Manufacturing method for pulling boring machine boring rod central frame

A production method and center frame technology, which are applied in the direction of manufacturing tools, boring/drilling, large fixed members, etc., can solve problems such as damage to the boring bar, increase the deviation of the machined hole, affect the service life of the boring bar, etc. Convenient and reliable, prolong service life, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

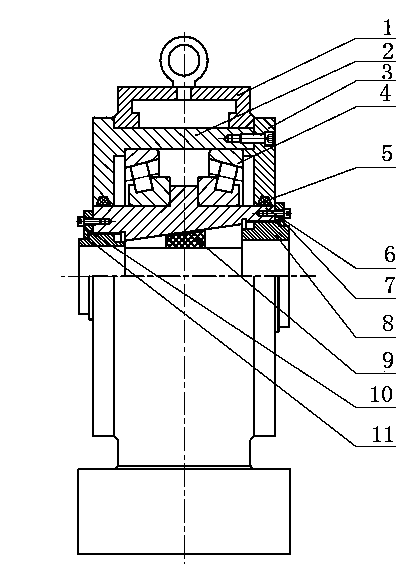

[0018] Reference figure 1 , The manufacturing method of the boring bar center frame of the pull boring machine of this embodiment is to install the support seat 1, the bearing outer cover 2, the bearing adjusting and fixing plate 3, the roller bearing 4, the blanket gasket 5, the bearing inner sleeve 6, and the right adjusting thread according to the drawings. Fixing plate 7, right adjusting thread 8, adjustable taper sleeve 9, left adjusting screw fixing plate 10 and left adjusting thread 11, the boring bar passes through the central bore of the bearing inner sleeve 6, the central bore of the bearing inner sleeve 6, the middle section is The cone-shaped, adjustable cone sleeve 9 is installed between the boring bar and the bearing inner sleeve 6. The adjustable taper sleeve 9 is in the shape of a frustum, the central aperture of the adjustable taper sleeve 9 is mounted on the bearing inner sleeve 6 as a frustum-shaped section, and the smallest diameter of the adjustable taper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com