Built-in pipe mould lifting appliance for dismounting extruding machine

A technology with a built-in tube and extruder, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of not being able to replace the inner and outer tube molds in time, and achieves the advantages of convenient disassembly and assembly, simple structure, and small construction space requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

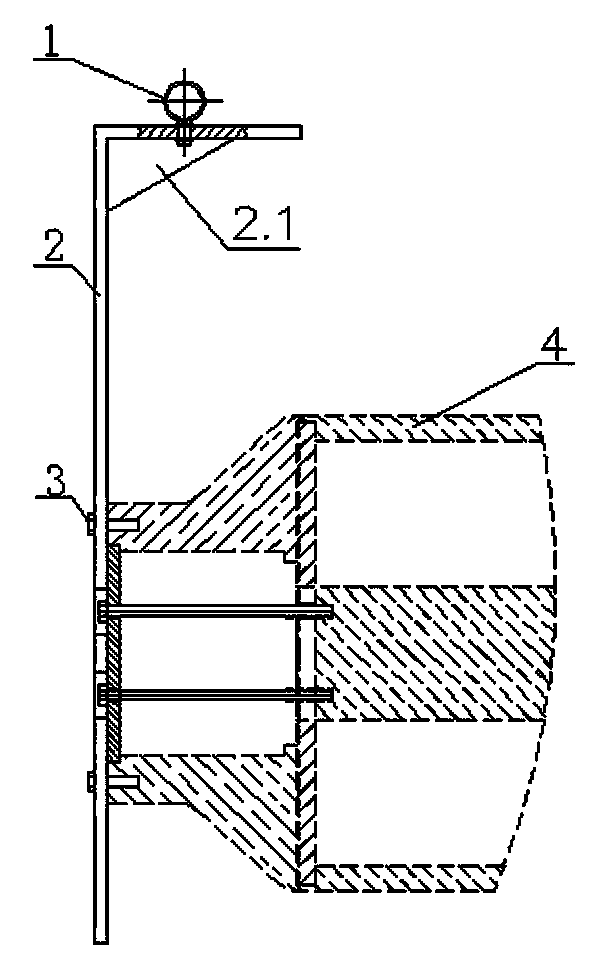

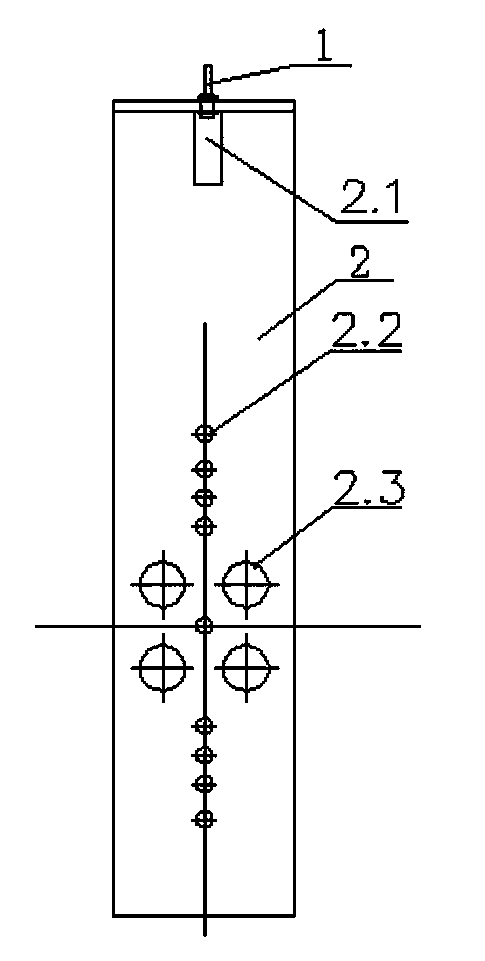

[0015] figure 1 The shown spreader is used to disassemble the built-in pipe mold of the extruder, which consists of a lifting ring 1, an angle iron 2, and a screw 3 to form a rigid spreader. The angle iron 2 is an inner bending plate with a short horizontal side and a long vertical side. A reinforcing rib 2.1 is provided at the inner corner, and a lifting ring 1 is fixedly installed on the horizontal side plate surface. 4 The positions of the screw holes on the end face are preset through holes 2.2 and process holes 2.3. The screw 3 runs through the through hole 2.2 on the vertical side of the angle iron 2 to connect the inner pipe mold 4 to form a detachable hoisting structure. In this embodiment, there are 4 process holes 2.3 in the center to accommodate the exposed bolt ends on the end surface of the inner pipe mold 4, figure 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com