Belt feeder without carrier roller

A feeder, rollerless technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased conveyor belt friction and dust, increased transmission resistance, and large maintenance, reducing friction. , The effect of reducing the conveying resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

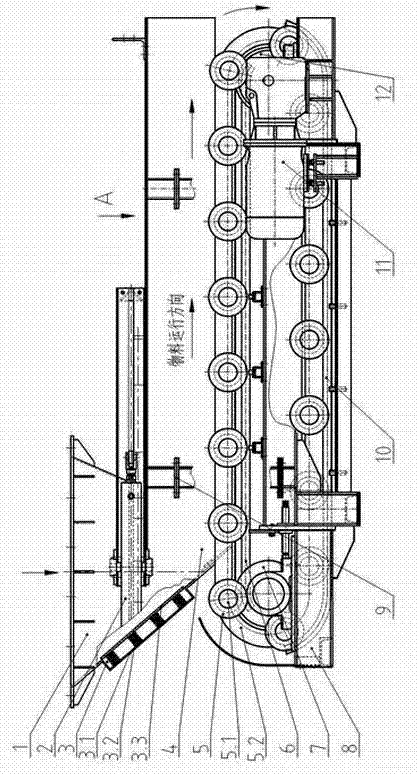

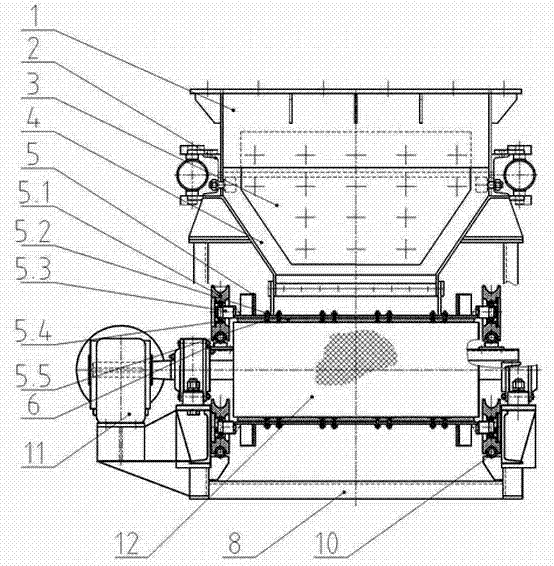

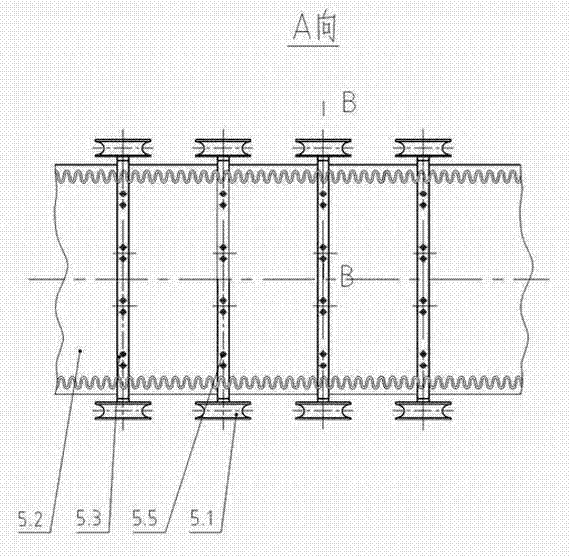

[0017] control Figure 1~4 , the rollerless belt feeder of the present invention is made up of hopper, gate, buffer device, tank body, roller belt, reversing roller, transmission roller, driving device and underframe, and the upper part of funnel 1 is connected with the feed bin mouth , the lower part is provided with a gate 2 and a tank body 4, a driving drum 12 and a redirecting drum 7 are arranged under the tank body 4, the bearing seats of the two drums are connected with the chassis 8, and a roller is arranged between the two drums The adhesive tape 5 and the output shaft of the driving drum 12 are connected with the reducer of the driving device 11, and the upper and lower parts of the bracket 9 are connected with the tank body 4 and the chassis 8 respectively. The roller shaft 5.3 and the bearing 5.4 are housed in the roller 5.1 of the roller tape 5, the roller shaft 5.3 is welded with the connecting plate 5.5, the connecting plate 5.5 is connected with the corrugated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com