Method and equipment for evaporative crystallization of aluminium chloride

A technology of evaporative crystallization and aluminum chloride, applied in the direction of solution crystallization, multi-effect evaporation, etc., can solve the problems of equipment, pipeline corrosion, harsh operating environment of workers, affecting the service life of equipment, etc., so as to avoid equipment corrosion and environmental pollution. , Reduce secondary steam pollution and solve the effect of small processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

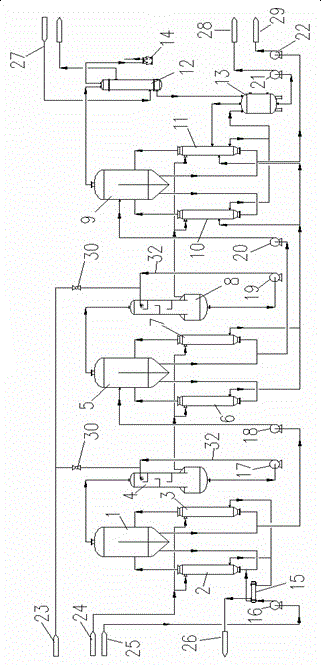

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following specific implementation method is an example of a double-chamber double-tube-pass evaporator. As for the principle of the three-chamber three-tube-pass evaporation process, it is the same as the double-chamber double-tube-pass evaporation process, and the equipment is similar. No more detailed description here, but all belong to the protection scope of the present invention.

[0022] An aluminum chloride evaporative crystallization device according to the present invention comprises a multi-effect evaporation device including a separation chamber and a heating chamber which is connected to an aluminum chloride raw material liquid pipeline and / or a steam main pipe through pipeline communication. The pipeline between the first-effect separation chamber and the next-effect heating chamber is connected with a washing tower having the same temperature a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap