Wafer Defect Inspection Method

A defect detection and wafer technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as reducing defect detection accuracy, reducing process efficiency, increasing process steps, etc., to improve defect recognition rate, Improve adaptability and facilitate the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

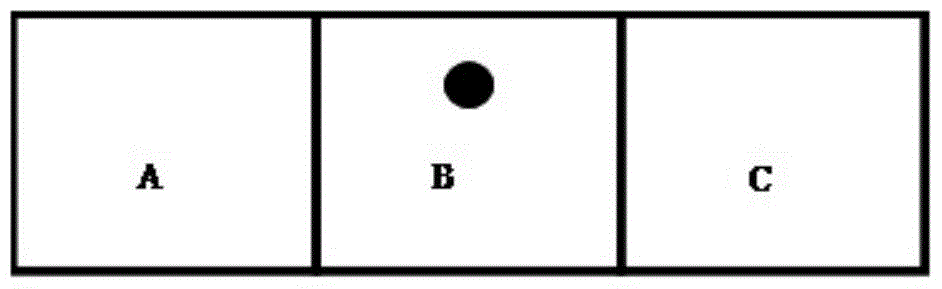

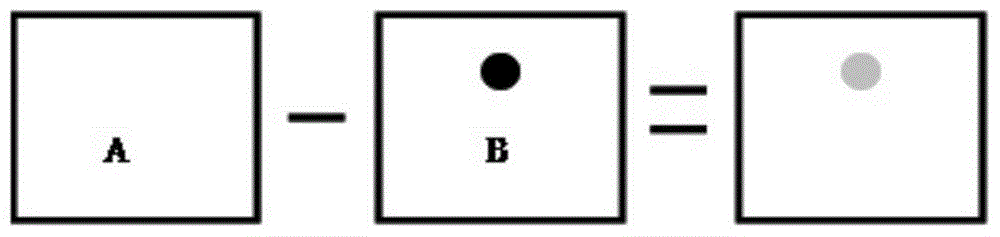

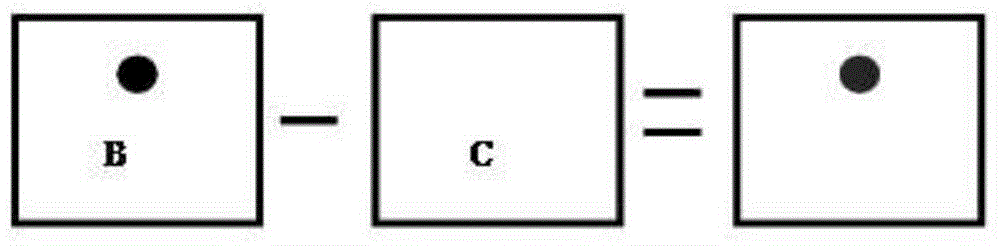

[0017] It should be noted that the wafer includes a plurality of chip areas, and the chips are separated by dicing lines. The detection of wafer defects is essentially the detection of defects on each chip. In the embodiment provided by the present invention, the detection of wafer defects by the detection beam is used in combination with an industrial camera. The area on the wafer on which the detection beam is projected is observed by the industrial camera, and combined with certain image processing measures, the image gray The identification and comparison of high-degree features can effectively detect defects on the wafer.

[0018] Such as image 3 As shown, the wafer defect detection method provided by an embodiment of the present invention includes the following process steps:

[0019] Step S10 , detecting the film thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com