A polyving akohol thin film and a manufacturing method thereof, a heat transfer printing stack using the thin film and a heat transfer printing method using the stack

A polyvinyl alcohol-based, manufacturing method technology, applied in the direction of copying/marking methods, chemical instruments and methods, printing, etc., can solve disadvantages and other problems, and achieve the effects of improving mold release, no whitening gloss, and whitening inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

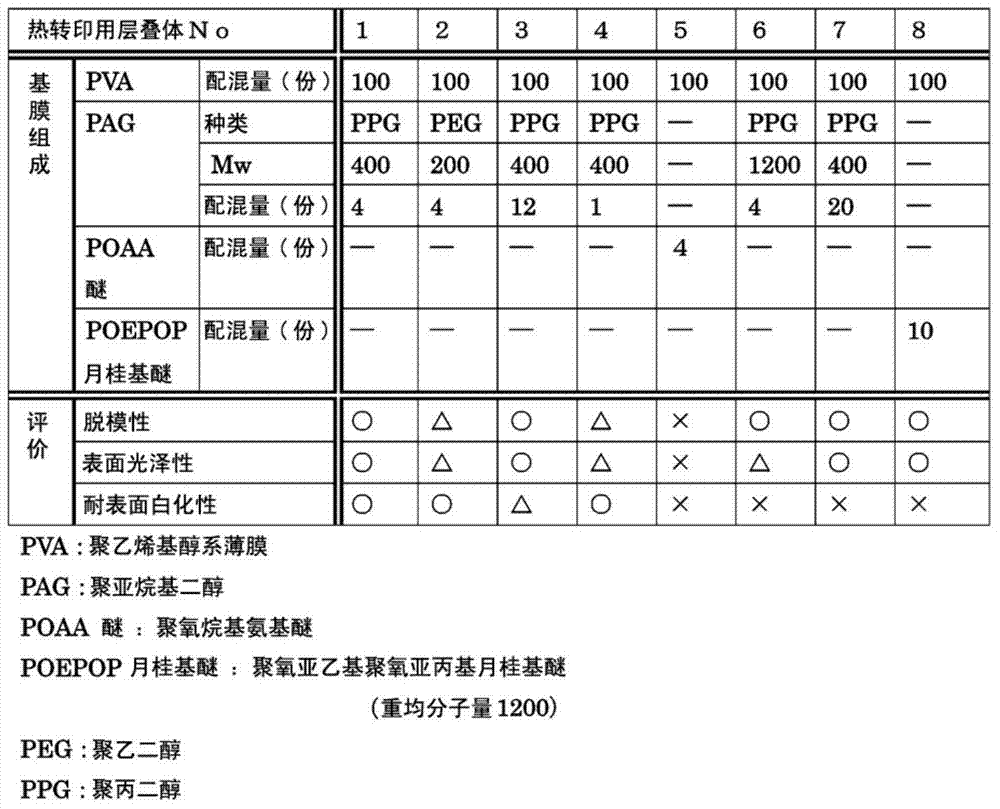

[0176] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited to the following examples unless the gist is exceeded.

[0177] However, "part" and "%" in an example refer to a basis of weight.

[0178] [Evaluation of samples for evaluation]

[0179] (1) Releasability

[0180] The releasability when the base film [I] was peeled from the sample for evaluation by hand was evaluated by the following reference|standard.

[0181] ◯: The base film can be easily peeled off.

[0182] Δ: Peeling from the base film was possible, but was accompanied by peeling noise.

[0183] ×: There was difficulty in peeling off the base film, and peeling marks remained on the surface of the protective layer.

[0184] (2) Surface gloss of the protective layer

[0185] After the base film [I] was peeled off for the evaluation sample, the fluorescent lamp was reflected on the surface of the protective layer (cured curable resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com