Plastic bottle sorting machine

A technology for plastic bottles and bottle unscrambler, applied in the field of unscramblers, can solve the problems affecting the working efficiency of plastic bottles, restricting the application of unscramblers, and covering a large area, so as to improve the speed of unscrambler, light weight, and cover an area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

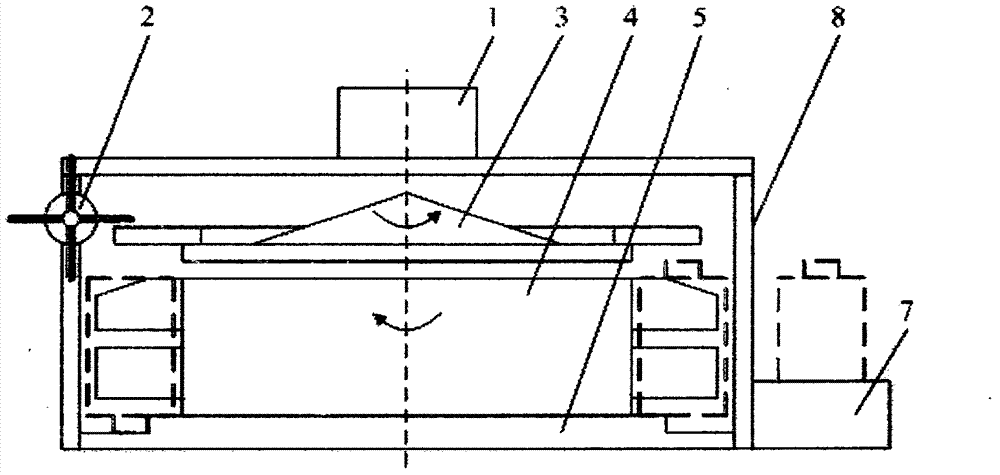

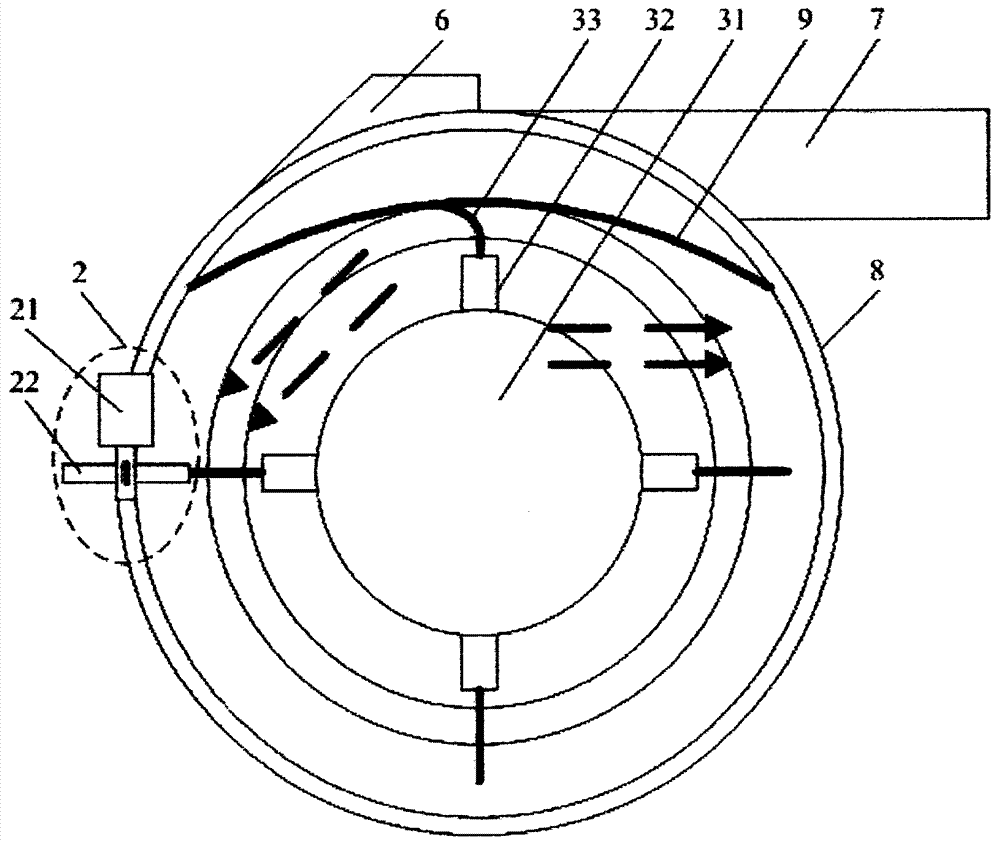

[0043] The plastic bottle unscrambler of the present embodiment, structural schematic diagram is as figure 1 shown. The plastic bottle unscrambler is provided with a fan 1, a bottle shifting mechanism 2, a turntable 3, a working position swivel 4 and a bottom plate 5 in sequence from top to bottom, and the bottle turning device 6 and the bottle outlet 7 are sequentially rotated along the working position swivel 4 direction, and set at the same height as the working position swivel 4, the turntable 3 is set horizontally, and is opposite to the rotation direction of the working position swivel 4, the outer shell 8 is connected to the outside of the base plate 5, and the turntable 3, the working position swivel 4 and the bottom plate 5; plastic bottles enter the working position of the working position swivel 4 under the action of the fan 1 and the bottle-pushing mechanism 2, and the plastic bottles placed in the correct direction are directly Discharged from the bottle outlet 7...

specific Embodiment 2

[0053] In the plastic bottle unscrambling machine of the present embodiment, the number of the bottle-moving mechanisms 2 is two, and the rotating shaft of the bottle-moving motor 21 of each bottle-moving mechanism 2 is provided with four bottle-moving fins 22, and two adjacent bottle-moving The included angle between the wings 22 and the rotating shaft of the bottle-moving motor 21 is a right angle. This design makes it more likely that the plastic bottle lying above the working position will be blown away by the bottle flipper 22, effectively preventing the plastic bottle and the plastic bottle at the working position from entering the bottle turner 6 together to cause bottle jamming .

specific Embodiment 3

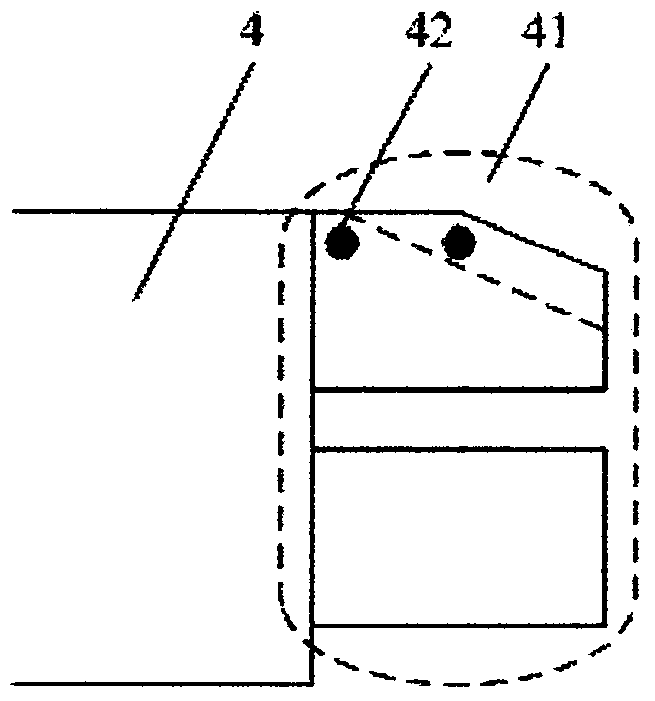

[0054] In the plastic bottle unscrambler of this embodiment, the number of the paddle groups 41 is an even number, and the paddle groups 41 are the same, and the upper paddles of the two adjacent paddle groups 41 are set one high and one low. The structural shape of sheet group 41 is as image 3 as shown, image 3 The solid line part represents the plectrum group 41 that the high position is set, and the dotted line part represents the plectrum set 41 that the low position is set. This design makes the plastic bottle in an inclined direction even if it is lying horizontally above the working position, which is conducive to entering the working position and improving the bottle feeding rate of the working position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com