Steering gear gap adjusting mechanism and method and vehicle

A technology of clearance adjustment and steering gear, applied in the field of auto parts, can solve the problems of inability to respond quickly and the response can only be linear, and achieve the effect of improving NVH performance, stable process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

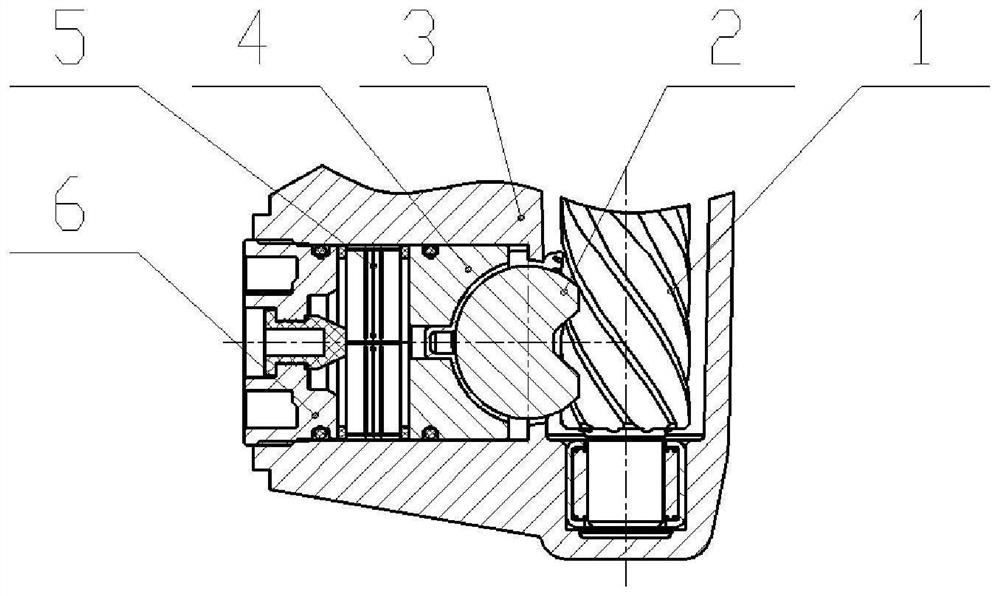

[0039] see Figure 1 to Figure 7 As shown, a steering clearance adjustment mechanism includes a housing 3 , a gear 1 , a rack 2 , a pressing block 4 , a bushing 5 and an adjusting screw plug 6 . The gear 1 and the rack 2 mesh with each other in the housing 3 , and the housing is provided with an adjustment hole, and the adjustment hole is connected with a gap adjustment assembly for adjusting the gap between the gear 1 and the rack 2 . Specifically, the gap adjustment assembly includes a pressure block 4 that is movably connected to one end of the adjustment hole and pressed to the rack, an adjustment screw plug 6 that is threadedly connected to the other end of the adjustment hole, and a pressure block 4 and the adjustment screw plug 6. The bushing 5 acts on the pressing block 4 and is used to limit the radial movement of the rack 2 along the gear 1 .

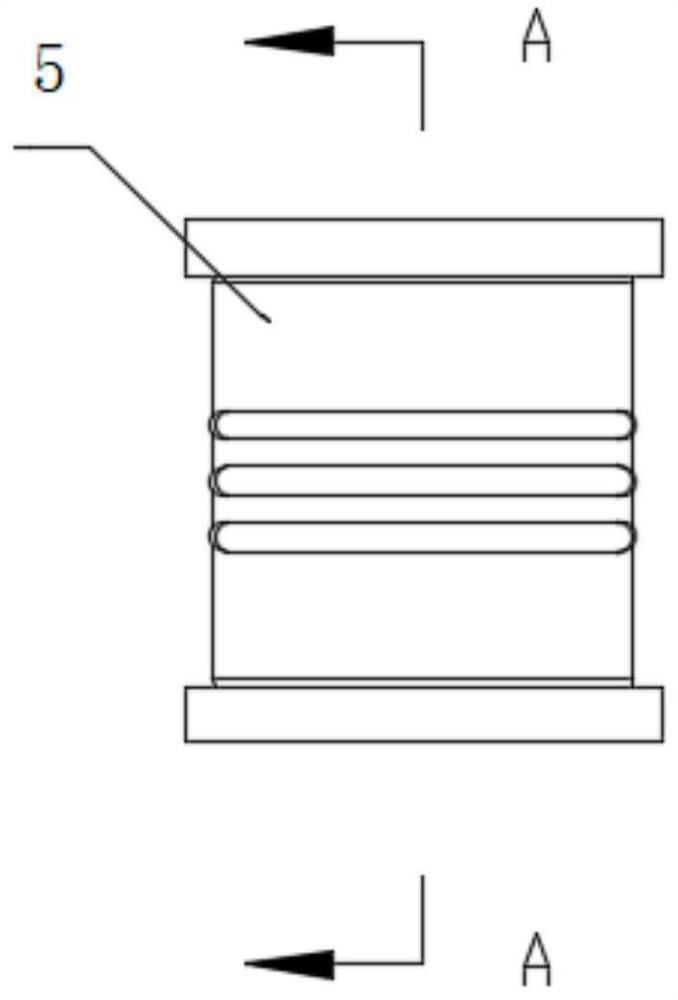

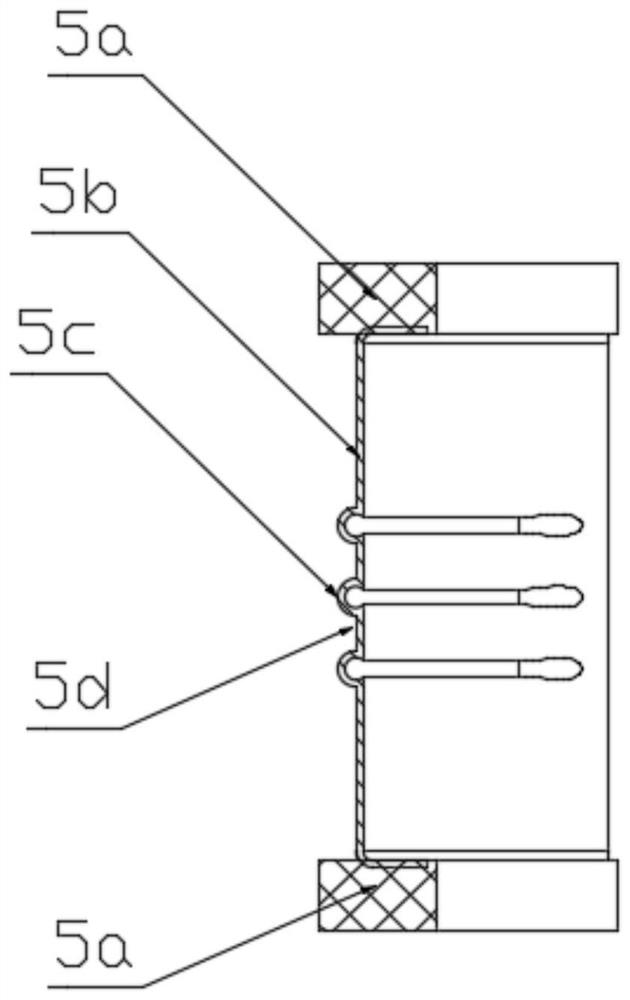

[0040] Among them, such as Figure 2 to Figure 4 As shown, the bushing 5 includes a steel ring 5b and a rubber block 5a, a...

Embodiment 2

[0048] refer to figure 1 with Figure 8 As shown, the gap adjustment method corresponding to the above-mentioned steering gear gap adjustment mechanism includes the following steps:

[0049] (1) Adjust the initial clearance of the steering gear by adjusting the initial position of the adjusting screw plug, and pre-compress the bushing. At this time, the rubber block of the bushing undergoes compression deformation, and the steel ring undergoes certain buckling deformation, so that the working force of the bushing - the displacement curve is in the linear segment;

[0050] (2) There is a gap between the gear and the rack due to work wear or the rack moves back and forth in the radial direction when the vehicle is driving on a bumpy road;

[0051] (3) The rack moves to the left in the radial direction (that is, away from the gear direction), pushing the pressing block to move to the left, compressing and deforming the bushing, generating axial force, restraining the pressing b...

Embodiment 3

[0056] A vehicle is equipped with a steering gear, and the steering gear is provided with the steering gear clearance adjustment mechanism of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com