Method and apparatus for moving and positioning a gripping unit, and a robot provided with gripping unit

A gripping unit, robot technology, applied in mechanical equipment, manipulators, program-controlled manipulators, etc., can solve problems such as high torque, high robot cost, increased robot damage, etc., achieve fast and accurate control systems, simplify programmable logic , the effect of simplifying movement and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

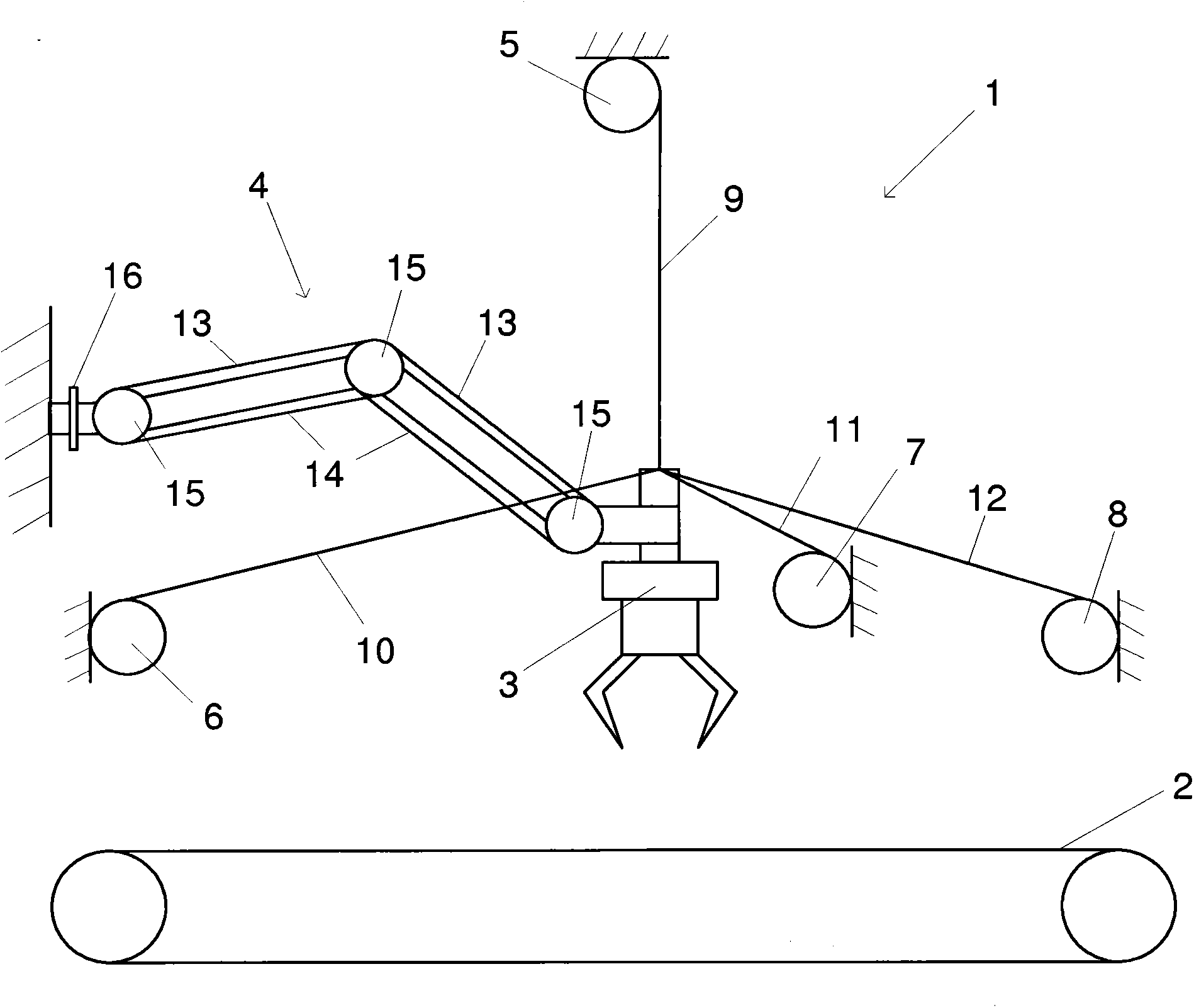

[0031] figure 1 The schematically shown arrangement according to the invention describes a sorting robot 1 for handling construction waste which is arranged to work in conjunction with a conveyor 2 for transporting construction waste.

[0032] The sorting robot 1 comprises a gripping unit 3 , a mechanical support arm 4 fastening the gripping unit to the supporting structure and four servo capstans 5 , 6 , 7 and 8 connected by means of cables 9 , 10 , 11 and 12 to gripping unit 3.

[0033] The mechanical fastening arm 4 of the gripping unit 3 has two elements, and each element of the fastening arm 4 is formed by two parallel bars or shafts 13 and 14, both articulated to a connection 15 via its own pivot joint . Therefore, when the gripping unit 3 is moved by means of the servo winches 5 , 6 and 7 and through the cables 10 , 11 and 12 in the XYZ plane, the gripping unit cannot perform a rotational movement relative to the mechanical fastening arm 4 . The mechanical fastening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com