A Pneumatic Agricultural Material Variable Spreading System and Method

A pneumatic and material technology, applied in the field of material spreading, can solve the problems of increased unit size, difficult control of uniformity, limited operating width, etc., and achieve the effect of increased coverage area, simple and light structure, and widened coverage width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

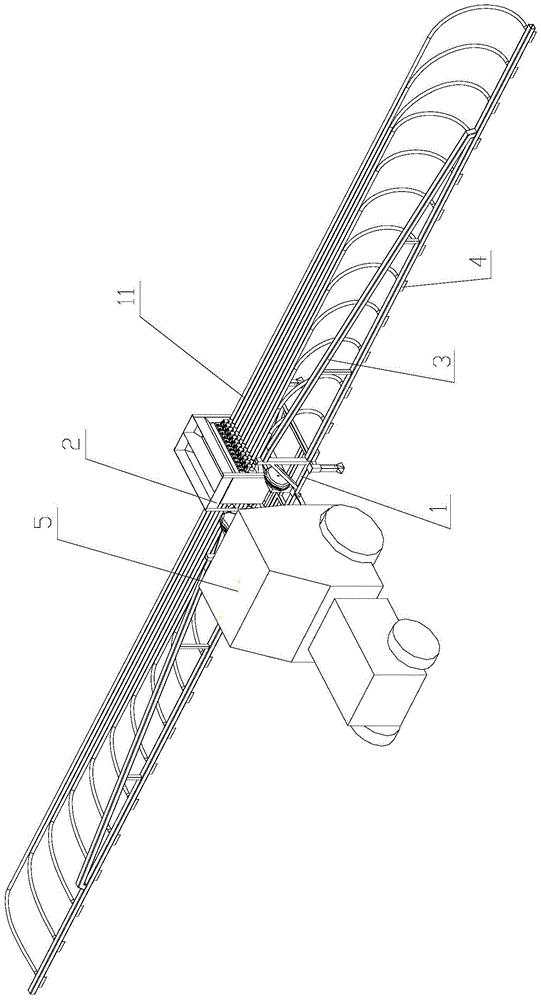

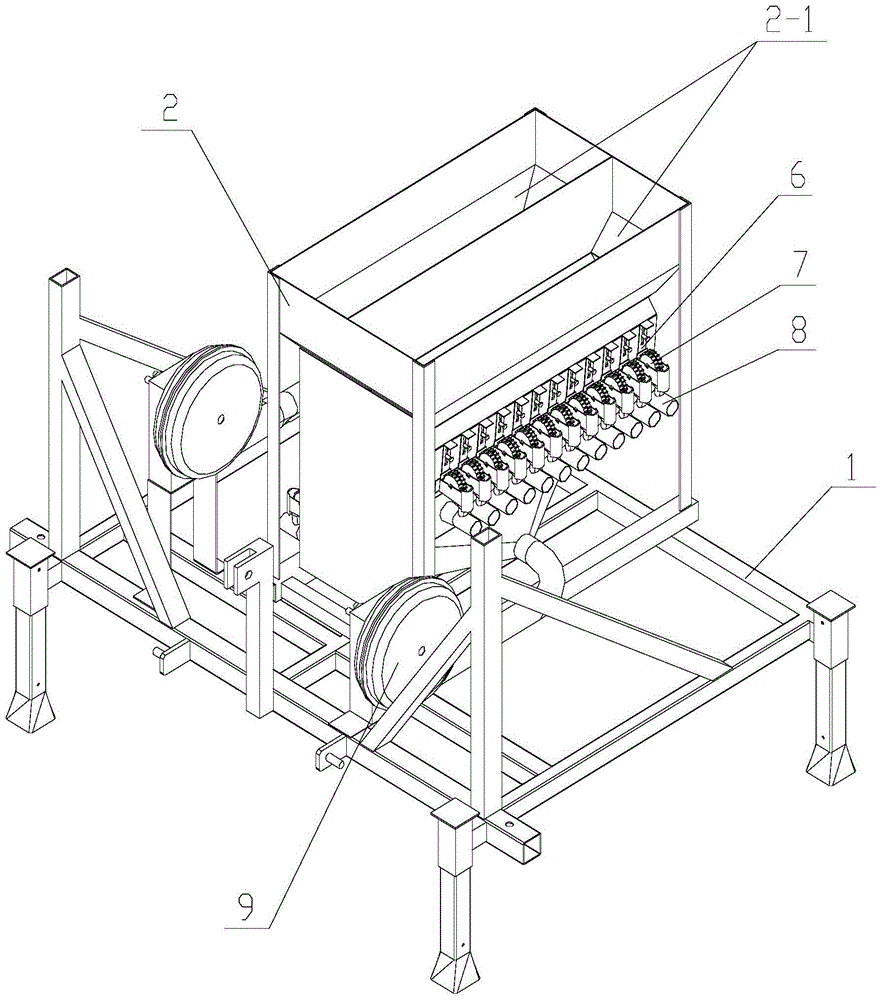

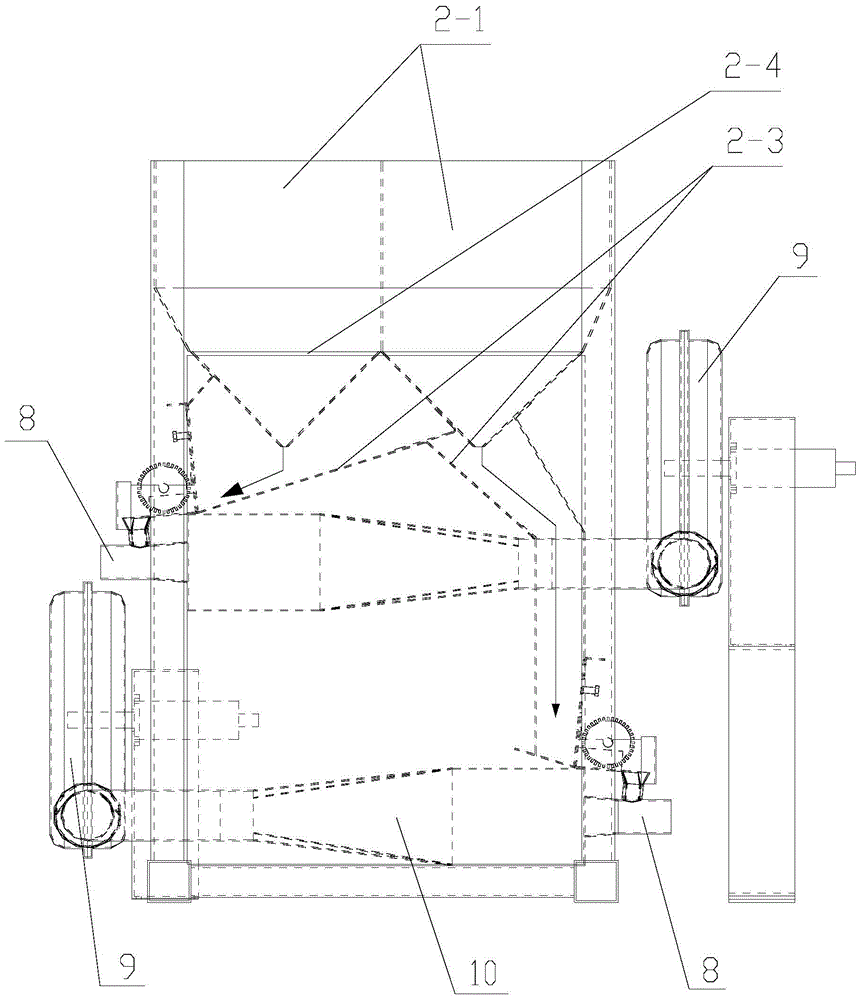

[0036] In this embodiment, a pneumatic variable spreading system for agricultural materials, such as figure 1 or figure 2 As shown, it includes a frame 1, a material holding box 2, a material variable control module, a pneumatic conveying module, a spreading load-bearing truss 3 and a spreader 4, and the frame is connected to a power chassis 5. In this embodiment, the power chassis is a tractor. The material holding box is arranged on the frame, and the material holding box is connected with the material variable control module, and the material variable control module is connected with the spreader 4 installed on the spreading bearing truss 3 through the pneumatic conveying module. The material to be spread enters the spreading system from the material storage box, and then its flow is controlled by the material variable control module, and then sent to the pneumatic conveying module, and the material is conveyed to the spreaders installed on the spreading bearing truss by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com