Bogie axle box suspension device

A suspension device, bogie shaft technology, applied in the direction of axle box installation, axle box, transportation and packaging, etc., to reduce processing difficulty, reduce noise, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is specifically described below by way of embodiment, and present embodiment is only used to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, some non-compliances that those skilled in the art make according to the content of the present invention above-mentioned Essential improvements and adjustments also belong to the protection scope of the present invention.

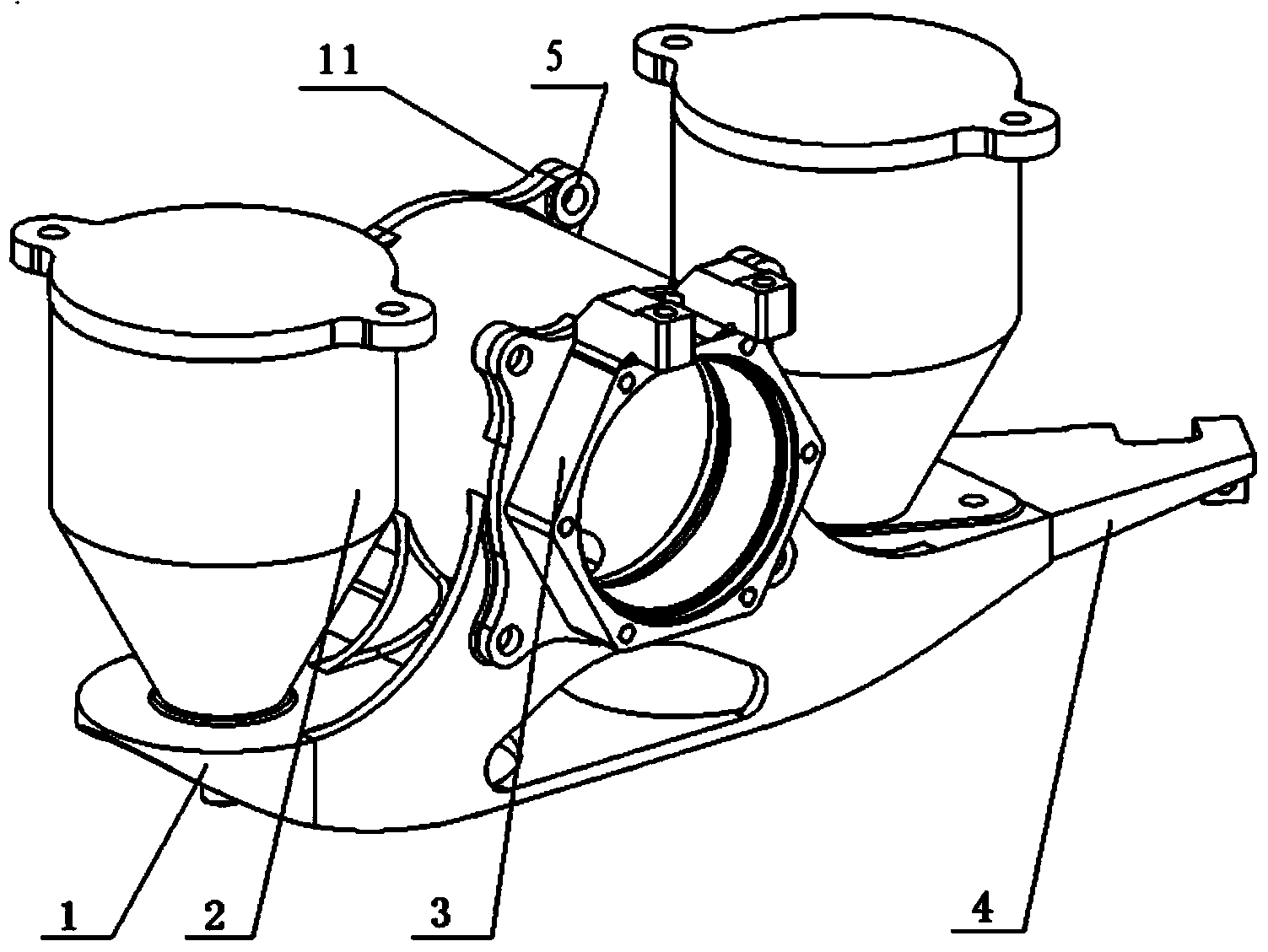

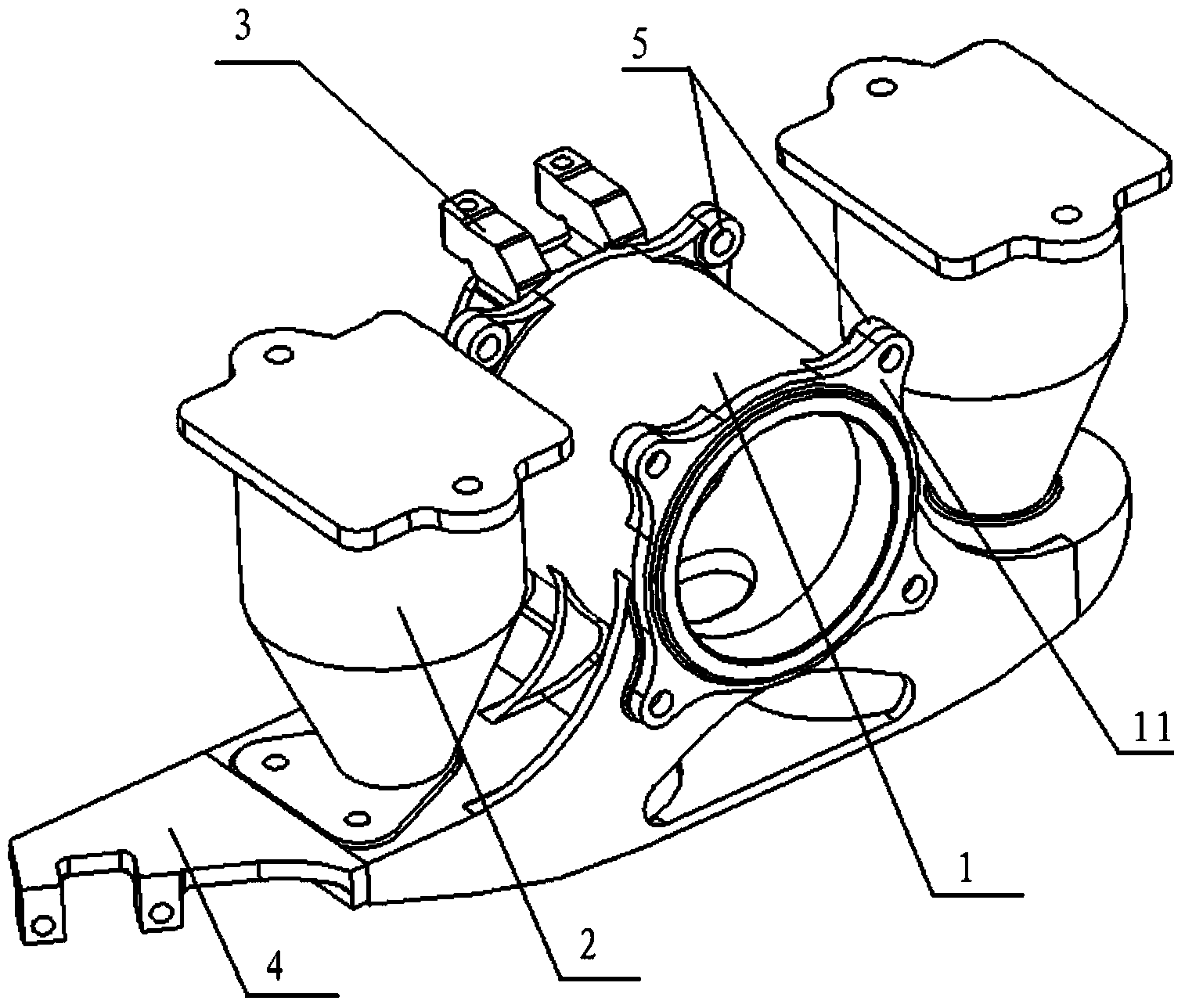

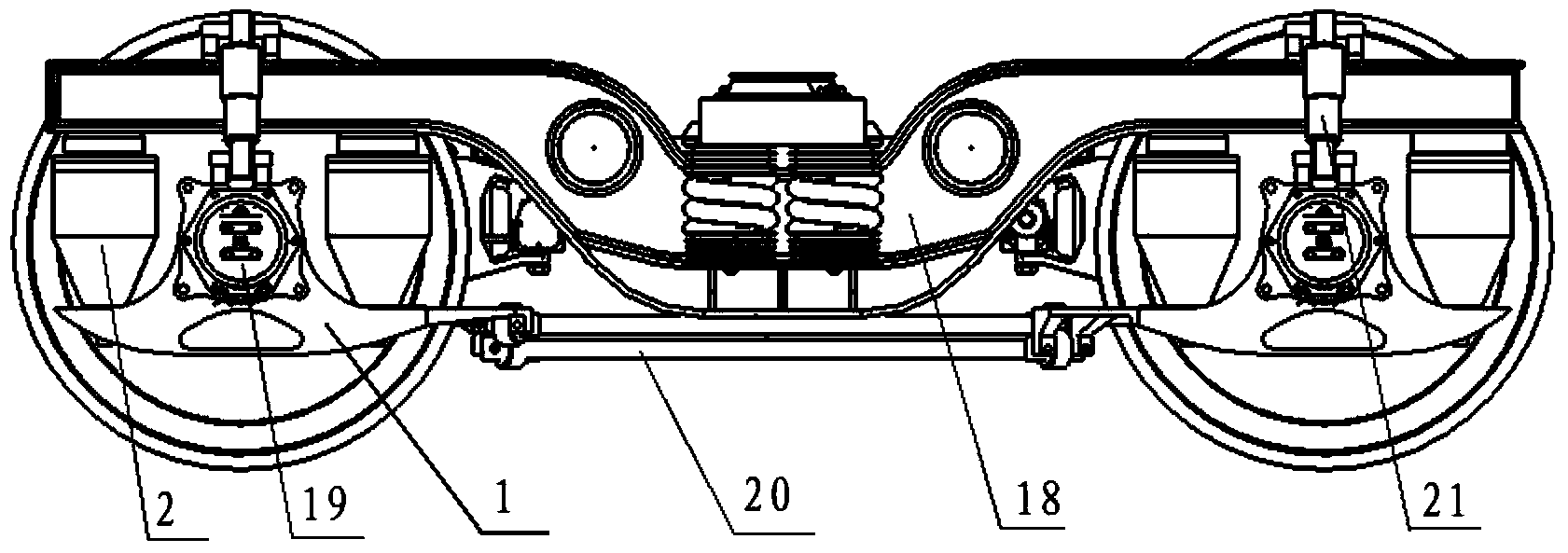

[0034] combine Figure 1 to Figure 8 .

[0035] As shown in the figure, the bogie axle box suspension device includes an axle box 1 matched with the axle 22 and a rubber spring 2 connected with the bogie frame 18. The axle box 1 is an integral structure formed by machining after integral casting. The axle box 1 It includes an axle hole seat 7 that fixes the bearing and cooperates with the axle shaft 22, and rubber springs 2 are respectively arranged on both sides of the axle hole seat 7.

[0036] There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com