Flat-bag dust remover device and fireproofing process thereof

A technology of a dust collector and a flat bag is applied in the field of a flat bag dust collector device and its fire prevention technology, which can solve the problems of not being able to ensure the safety of life and equipment and property, and the inability to detect sparks in the dust removal and conveying pipelines, so as to ensure the safety of life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the drawings.

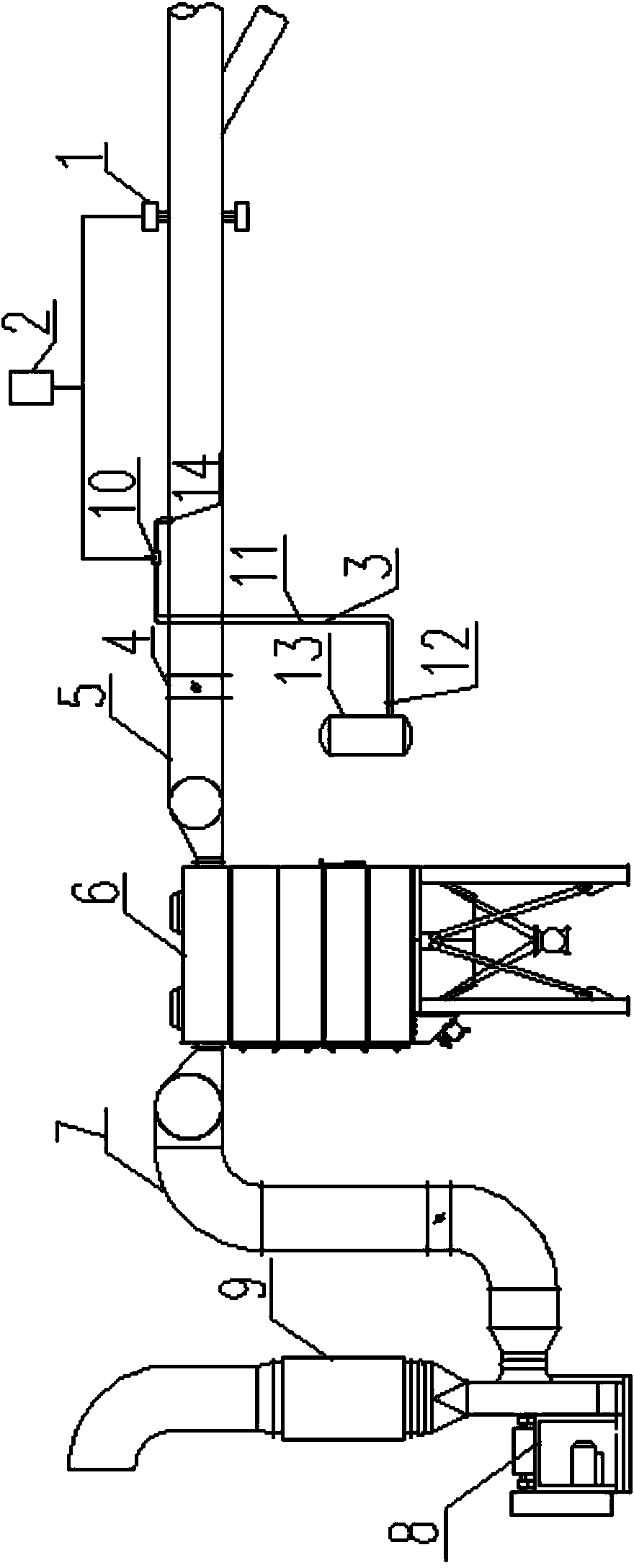

[0020] Such as figure 1 As shown, a flat bag dust collector device includes a spark detector 1, a controller 2, a spray device 3, a pneumatic butterfly valve 4, a dust removal pipe 5, a flat bag dust collector 6, a dust collector exhaust pipe 7, a fan 8 and The muffler 9; the spark detector 1 is arranged at the upstream position of the dust removal pipe 5, and the controller 2 is connected to the spark detector 1; the spray device 3 and the pneumatic butterfly valve 4 are sequentially arranged on the dust removal pipe 5 and the spark The back of the detector 1; connected to the dust removal pipe 5 is a flat bag dust collector 6, the flat bag dust collector 6 and the fan 8 are connected through the dust collector exhaust pipe 7, and the air outlet of the fan 8 is provided with Muffler 9.

[0021] The spray device 3 includes a spray solenoid valve 10, a spray pipe 11, a switch v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap