A kind of instant molecular health tea

A technology of instant molecules and health-care tea, applied in the direction of tea substitutes, etc., can solve the problems of inconvenient carrying, inconvenient drinking, incomplete absorption, etc., and achieve the effects of enhancing absorption and utilization, promoting endocrine balance, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0021] Instant tea includes instant tea raw materials, and the processing process of instant tea raw materials is as follows:

[0022] Take 18-20 parts of Bailingzhi, 15-18 parts of Polygonum multiflorum, 12-18 parts of hemp seed, 12-17 parts of knotweed, 9-11 parts of hawthorn, 8-13 parts of radish, 8-15 parts of cassia, 5-8 1 part of Luo Han Guo and 2 to 9 parts of lemon are respectively crushed, mixed to obtain a mixture, soaked in water, and emulsified to obtain an emulsion. The pulverization needs to pass through a 20-40 mesh sieve, the amount of water added is 12-25 times that of the mixture, the soaking temperature is 50-60° C., and the soaking time is 20-60 minutes.

[0023] Using a low pressure of 3MPa-5MPa and a high pressure of 18MPa-20MPa, the emulsion obtained in step S1 is subjected to differential pressure wall-breaking extraction to obtain an extract, and the solvent for the extraction described in S2 is normal temperature purified water.

[0024] The extract ...

Embodiment 10

[0034] Embodiment 10 Grinding fineness, soaking time, water addition orthogonal test

[0035] According to the steps in Example 1, and wherein the crushing fineness, soaking time and water addition are controlled, to confirm the aforementioned three

[0036] optimal value of the variable. The specific variable parameter control of the test is shown in Table 3, the test results are shown in Table 4, and the obtained extract density is shown in Table 5.

[0037] Table 3: Orthogonal factor level table

[0038]

Soaking time (min)

Amount of water added (times)

1

20

15

15

2

30

30

20

3

40

45

25

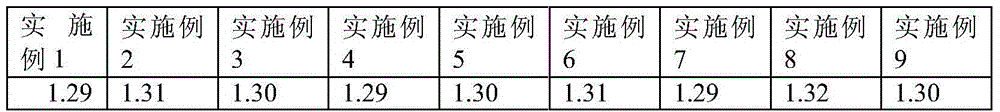

[0039] Table 4: Yield and polysaccharide content of Examples 1-9

[0040]

[0041] Through the above examples, the crushing fineness is 30 mesh, the soaking time is 45 minutes, and the amount of water added is 25 times, and the paste yield is the highest, and the polysacchar...

Embodiment 11

[0045] Embodiment 11 Determination of finished product active ingredients

[0046] The extracts extracted in the above-mentioned Examples 1-9 were vacuum-dried, and after drying, they were broken into yellow-brown crystalline coarse powder.

[0047] Determination of this process: Since the entire production process is kept at low temperature, the active ingredients and aroma are retained to the greatest extent.

[0048] Crush the dry product into coarse powder, then pack it separately, and pack 0.5g in each bag. The dosage method is: 3 to 4 bags per day, one bag each time, and add 200-250ml of hot and cold water to prepare it. Ready to drink. Check the turbidity of tea soup, and detect the content of active ingredient total polysaccharides and total flavonoids, the results are shown in table 6

[0049] Table 6 Content comparison of total polysaccharides and total flavonoids in finished products and raw materials and turbidity of finished products after brewing

[0050]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com