HBsAg aptamer screening method based on magnetic separation

A nucleic acid aptamer and screening method technology, applied in biochemical equipment and methods, DNA preparation, recombinant DNA technology, etc., can solve the problems of tediousness, easy loss in the separation process, and long separation operation time, so as to simplify the operation process, Ease of long-term storage and transportation, shortening of screening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The Fe 3 o 4 The preparation methods of magnetic nanoparticles include co-precipitation method, solvothermal method, soft template method, microemulsion method, thermal decomposition method and other physical or chemical methods. These methods can all be used in the present invention Fe 3 o 4 The preparation of magnetic nanoparticles and the preparation methods listed are only examples of the present invention, and cannot limit the scope of the present invention in any way.

[0030] The Fe 3 o 4 SiO 2 The carboxylation modification of the surface of magnetic nanoparticles is to firstly convert Fe 3 o 4 SiO 2 The surface of the magnetic nanoparticles is aminated, and then the surface is carboxylated using succinic anhydride.

[0031]The preserved carboxylated Fe 3 o 4 SiO 2 The organic solvent of the magnetic nanoparticles is ethanol, isopropanol, glycerol, acetone, n-butanol, tetrahydrofuran, or N,N-dimethylformamide (DMF) and other organic solvents. The li...

Embodiment 1

[0043] Embodiment 1 Carboxylated Fe 3 o 4 SiO 2 Preparation of Magnetic Nanoparticles

[0044] Fe 3 o 4 Magnetic nanoparticles were prepared by soft template method, Fe 3 o 4 SiO 2 Magnetic nanoparticles using seed polymerization and classical Preparation method; the specific preparation process is carried out with reference to Example 1 of the invention application CN102568728A. The prepared particles have the characteristics of uniform size and good dispersibility; and then carry out carboxylation modification on the surface.

[0045] The specific experimental process is as follows.

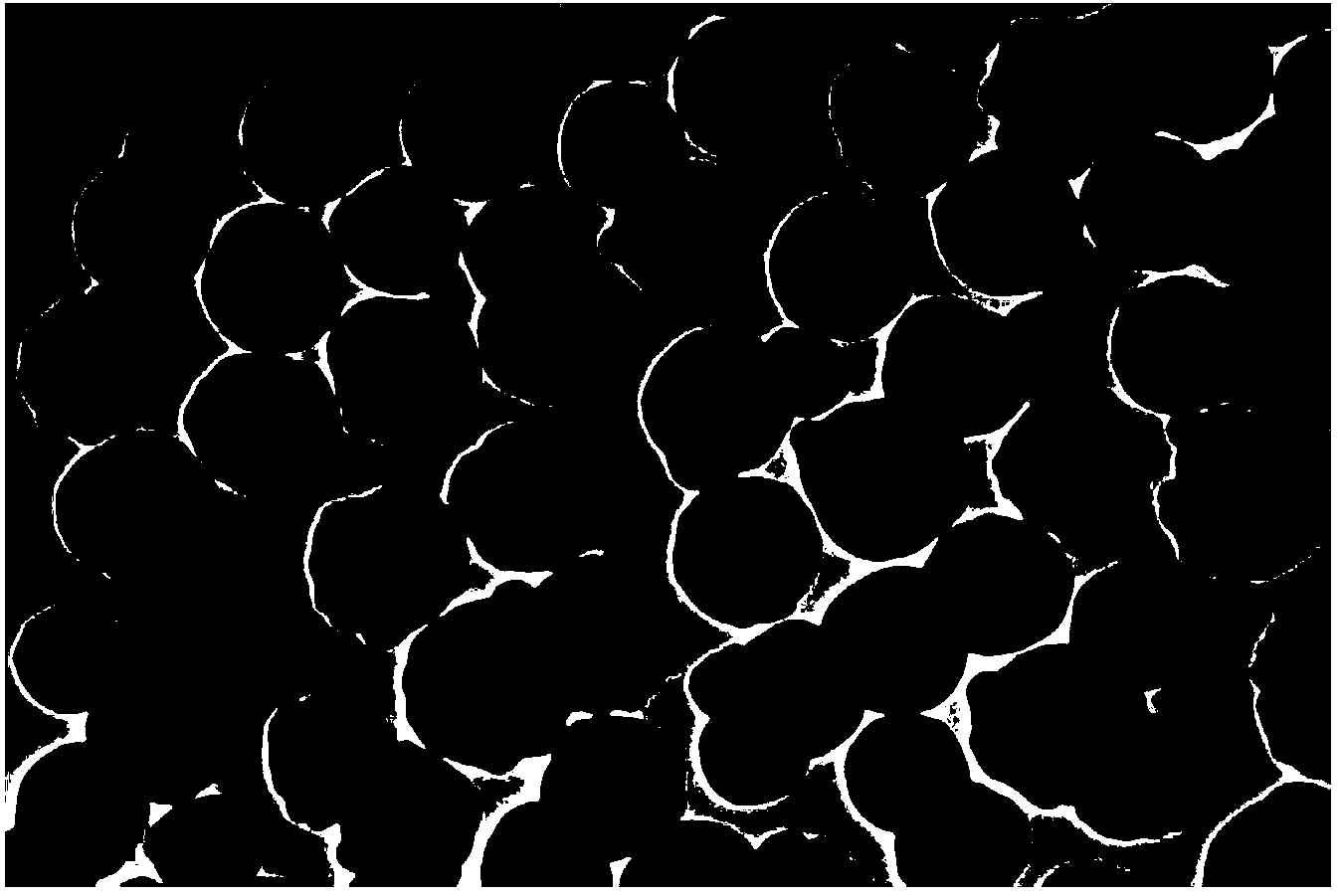

[0046] (1), first adopt the soft template method to prepare Fe with a particle size of about 500nm 3 o 4 Magnetic nanoparticles, followed by seed polymerization and classical Coated a layer of silicon shell on its surface to prepare Fe with a particle size of about 550nm 3 o 4 SiO 2 magnetic nanoparticles. figure 1 gives Fe 3 o 4 SiO 2 Transmission electron microscope image...

Embodiment 2

[0049] Embodiment 2 Carboxylated Fe 3 o 4 SiO 2 Magnetic nanoparticles activated and coupled to HBsAg by EDC in one step

[0050] (1), 2-(N-morpholine)-ethanesulfonic acid monohydrate (MES) buffer solution of 25mmol / L pH5 was used to clean the carboxylated Fe of Example 1 under the action of an external magnetic field 3 o 4 SiO 2 Magnetic nanoparticles 2 times to carboxylate Fe 3 o 4 SiO 2 Magnetic nanoparticles were dispersed in 5 mL of MES buffer.

[0051] (2) Before use, prepare a 10 mg / mL EDC solution with a 25 mmol / L pH5 MES solution stored at 4°C, and take the carboxylated Fe dispersed in the MES 3 o 4 SiO 2 Add 100 μL of EDC solution to 1 mL of magnetic nanoparticles, and shake slowly at 37° C. for 30 min.

[0052] (3) Discard the supernatant under the action of a magnetic field, wash with 25mmol / L pH5 MES buffer for 3 times, wash away the EDC not involved in the activation reaction, and obtain activated carboxylated Fe 3 o 4 SiO 2 magnetic nanoparticles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com