Method for smelting hollow billet steel ingot by using ingot stripping type electroslag furnace

An electroslag furnace and hollow tube technology, applied in the field of iron and steel metallurgy, can solve the problems of unfavorable quality and production efficiency of pipe fittings, difficulty in ensuring the concentricity of inner and outer holes and uniformity of wall thickness, etc., so as to reduce perforation links, ensure uniformity, The effect of improving quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

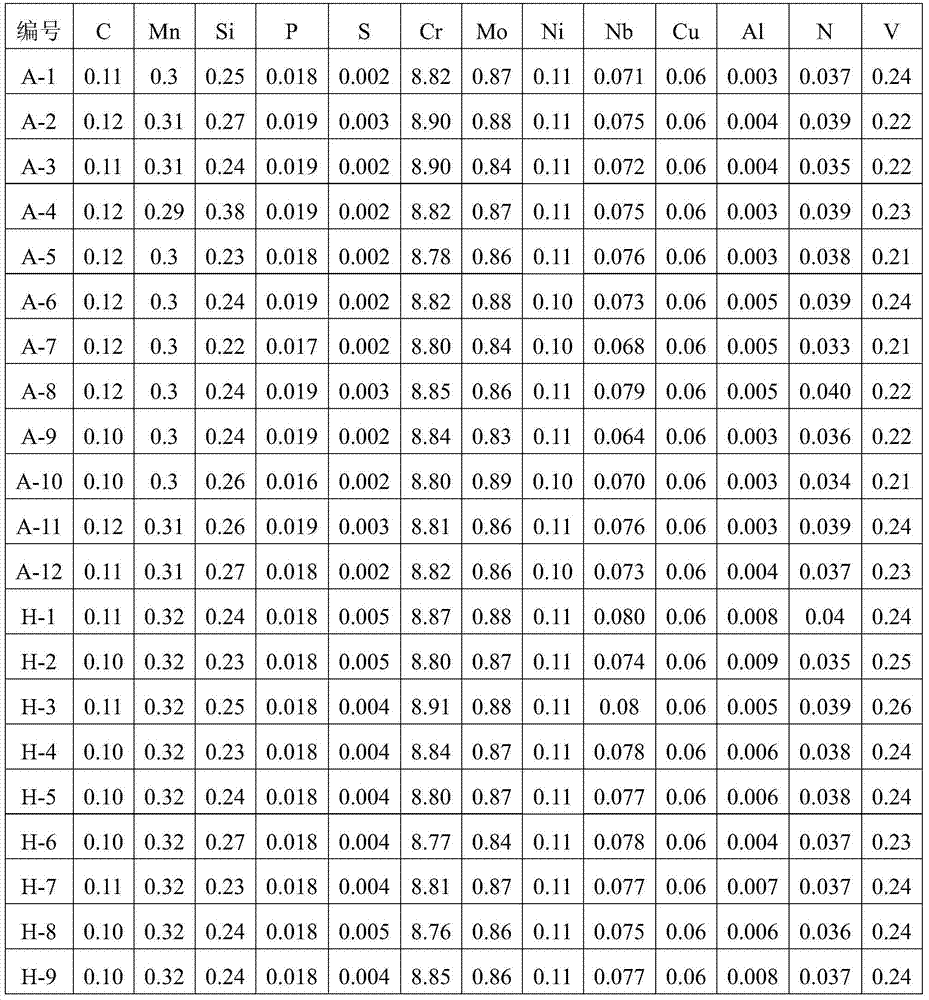

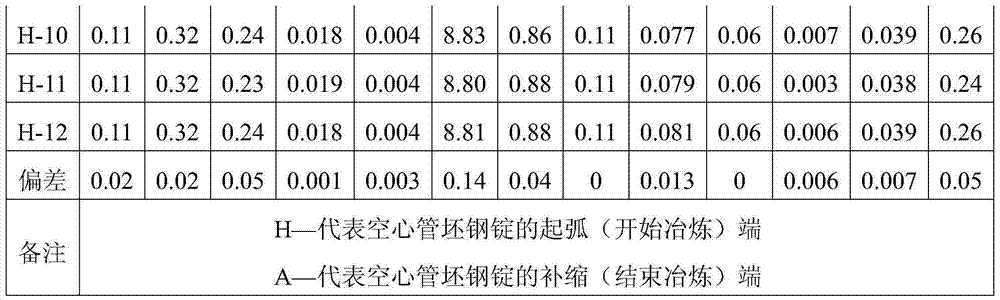

[0015] The method for smelting a hollow tube billet steel ingot by an ingot-pulling electroslag furnace according to the present invention will be described in detail below in conjunction with examples.

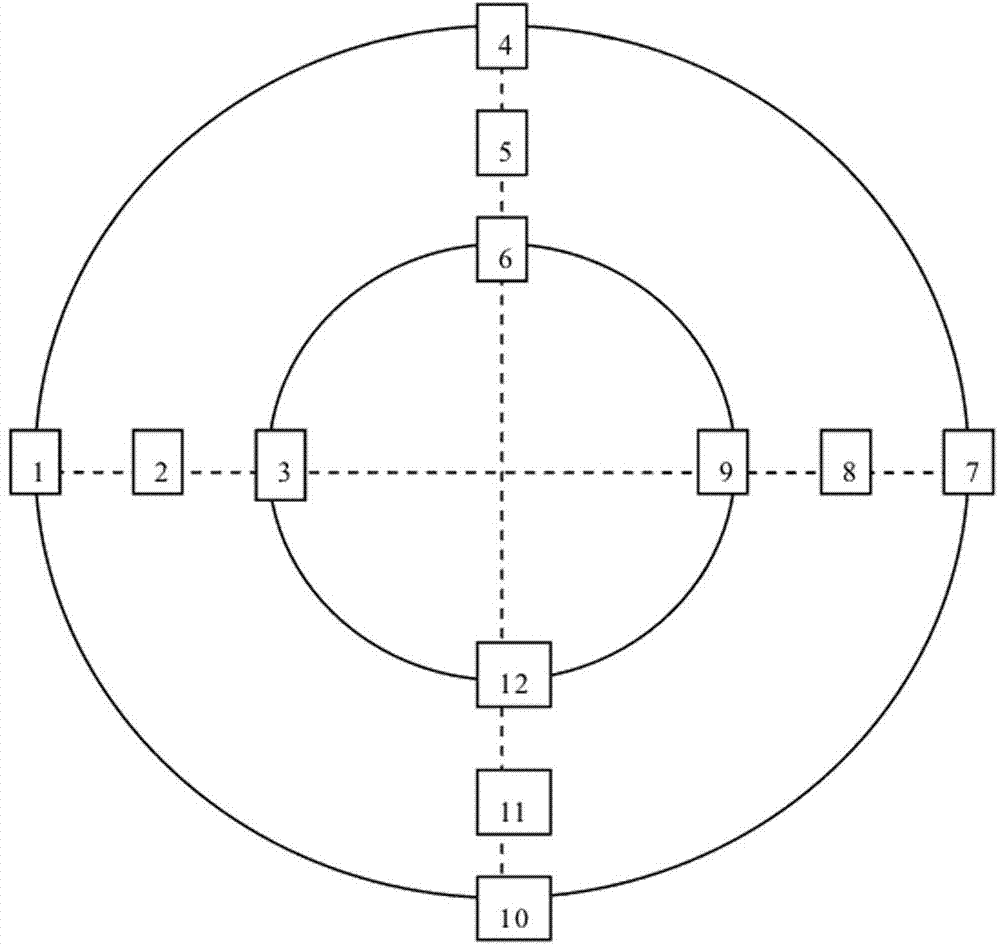

[0016] The general ingot-pulling electroslag furnace is equipped with an external mold and a bottom water tank, and the smelted steel ingot is drawn out through the downward movement of the bottom water tank and the external mold is kept still, then the molten steel can be cooled under the forced cooling of the external mold. Gradually solidify and crystallize from the outside to the inside to form steel ingots, but it cannot be used to produce hollow billet steel ingots.

[0017] In addition to the structure and characteristics of the general ingot-pulling electroslag furnace, the ingot-pulling electroslag furnace used in the present invention is also equipped with an inner mold, which can make the center of the molten steel form a size equal to that of the inner mold. Or a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com