Machine for picking up, cleaning up and packaging residual film

A residual film picking and residual film technology, applied in collectors, agricultural machinery and implements, applications, etc., can solve the problems of low work efficiency, high labor cost, a lot of manpower, etc., to improve work efficiency, simple structure, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

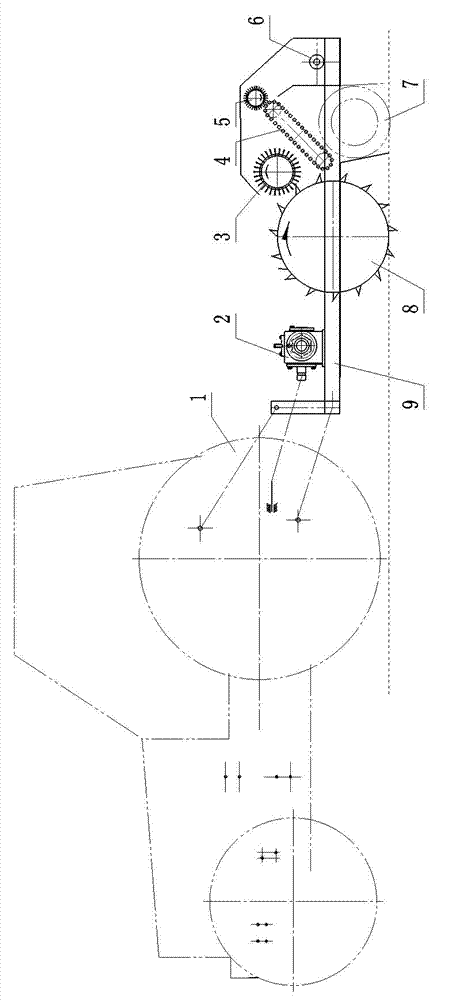

[0022] refer to figure 1 — Figure 9 , a residual film picking and cleaning packing machine, including a frame 9, a transmission device 2, and a traveling wheel 7, and is characterized in that a film removal roller 8 is provided at the front of the frame, and a film brushing roller is arranged at the oblique rear of the film removal roller 8 A3, the rear of the described film removal cylinder 8 is provided with a residual film cleaning device 4, a film brushing roller B5 is provided near the end of the residual film cleaning device 4, and a film brushing roller B5 is arranged behind the residual film cleaning device 4 and the film brushing roller B5. A residual film packing device 6 is arranged.

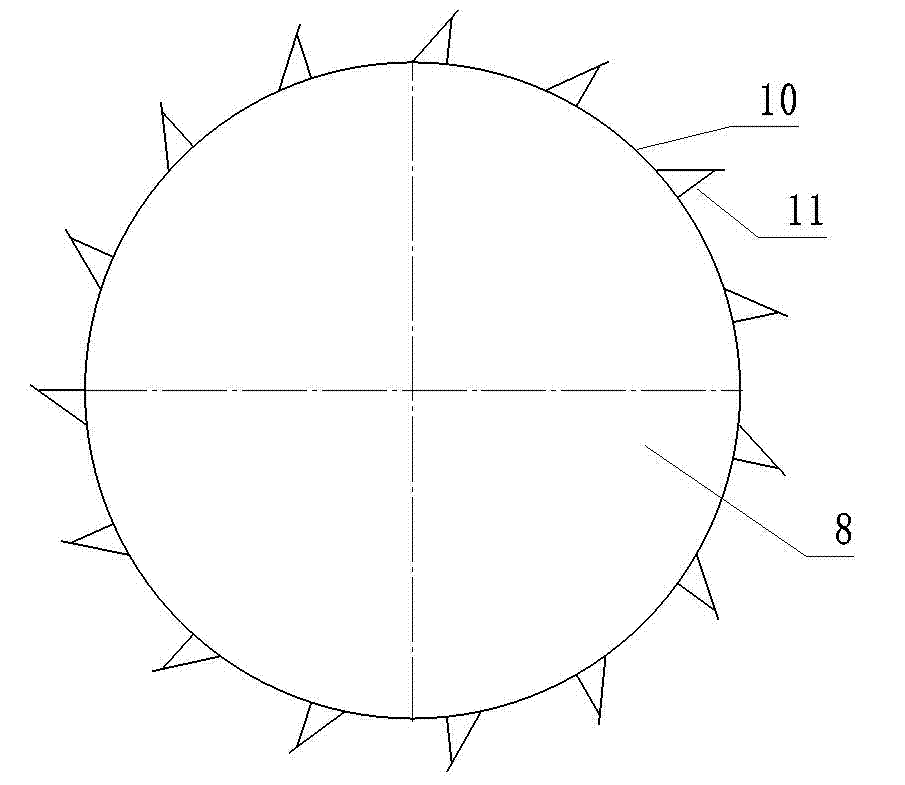

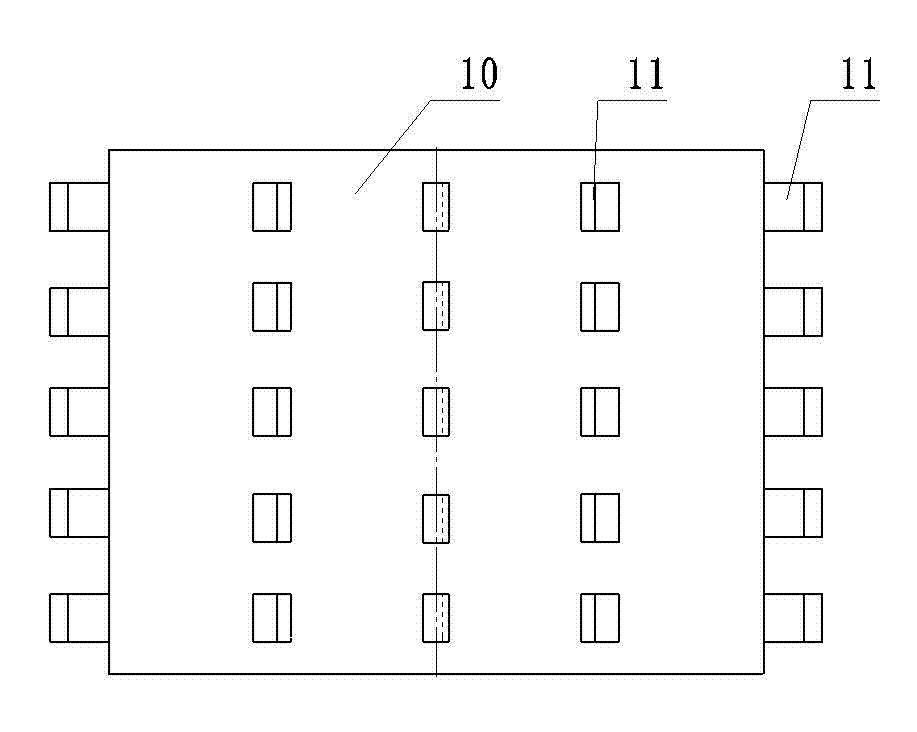

[0023] The structure of the film-raising cylinder 13 includes a circular cylinder 10, on which the outer peripheral surface of the circular cylinder 10 is provided with pick-up teeth 11, and the pick-up teeth 11 are formed by two plates fixed vertically at an included angle. .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com