Device for orienting sheets with articulated arm support

A technology of articulated arm and sheet, applied in the direction of positioning objects, transportation and packaging, object supply, etc., can solve problems such as small tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

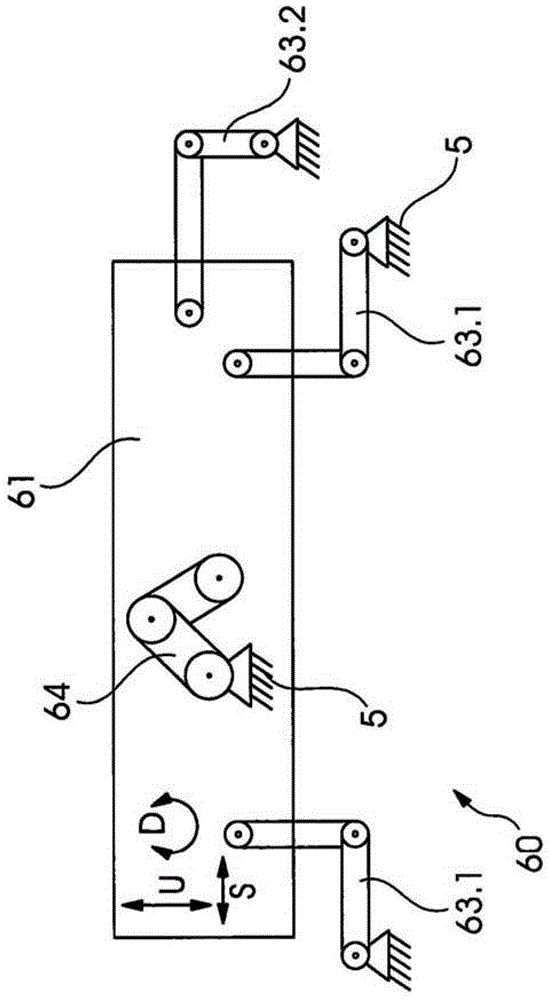

[0029] The sheets 6 from the sheet feeder 1 (eg Figure 2a shown in ) is oriented by means 60 for orienting.

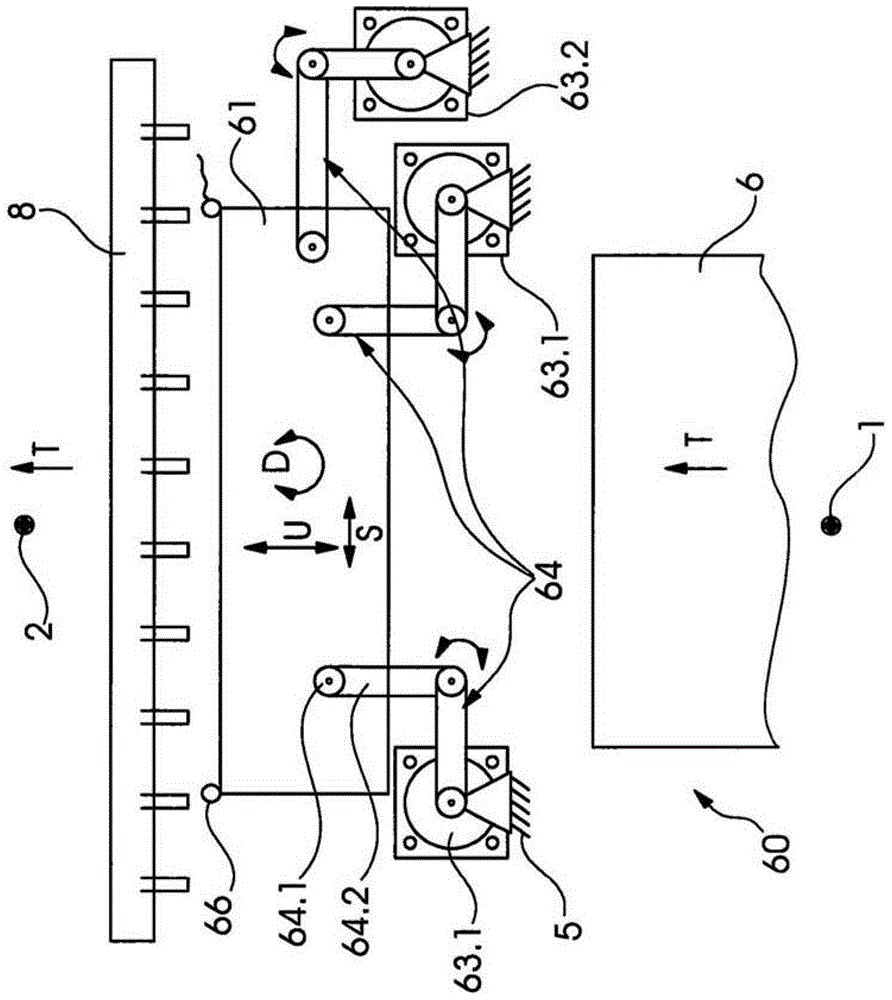

[0030] The alignment device 60 has an alignment device 61 which is movable in the circumferential direction U, in the lateral direction S and in the oblique direction D. FIG. The orientation device 61 is supported by three articulated arms 64 . Each articulated arm here has three joints 64.1 and two linkages 64.2. The first joint 64.1 is rotatably connected with the machine frame 5 . A second joint 64.1 rotatably connects the two links 64.2 to each other. The third joint 64 . 1 is rotatably connected to the orientation device 61 . The drives 63 are integrated in the individual articulated arms 64 . All drives 63 can be controlled independently of each other. Here two drive motors 63.1 and a further drive motor 63.2 are provided, which allow the orientation device 61 to move in the circumferential direction U and in the oblique direction D, and which allow the orie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com