Waste heat boiler device of entrained bed gasifier

A technology of gasification furnace and entrained flow bed, which is applied in the field of waste boiler device of entrained bed gasification furnace, which can solve the problem of slag clogging of radiation waste boiler, the difficulty of popularizing the process technology of entrained flow bed with waste heat boiler, and the impossibility of gasification reaction, etc. problems, to achieve the effect of improving efficiency, processing and maintenance equipment with simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

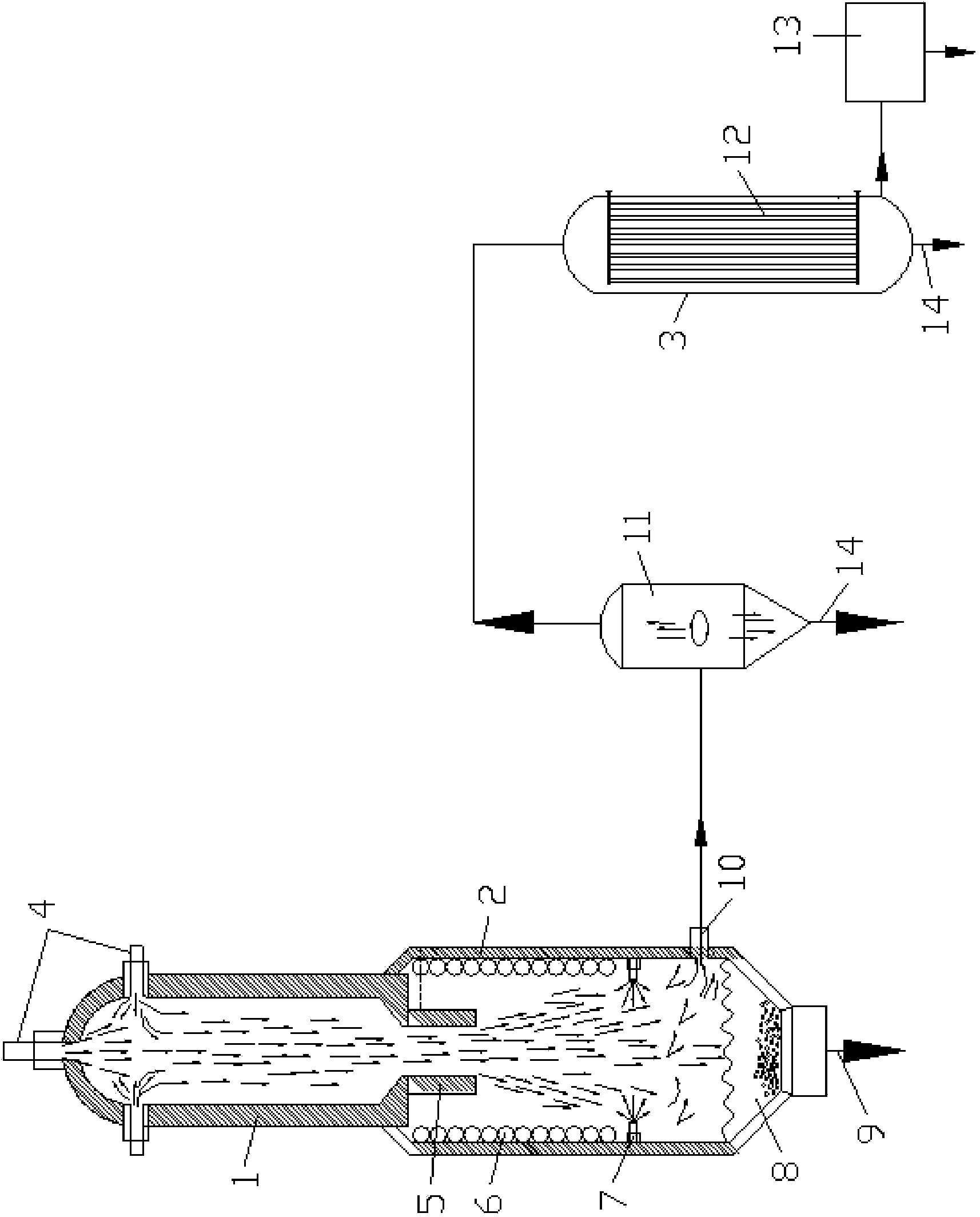

[0014] Such as figure 1 As shown, the waste boiler device of the entrained-flow gasifier of the present invention is mainly composed of a gasifier 1 , a radiation waste boiler 2 and a convection waste boiler 3 . Among them, the top of the gasifier 1 is provided with several burners 4 for spraying coal-water slurry, and the bottom has a tapered outlet. The radiant waste pot 2 is arranged below the gasifier 1, and a slag downcomer 5 is arranged in the middle of its top along the axial direction. The upper nozzle of the slag downcomer 5 communicates with the conical outlet of the gasifier 1. The lower nozzle is in communication with the radiation waste pot 2 . On the inner wall of the radiation waste pot 2, there is a water wall 6 for protecting the cylinder of the radiation waste pot 2 from high-temperature radiation along the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com