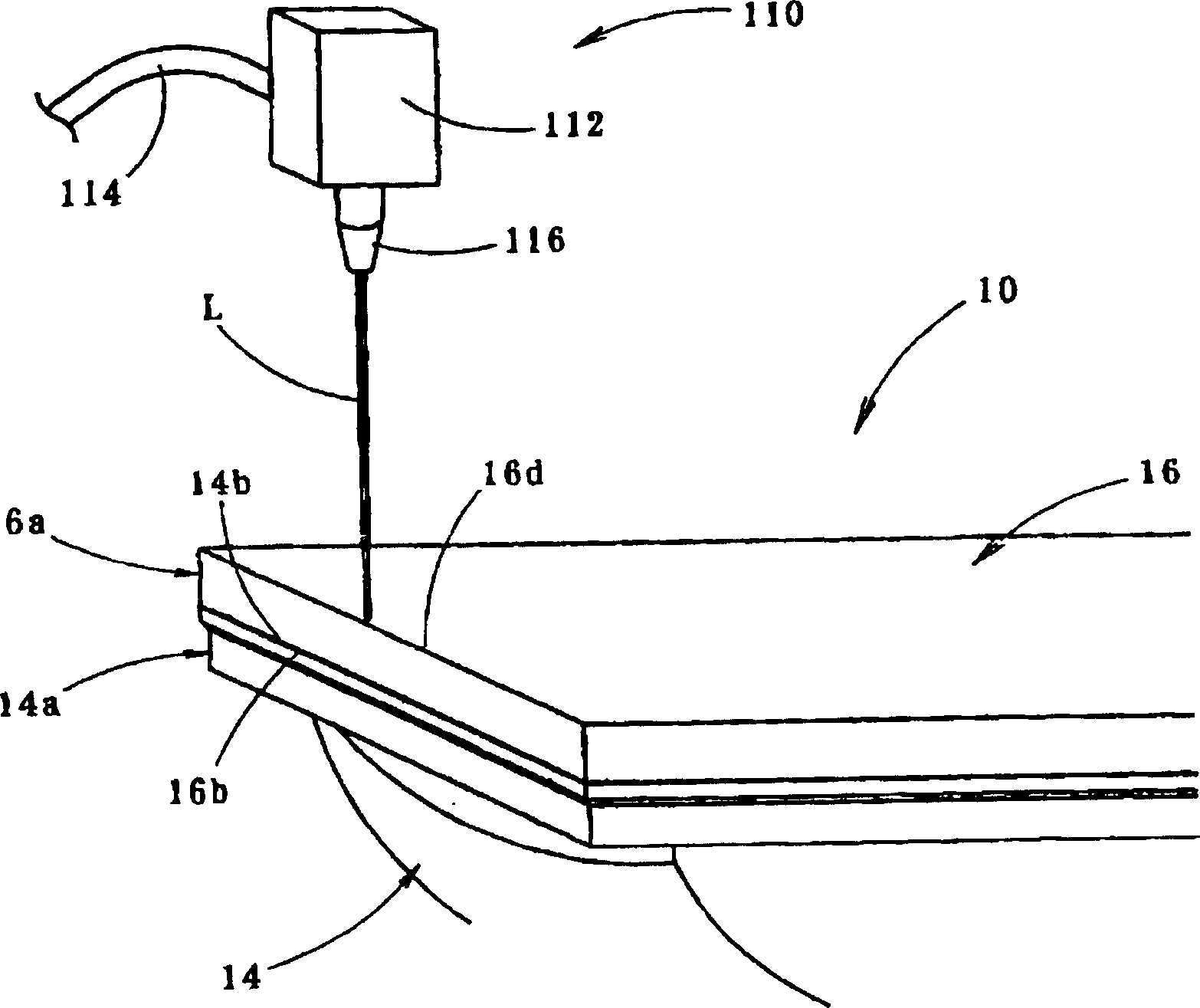

[0030] figure 1 is a side sectional view of a vehicle lamp of a preferred embodiment of the invention placed top up. figure 2 is shown in detail figure 1 View of Part II.

[0031] The vehicle light assembly 10 of the preferred embodiment is in the form of an indicator light such as a tail light. The lamp has a lamp body 14 and a headlight glass 16 directly bonded to the lamp body 14, a light source bulb 12 extending vertically (in the longitudinal direction relative to the lamp body assembly) is installed on the lamp reference axis Ax of the lamp body 14, The headlight glass 16 is directly bonded to the lamp body 14 .

[0032] The headlight glass 16 is made of a transparent thermoplastic resin material such as PMMA or PC. The outer periphery of the headlight glass 16 is provided with a sealing foot 16a projecting downward over the entir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com